Automatic silicon slice separating device

An automatic separation and driving device technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problem of overlapping multiple silicon chips, achieve rapid separation, improve work efficiency, and increase production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

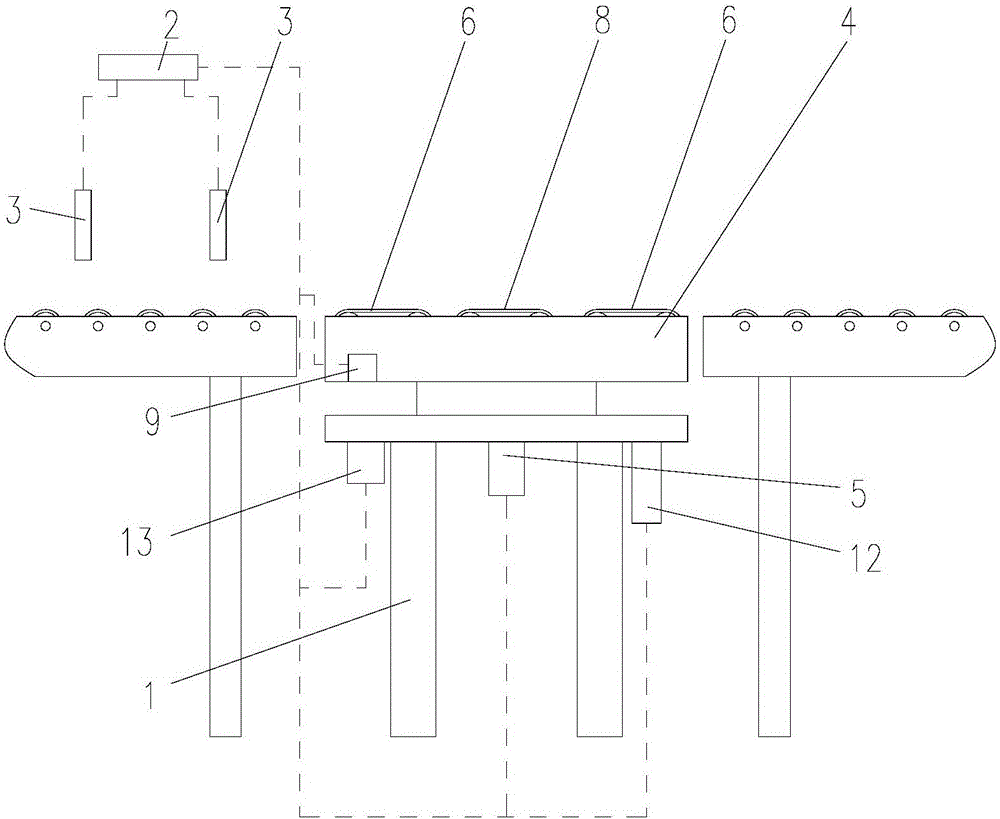

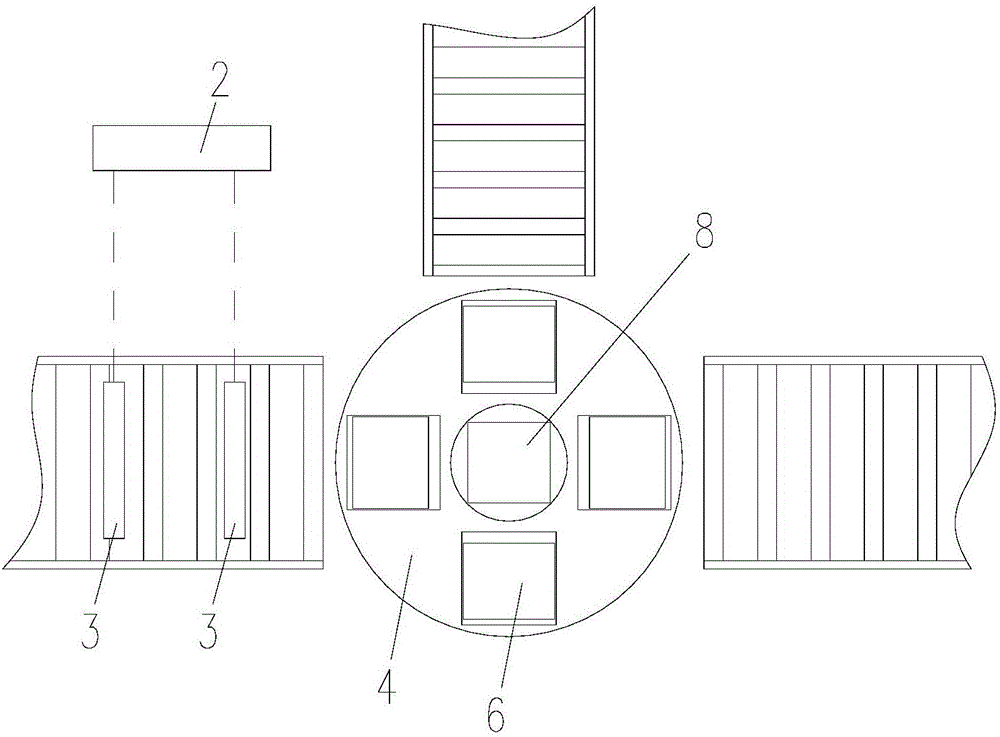

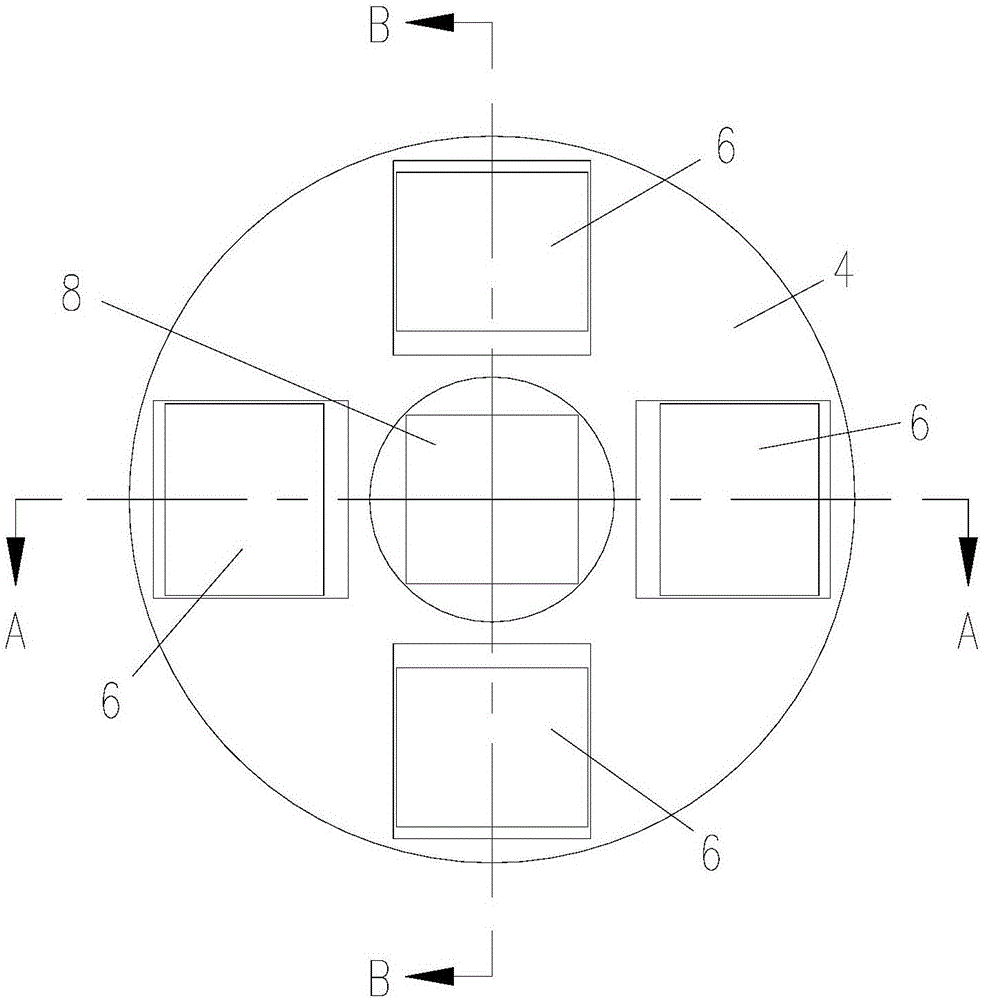

[0019] Such as Figure 1-5 As shown, a silicon wafer automatic separation device includes a frame 1, a control unit 2 and a laser distance measuring sensor 3, the frame 1 is provided with an annular support 4 for rotation, and the frame 1 is provided with a The first driving device 5 for the rotation of the annular support 4, four groups of first conveyor belts 6 are distributed along the circumference on the annular support 4, grooves are provided on the annular support 4, and the first conveyor belts 6 are arranged in the grooves. In the groove, the first conveyor belt 6 is provided with a driven friction wheel 7, and the frame 1 is provided with two sets of first driving friction wheels 10, and a second driving friction wheel 10 is arranged between the first driving friction wheels 10. Friction wheel 11, the rotation direction of the first driving friction wheel 10 and the second driving friction wheel 11 is opposite, the first driving friction wheel 10 and the second drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com