Filter press

A filter press and filter mechanism technology, applied in filtration and separation, membrane filters, fixed filter element filters, etc., can solve problems such as low production efficiency and filter cake falling, and achieve extended service life, sufficient filtration, and ease of use. Effects of Operation Controls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

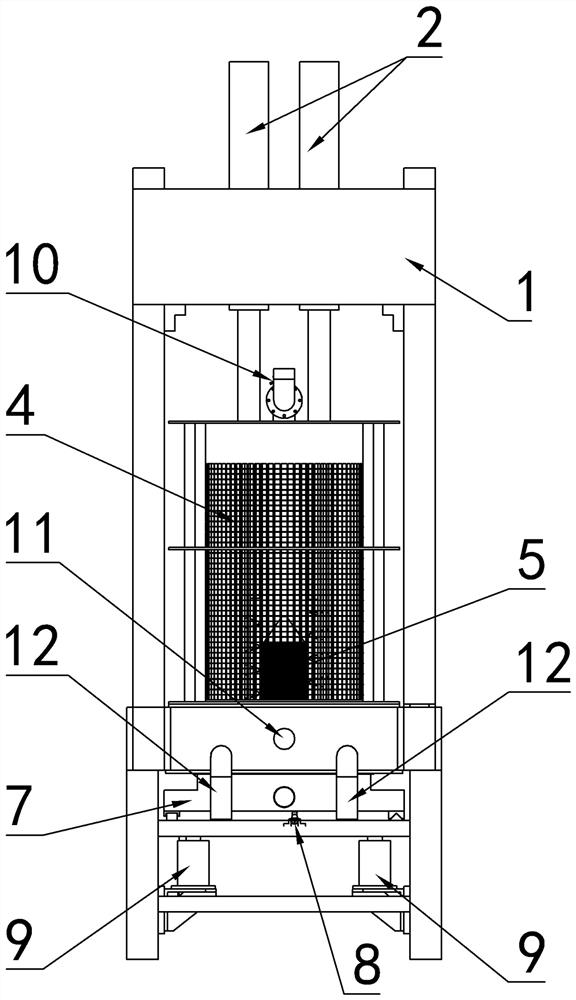

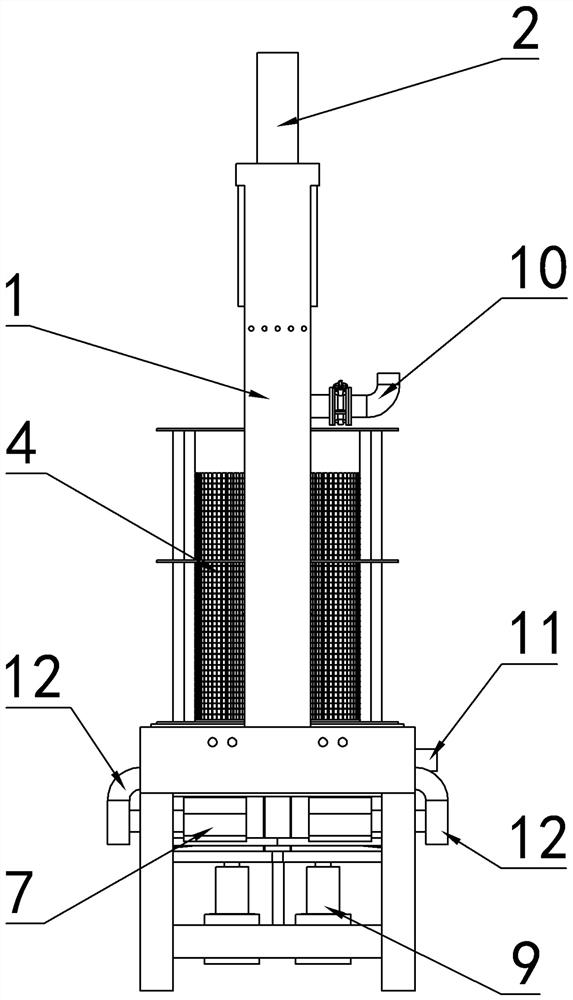

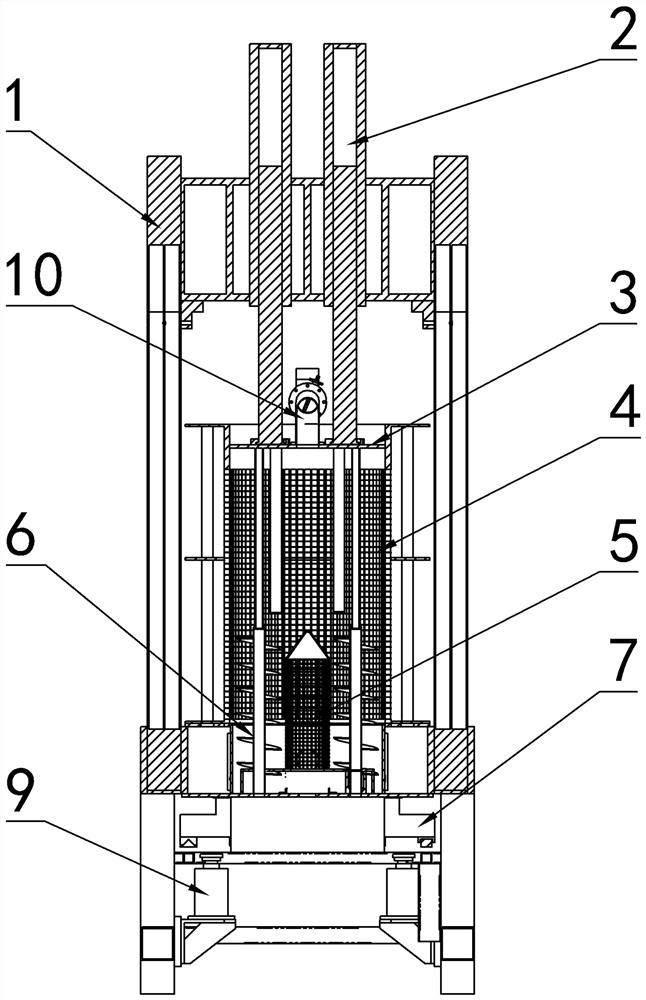

[0028] Example A filter press

[0029] Such as Figure 1 to Figure 4 As shown, the top pressing part and the bottom supporting part in the pressing mechanism of this embodiment cooperate with each other to squeeze the material flowing into the filter mechanism, and then separate the solid and liquid of the material. The material pressure filtration method based on the structure of the device is fast and efficient, and can greatly improve the production efficiency of solid-liquid separation of materials.

[0030] 1. Overall framework 1

[0031] The overall frame 1 is the basic structure of the device, and is used to fix other components of the device, so that each part of the structure is connected to each other. The overall frame 1 is made of metal material and has a firm structure. The overall frame 1 is fixed with a top pressing part, a filtering mechanism and a bottom supporting part in sequence from top to bottom.

[0032] 2. Filtration mechanism

[0033] The filter me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com