Device for separation of oil-water-residue mixture and marking of waste oil

A technology of oil-water mixture and mixture, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, analysis by chemical reaction of materials, etc. High-efficiency separation of water and slag, low separation purity, etc., to avoid food hygiene and safety problems, complete separation, and simple structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

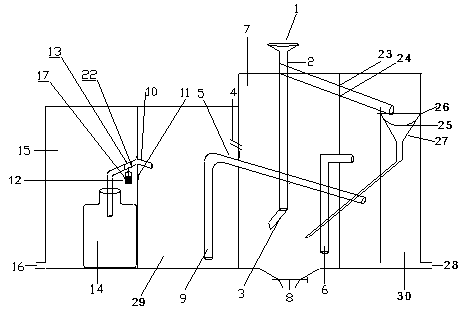

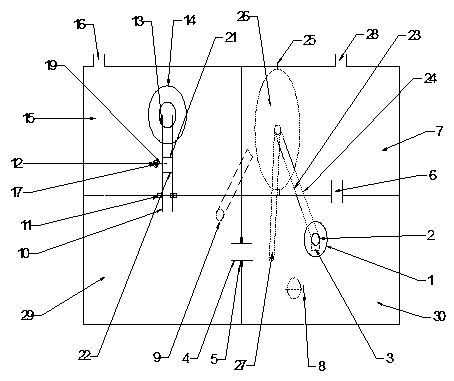

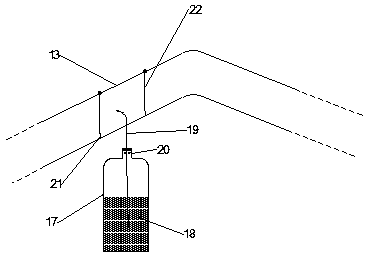

[0021] Embodiment of the present invention: a device for separating oil-water slag mixture and marking waste oil, as attached Figure 1-3 As shown, there are adjacent residue collection chamber 7, waste oil collection chamber 15, oil-water mixture separation chamber 29 and waste water collection chamber 30, wherein the residue collection chamber 7 and waste water collection chamber 30 are located in the middle of the wall A through hole is provided, and a waste water output pipe 6 is penetrated in the through hole to connect the two chambers, and a first oil outlet 4 is arranged on the wall adjacent to the residue collection chamber 7 and the oil-water mixture separation chamber 29 again, through which The first oil outlet 4 connects the two chambers, and the wall adjacent to the waste oil collectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com