A construction method for anti-sliding piles in emergency rescue engineering after damage to pile holes

An anti-slide pile and post-construction technology, which is applied in the direction of foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of secondary inclination, damage, and limitation of pile holes, achieve high soil stability, shorten construction period, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

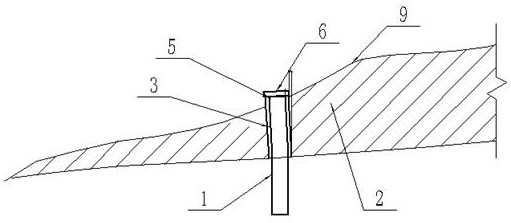

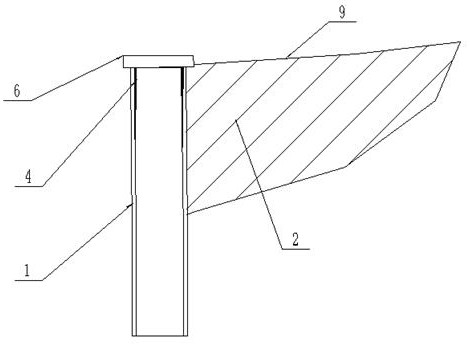

[0027] Embodiment 1: in step (1), as figure 2 As shown, before stripping the retaining wall 3 within the deformation depth range of the pile hole 5, first judge the vertical deformation offset of the pile hole 5, when the vertical deformation offset of the anti-sliding pile pile hole 5 is less than the When the thickness is high, the lock 6 at the top of the pile hole 5 is reserved, and the part of the retaining wall 3 within the range of the inclined deformation depth close to the slip layer 2 is grooved and repaired; Directly adopt the formwork 4 set on the retaining wall 3 to close the mold and keep the original retaining wall 3, so that the verticality of the corrected pile hole 5 is within the vertical deviation range specified by the design, so as to form the corrected pile hole 5; The shifting layer 2 refers to the side of the protective wall 3 directly impacted by the sliding layer 2 , and the distance away from the sliding layer 2 refers to the side of the protective...

Embodiment 2

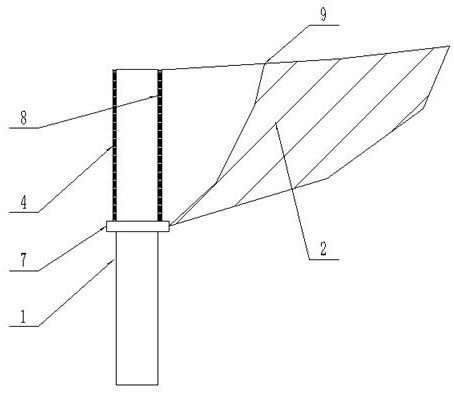

[0033] Embodiment 2: in step (1), as image 3 As shown, before stripping the retaining wall 3 within the deformation depth range of the pile hole 5, the vertical deformation offset of the pile hole 5 is first judged. At the same time, first remove the deformed locking opening 6, and then excavate the slip layer near the anti-slide pile hole 5 according to the deformation depth of the anti-slide pile hole 5, and the excavation depth corresponds to the deformation depth of the retaining wall 3 to form On the working face, dismantle the retaining wall section of the deformation depth, and then build a lock 7 at the upper end of the retaining wall 3 left after the removal, and the part from the newly built lock 7 to the design top elevation constitutes the empty section 8; The formwork 4 matching the aperture of the hole 5 is used for support, and the lower part of the formwork 4 is fixed on the upper surface of the new lock 7. The top elevation of the formwork 4 is equal to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com