A smart drying rack

A clothes drying rack and intelligent technology, applied in the field of clothes drying racks, can solve the problems of clothes getting wet in the rain and difficult to dry clothes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

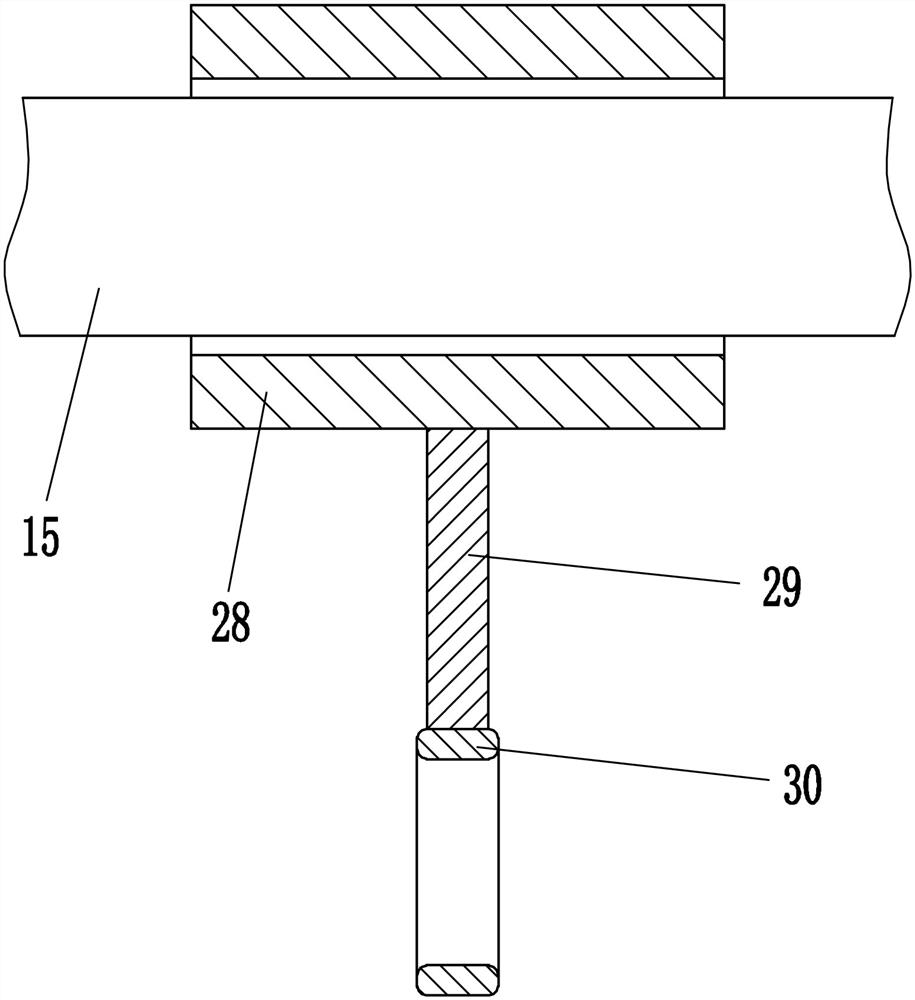

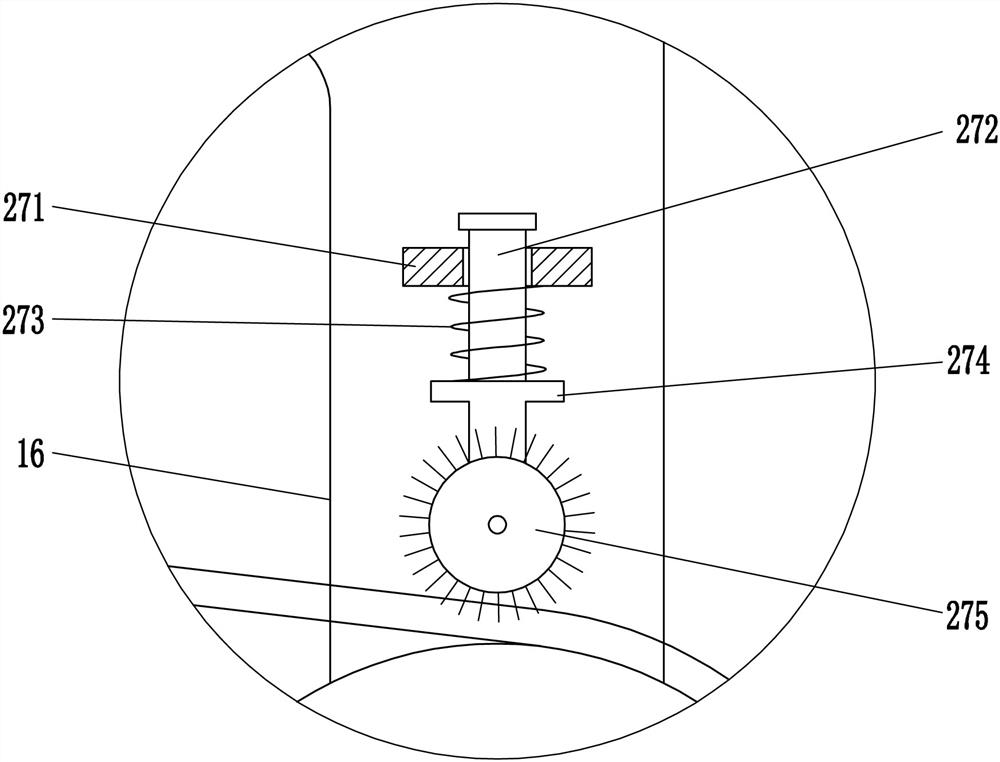

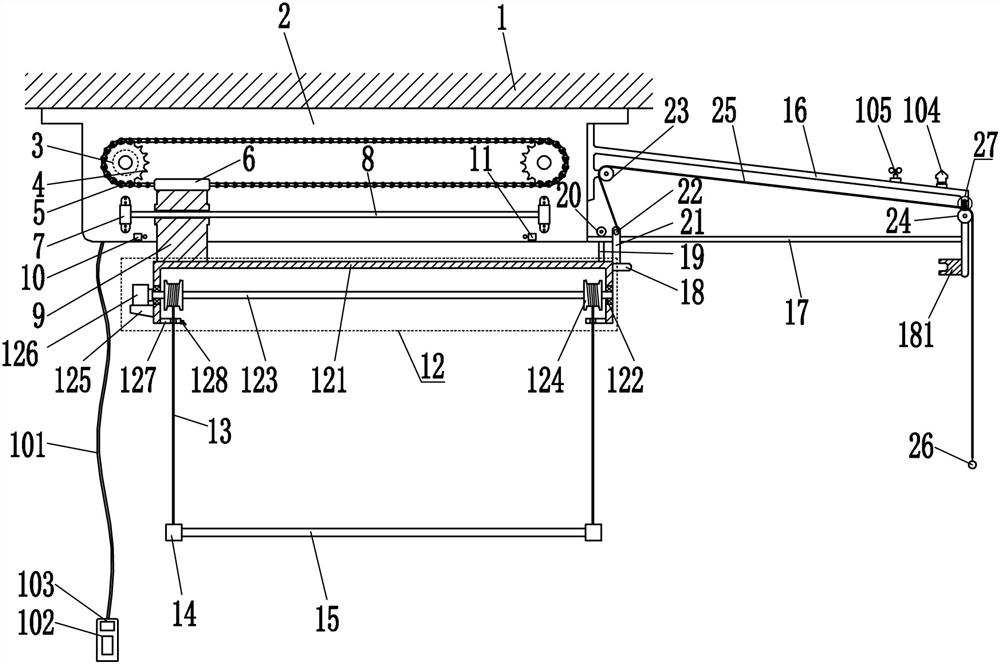

[0019] A smart drying rack, such as Figure 1-5 As shown, it includes connecting wire 101, control box 102, LCD display system 103, raindrop sensor 104, wind speed sensor 105, mounting plate 2, first motor 3, sprocket 4, chain 5, connecting block 6, bushing seat 7 , guide rod 8, guide plate 9, first travel switch 10, second travel switch 11, lifting mechanism 12, pull rope 13, shelf plate 14, hanging rod 15, wedge bracket 16, guide rail plate 17, intubation tube 18, card The block 181, the vertical support 19 and the guide wheel 20, the first motor 3 is bolted on the upper left side of the front side of the mounting plate 2, and there are two sprockets 4. The left sprocket 4 is connected with the output shaft of the first motor 3, and the right The square sprocket 4 is rotatably connected to the upper right upper part of the front side of the mounting plate 2, a chain 5 is wound between the two sprockets 4, a connecting block 6 is connected to the chain 5, and there are two bu...

Embodiment 2

[0021] A smart drying rack, such as Figure 1-5As shown, it includes connecting wire 101, control box 102, LCD display system 103, raindrop sensor 104, wind speed sensor 105, mounting plate 2, first motor 3, sprocket 4, chain 5, connecting block 6, bushing seat 7 , guide rod 8, guide plate 9, first travel switch 10, second travel switch 11, lifting mechanism 12, pull rope 13, shelf plate 14, hanging rod 15, wedge bracket 16, guide rail plate 17, intubation tube 18, card The block 181, the vertical support 19 and the guide wheel 20, the first motor 3 is bolted on the upper left side of the front side of the mounting plate 2, and there are two sprockets 4. The left sprocket 4 is connected with the output shaft of the first motor 3, and the right The square sprocket 4 is rotatably connected to the upper right upper part of the front side of the mounting plate 2, a chain 5 is wound between the two sprockets 4, a connecting block 6 is connected to the chain 5, and there are two bus...

Embodiment 3

[0024] A smart drying rack, such as Figure 1-5 As shown, it includes connecting wire 101, control box 102, LCD display system 103, raindrop sensor 104, wind speed sensor 105, mounting plate 2, first motor 3, sprocket 4, chain 5, connecting block 6, bushing seat 7 , guide rod 8, guide plate 9, first travel switch 10, second travel switch 11, lifting mechanism 12, pull rope 13, shelf plate 14, hanging rod 15, wedge bracket 16, guide rail plate 17, intubation tube 18, card The block 181, the vertical support 19 and the guide wheel 20, the first motor 3 is bolted on the upper left side of the front side of the mounting plate 2, and there are two sprockets 4. The left sprocket 4 is connected with the output shaft of the first motor 3, and the right The square sprocket 4 is rotatably connected to the upper right upper part of the front side of the mounting plate 2, a chain 5 is wound between the two sprockets 4, a connecting block 6 is connected to the chain 5, and there are two bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com