Rotary locking quick docking device

A docking device and fast technology, applied in the direction of connecting components, mechanical equipment, etc., to achieve the effect of fast separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

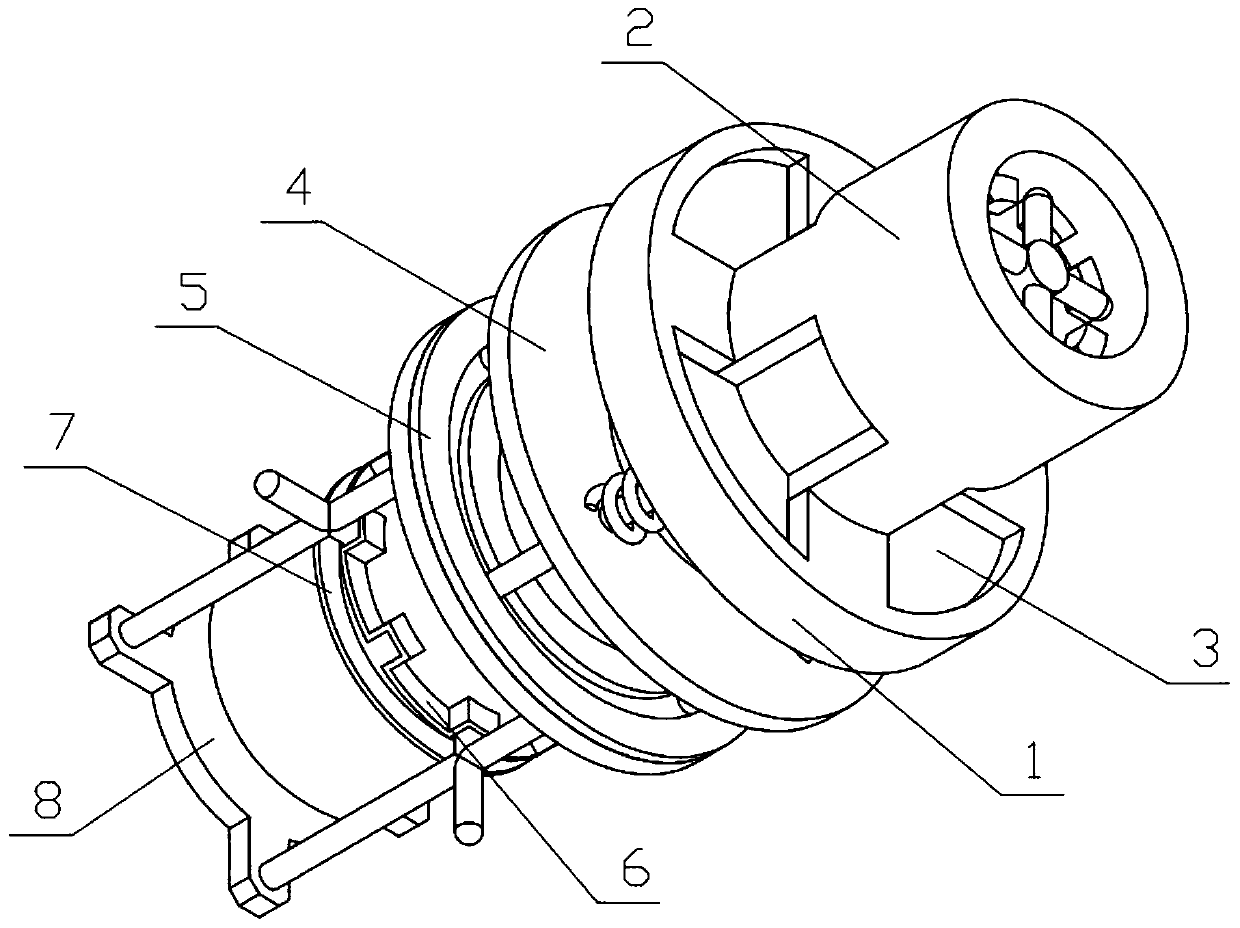

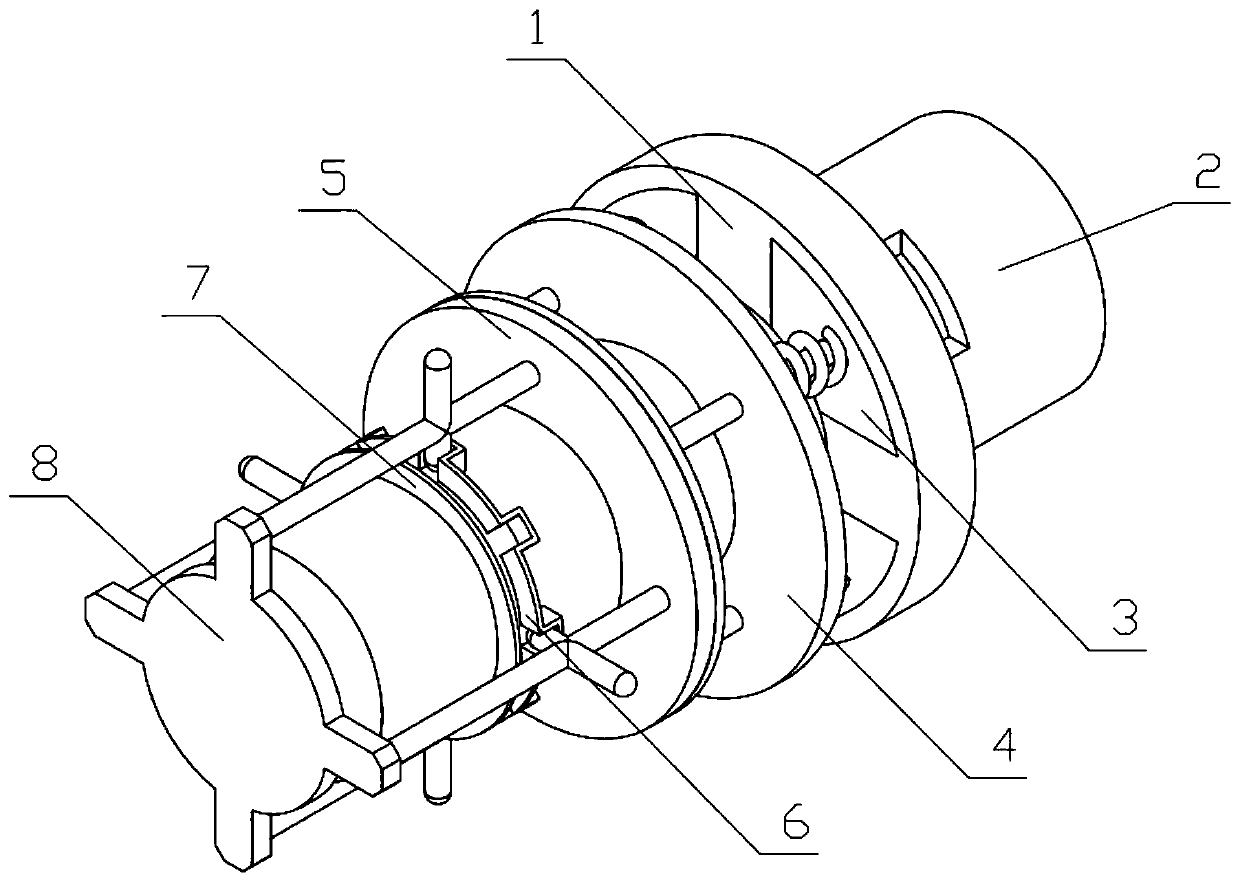

[0036] Combine below Figure 1-15Describe this embodiment, a quick docking device for rotation and locking, including a connecting frame I1, a connecting frame II2, a locking frame 3, a support ring 4, a sliding mechanism 5, a snap ring 6, a limit ring 7 and a disassembly mechanism 8, The connecting frame II2 is clamped on the connecting frame I1, the support ring 4 is fixedly connected to the connecting frame I1, the locking frame 3 is slidably connected to the supporting ring 4, and a compression spring is arranged between the locking frame 3 and the supporting ring 4 , the locking frame 3 is slidably connected to the connecting frame Ⅰ1 to limit the rotation of the connecting frame Ⅱ2, the sliding mechanism 5 is gap-fitted on the connecting frame Ⅰ1, the lower end of the locking frame 3 is rotatably connected to the sliding mechanism 5, and the snap ring 6 and the limiting The positioning rings 7 are all fixedly connected to the connecting frame I1, a dismounting slideway i...

specific Embodiment approach 2

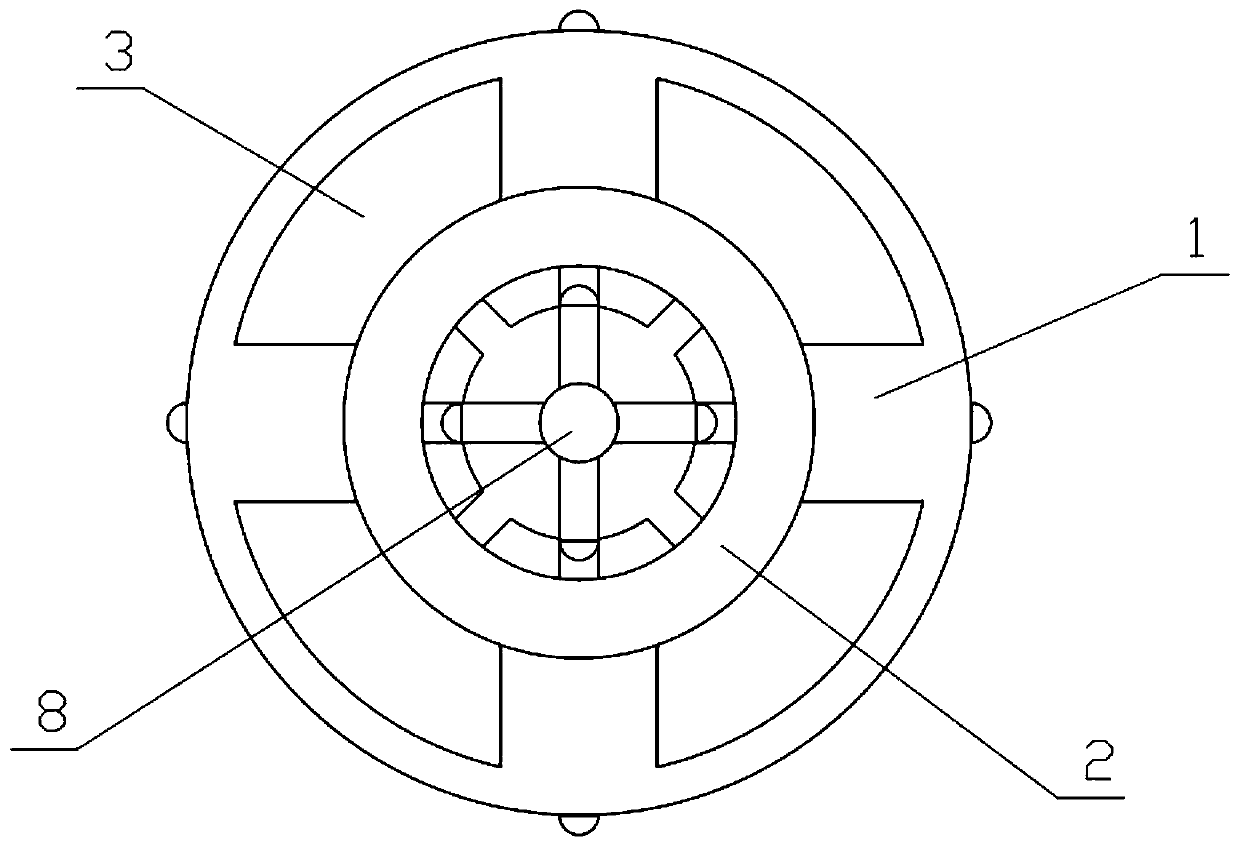

[0038] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain the first embodiment, the connecting frame I1 includes a connecting column 1-1, a connecting ring 1-2, a connecting baffle I1-3, a connecting baffle II1-4, and a clamping groove 1-5 and connecting slot 1-6, the lower end of the inner side of the connecting ring 1-2 is evenly fixed and connected in the circumferential direction with four connecting baffles Ⅰ1-3, and the inner sides of the four connecting baffles Ⅰ1-3 are all fixedly connected to the connecting column On 1-1, the upper end of the inner side of the connecting ring 1-2 is evenly fixed and connected in the circumferential direction with four connecting baffles II1-4, the connecting ring 1-2, four connecting baffles I1-3 and four connecting baffles II1- Four clamping grooves 1-5 are formed between 4, and connection clamping grooves 1-6 are formed between the four connecting baffles I1-3 and the four connecting baffles II...

specific Embodiment approach 3

[0040] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain the second embodiment, the connecting frame II 2 includes a connecting cylinder 2-1, a stop shoulder 2-2, a connecting board 2-3, a connecting clamping board 2-4 and Disassemble the push block 2-5, the upper end of the inner side of the connecting cylinder 2-1 is provided with a stop shoulder 2-2, and the lower end of the connecting cylinder 2-1 is uniformly fixed and connected in the circumferential direction with four connecting plates 2-3, and the four connecting plates 2-3 The outer side of the lower end of the plugboard 2-3 is fixedly connected with a connection clamp 2-4, and the four connection clamps 2-4 are respectively stuck in the four connection clamp grooves 1-6, and the inner circumference of the stop shoulder 2-2 There are eight dismounting push blocks 2-5 that are uniformly fixedly connected, and eight dismounting push grooves are formed between the eight dismountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com