Heat dissipation shock-proof structure

A shock-resistant, extended-section technology, applied in the direction of record carrier structural parts, instruments, record information storage, etc., can solve the problems of escape, poor thermal conductivity of foam, and easy damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

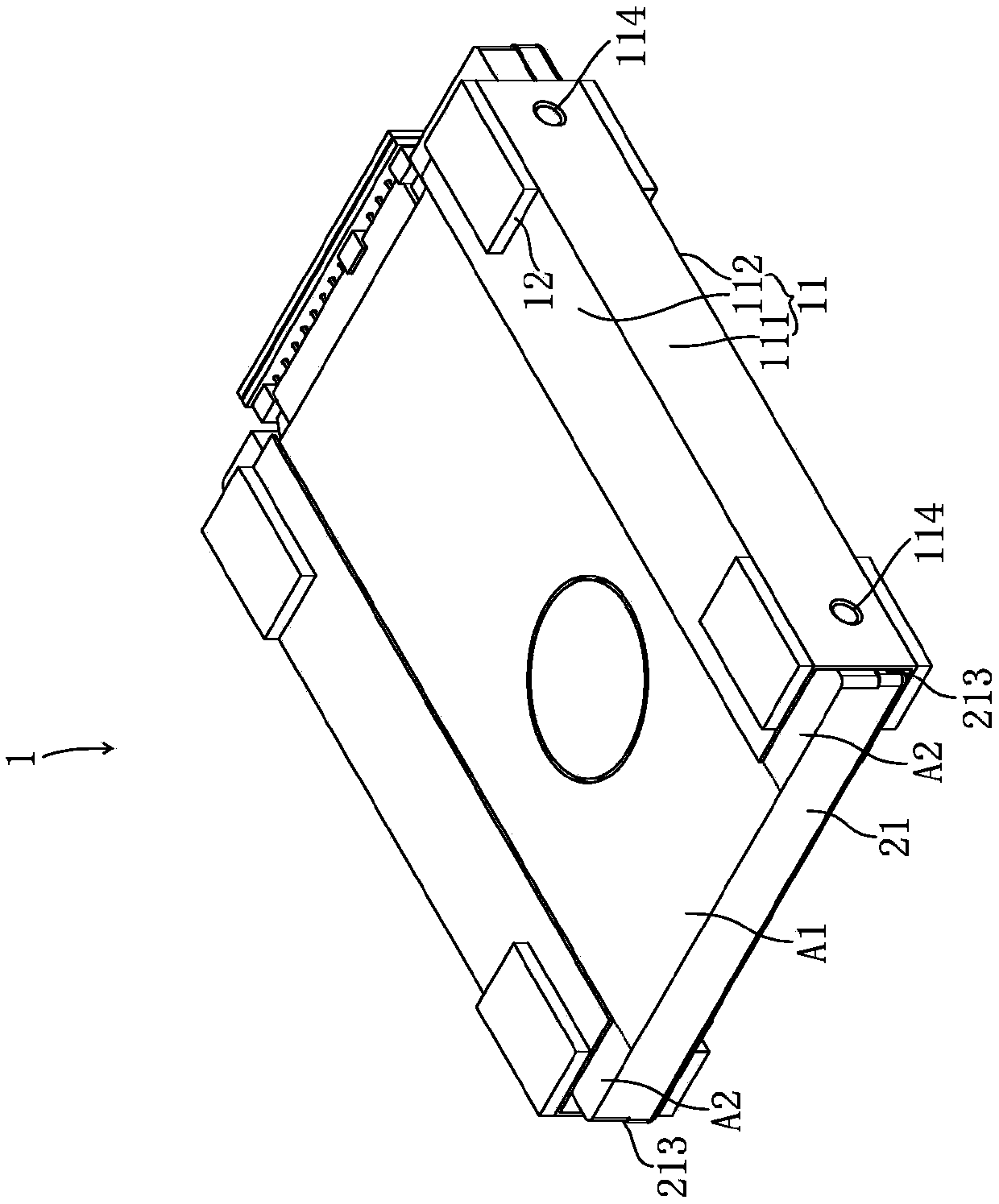

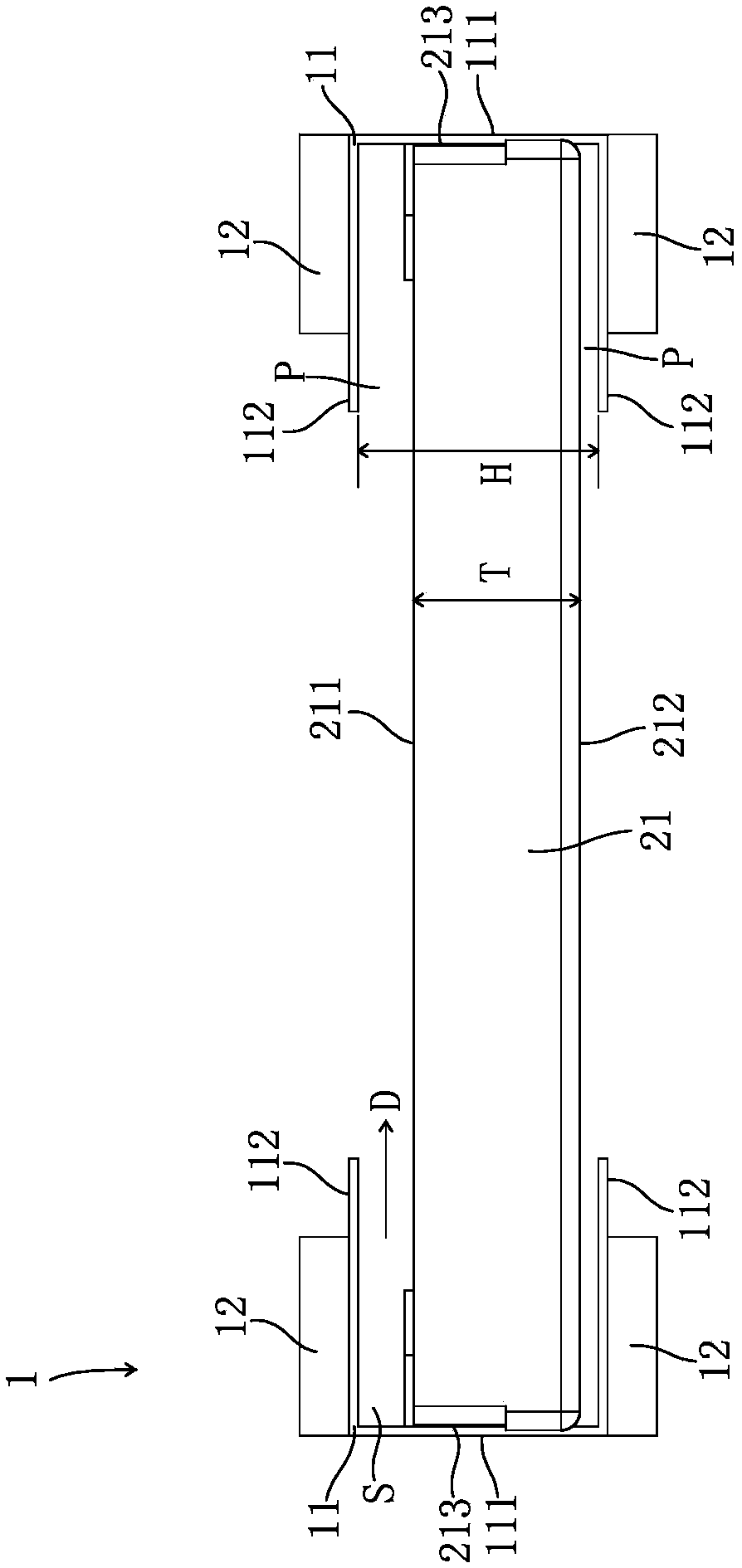

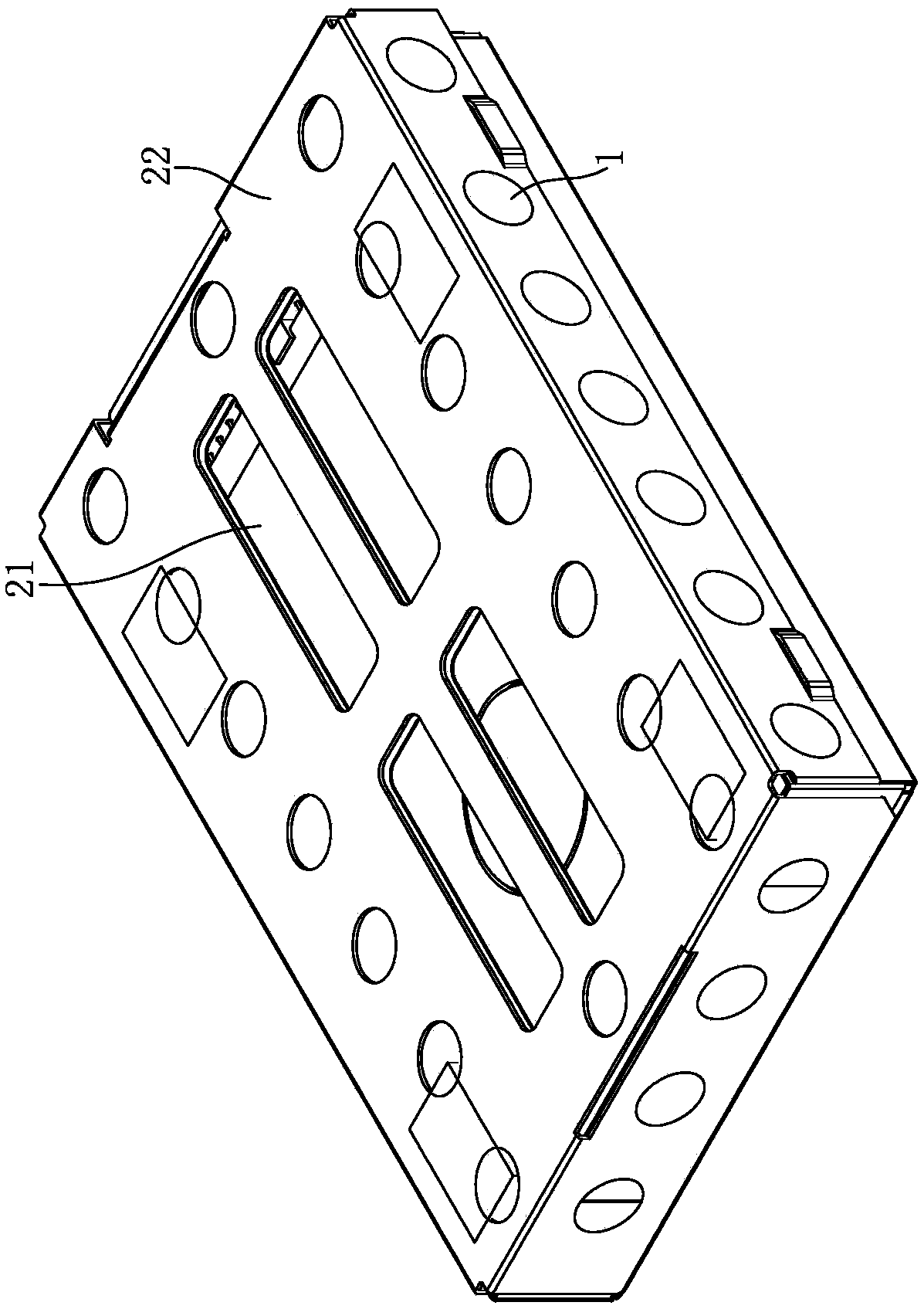

[0031] The heat dissipation and shockproof structure 1 of the present invention is used for an electronic module, wherein, please refer to figure 1 and figure 2 , is a schematic diagram showing the combination of the first embodiment of the present invention and a hard disk 21 of the electronic module (not shown in the figure). The heat-dissipating and shock-resistant structure 1 of this embodiment includes two supporting parts 11 and a plurality of elastic bodies 12 . The relationship between the components of the heat-dissipating and shock-resistant structure 1 and the electronic modules will be described in detail below.

[0032] These bearings 11 are respectively arranged on two opposite sides 213 of the hard disk 21. Since these bearings 11 and the hard disk 21 are connected in the same way, this embodiment only makes a connection relationship between one of the bearings 11 and the hard disk 21. illustrate. The carrier 11 has a fixed section 111 and two first extension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com