Device for separating oil from waste water of mess hall

A waste water and oil separation technology, applied in grease/oily substance/float removal device, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve difficult cleaning, waste of resources, production and living losses and other problems, to achieve the effect of simple, clean and fast separation of the separated oil layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

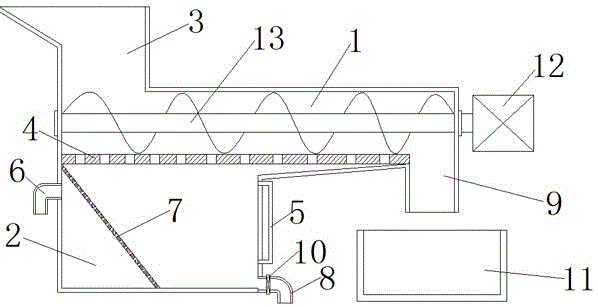

[0010] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0011] figure 1 Shown is a canteen wastewater grease trap provided by the present invention, comprising a swill inlet 3 and a slag outlet 9, the lower end of the swill inlet 3 is provided with a slag delivery chamber 1, and a screw 13 is arranged in the slag delivery chamber 1, and the screw 13 Connected with the motor 12, the lower end of the screw rod 13 is provided with a first filter plate 4, the lower end of the first filter plate 4 is provided with an oil-water sump 2, and the upper end of the side wall of the oil-water sump 2 is provided with an oil outlet 6, and the oil outlet begins The wall of the oil-water sump 2 of 6 is provided with an inclined second filter plate 7, the bottom end of the oil-water sump 2 is provided with a water outlet 8, and the second filter plate 7 is arranged between the oil outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com