Patents

Literature

35results about How to "Avoid direct extrusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

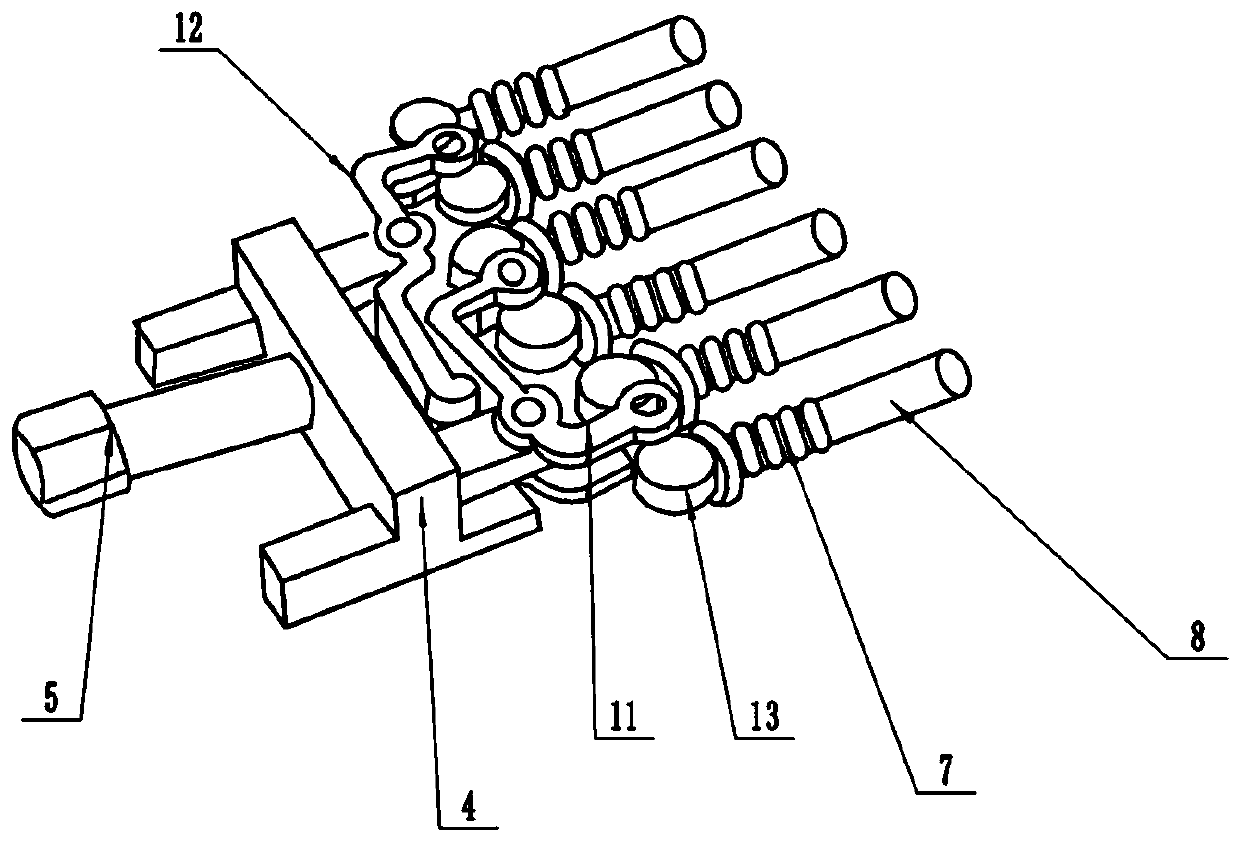

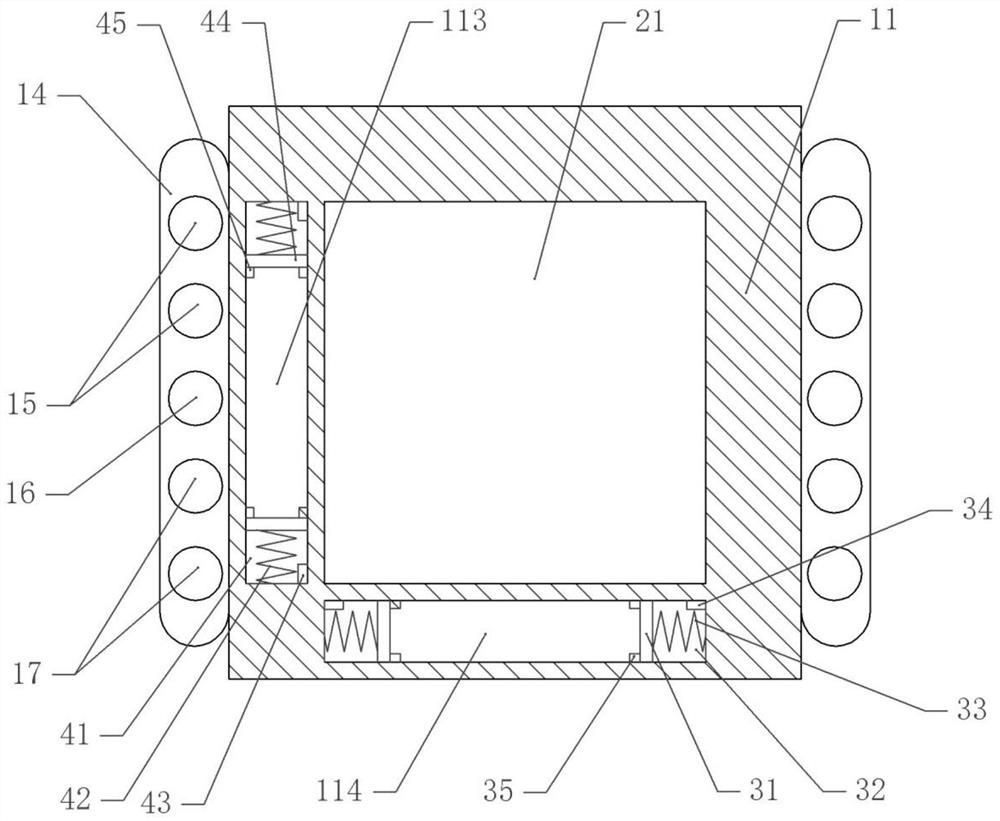

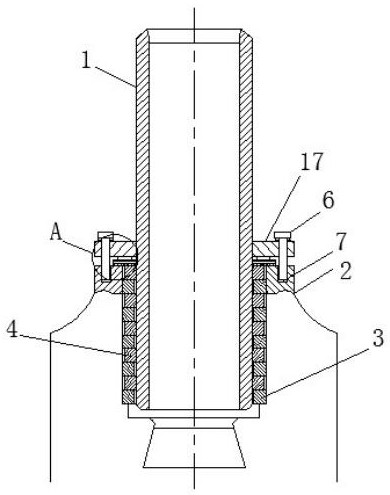

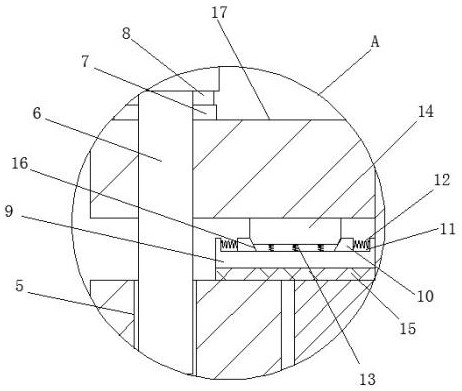

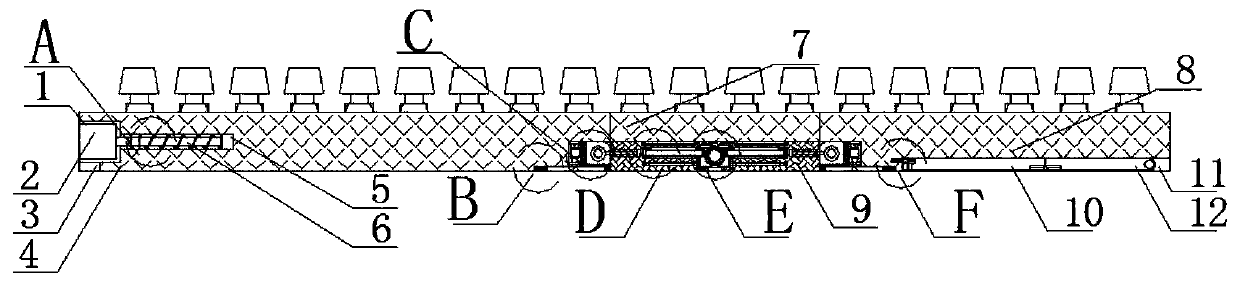

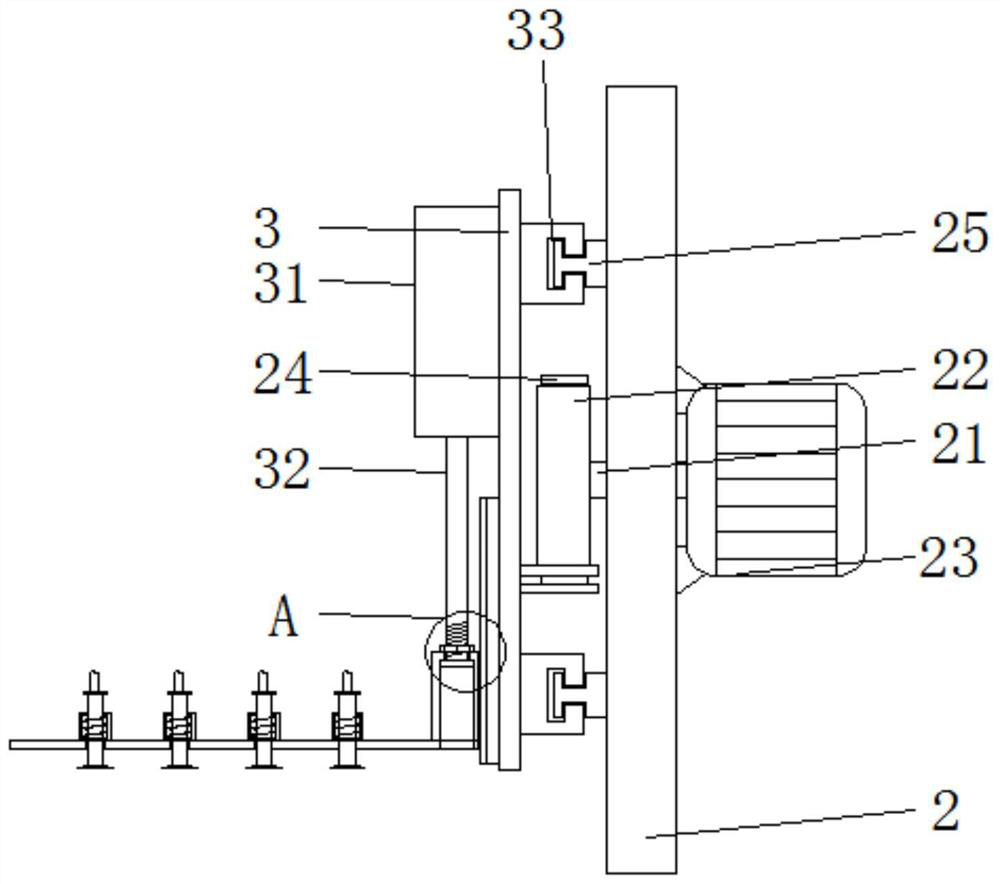

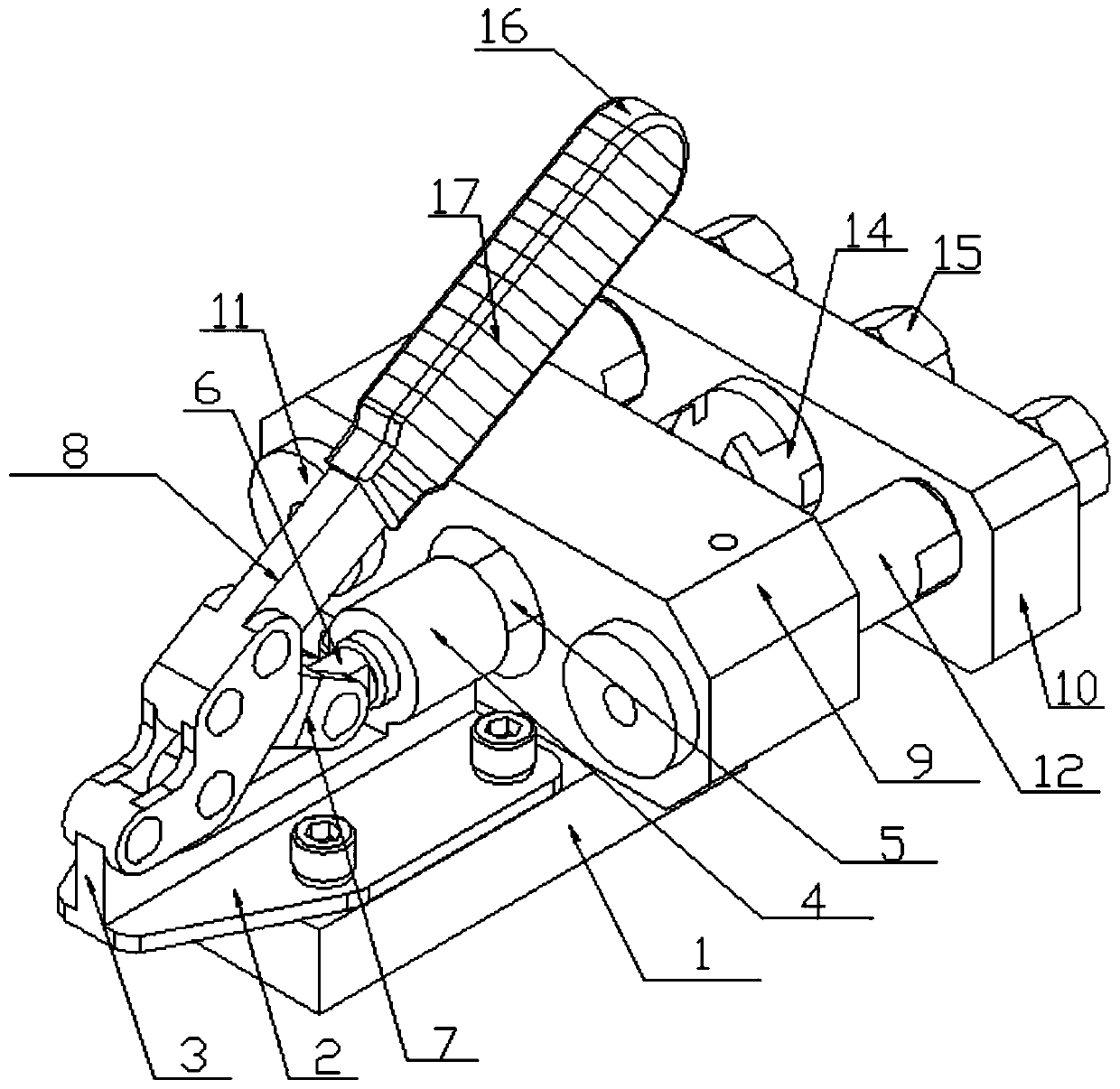

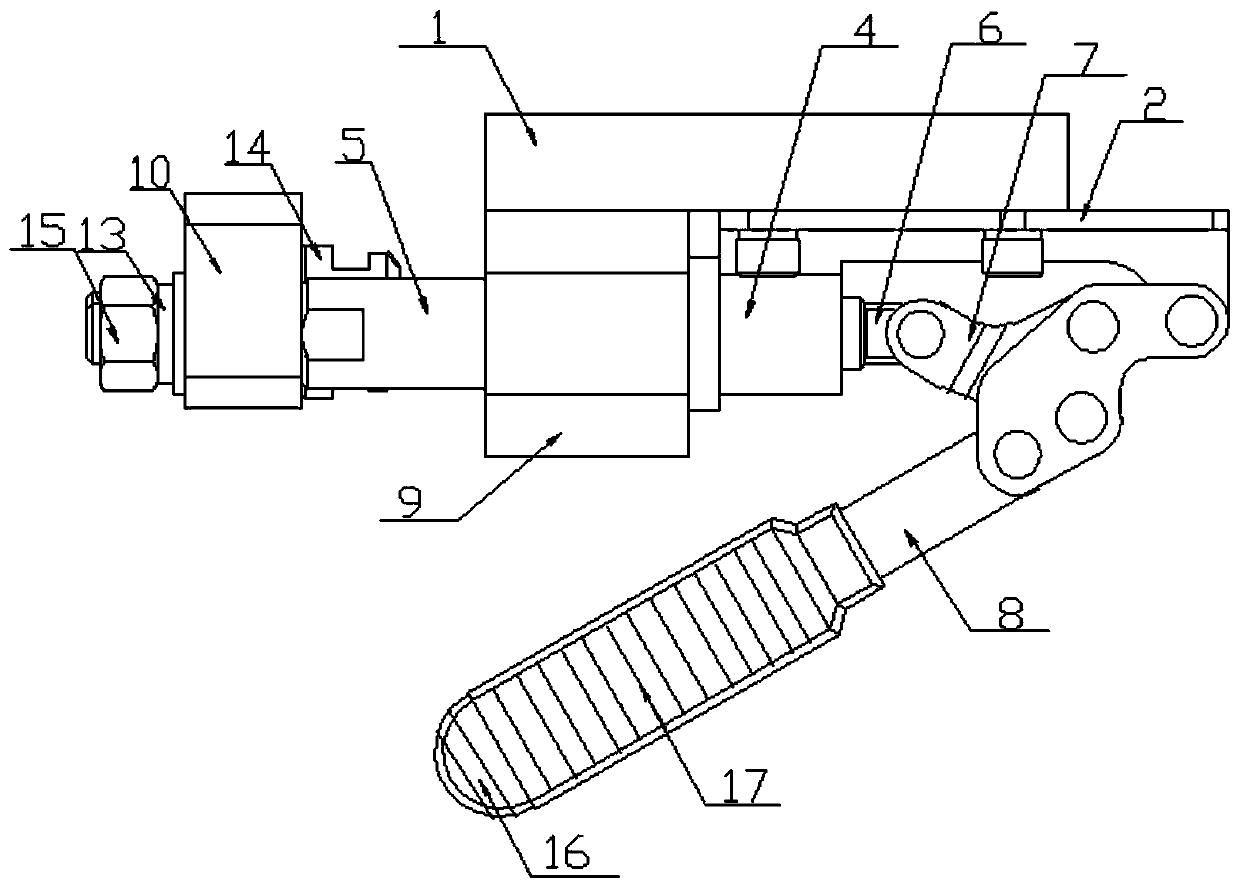

Pipe fitting clamping device for automatic machine

ActiveCN107971795ASolve the problem of poor clamping effectAccurately achieve the processing purposeWork clamping meansPositioning apparatusPipe fittingEngineering

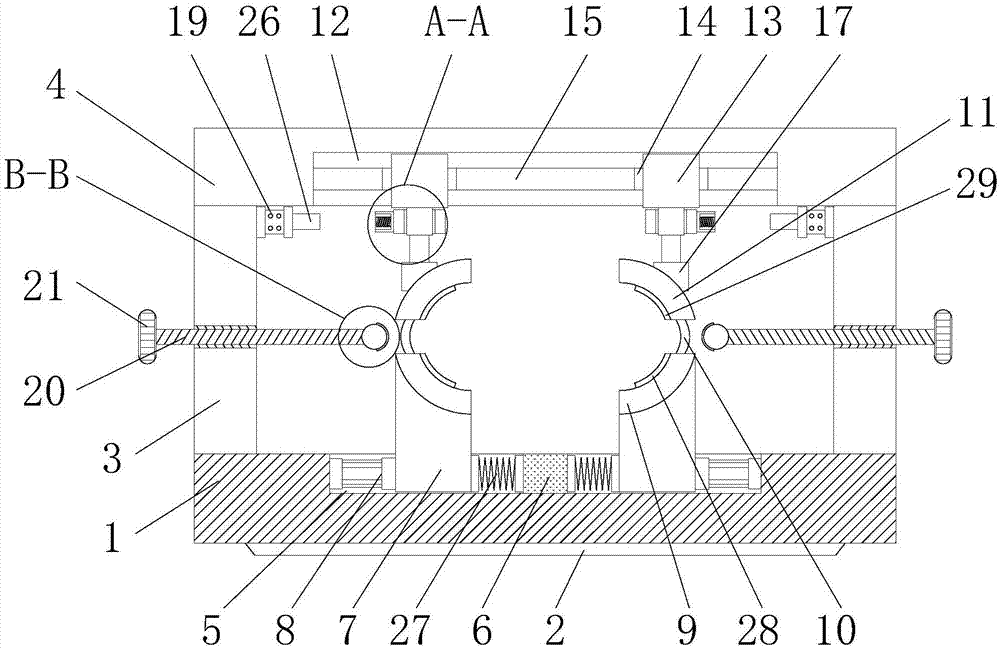

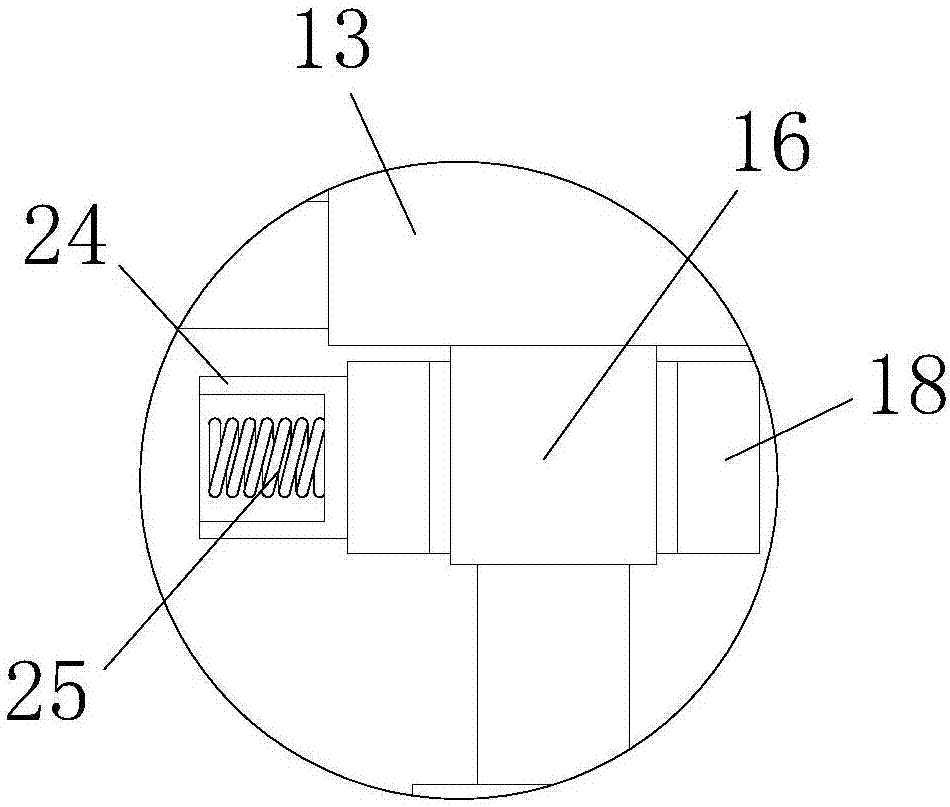

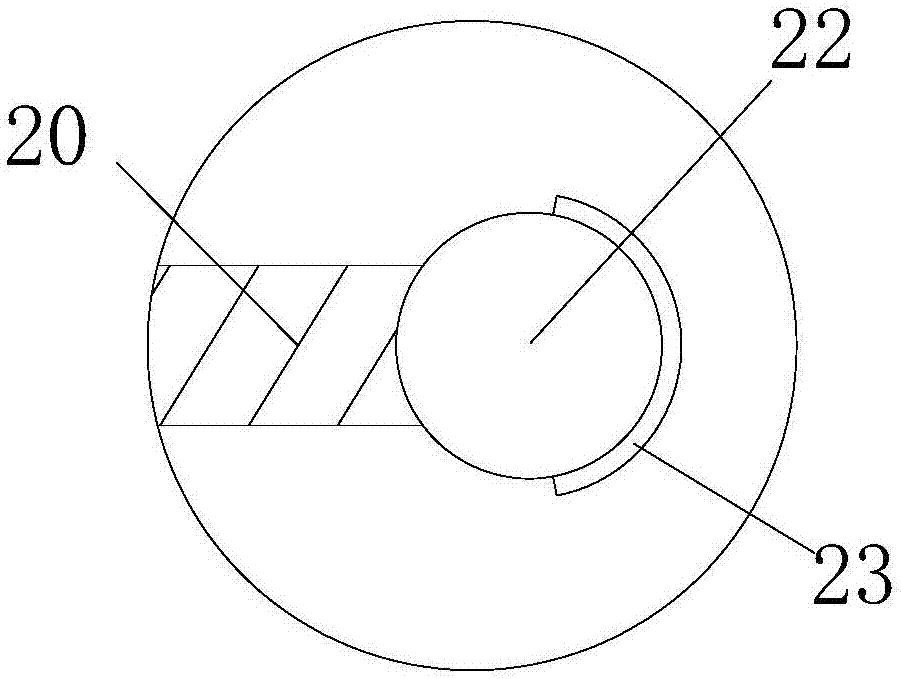

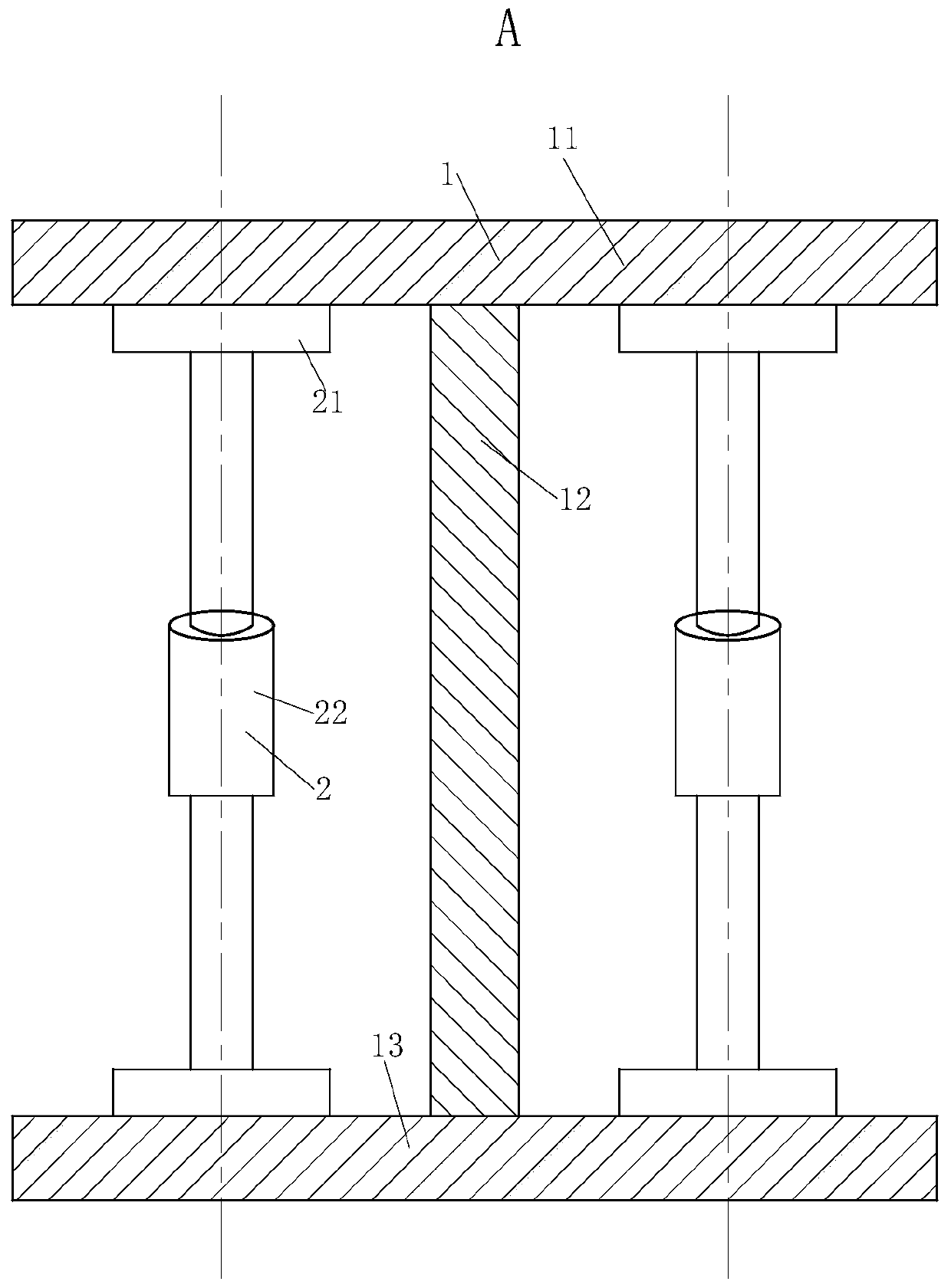

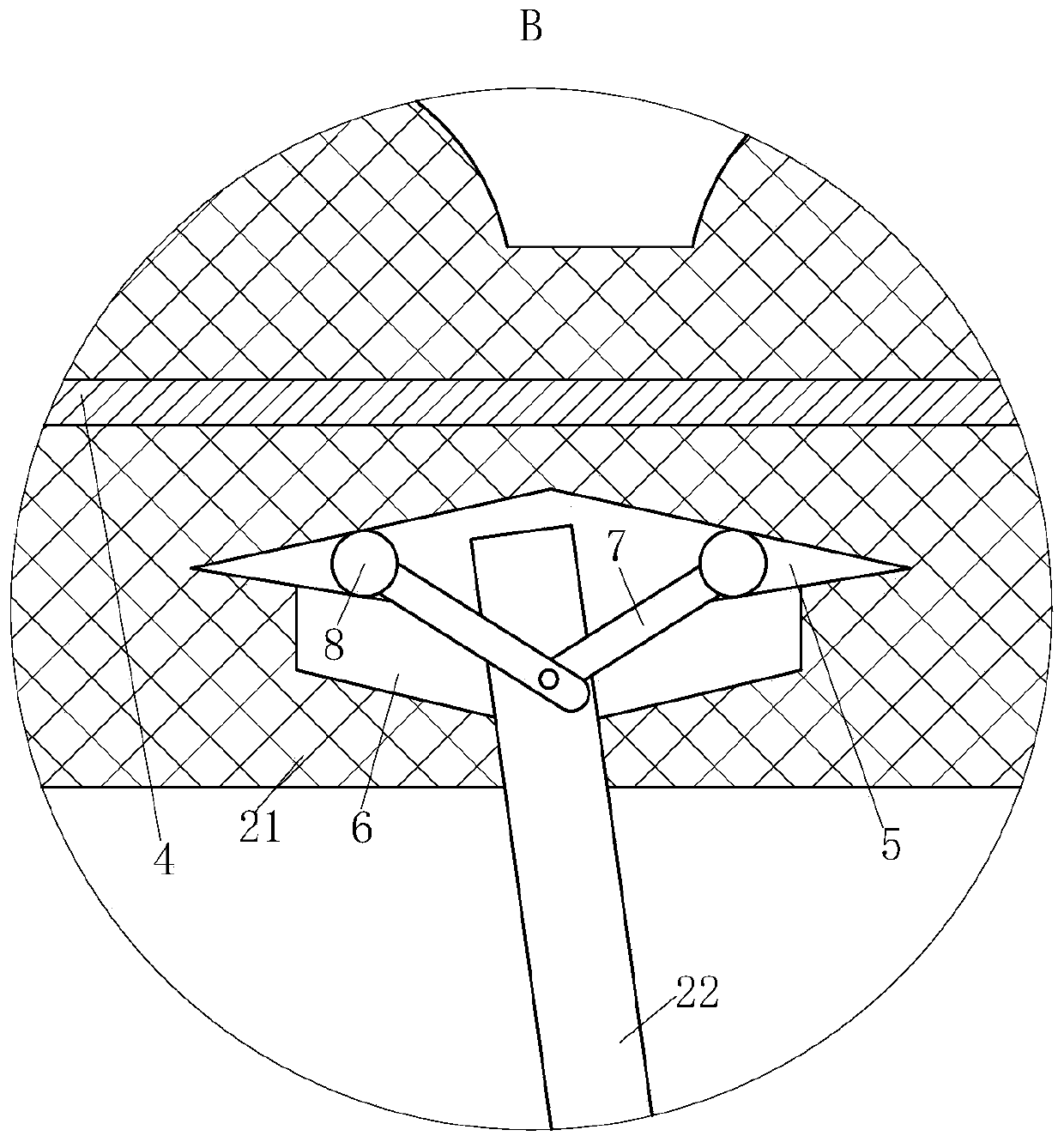

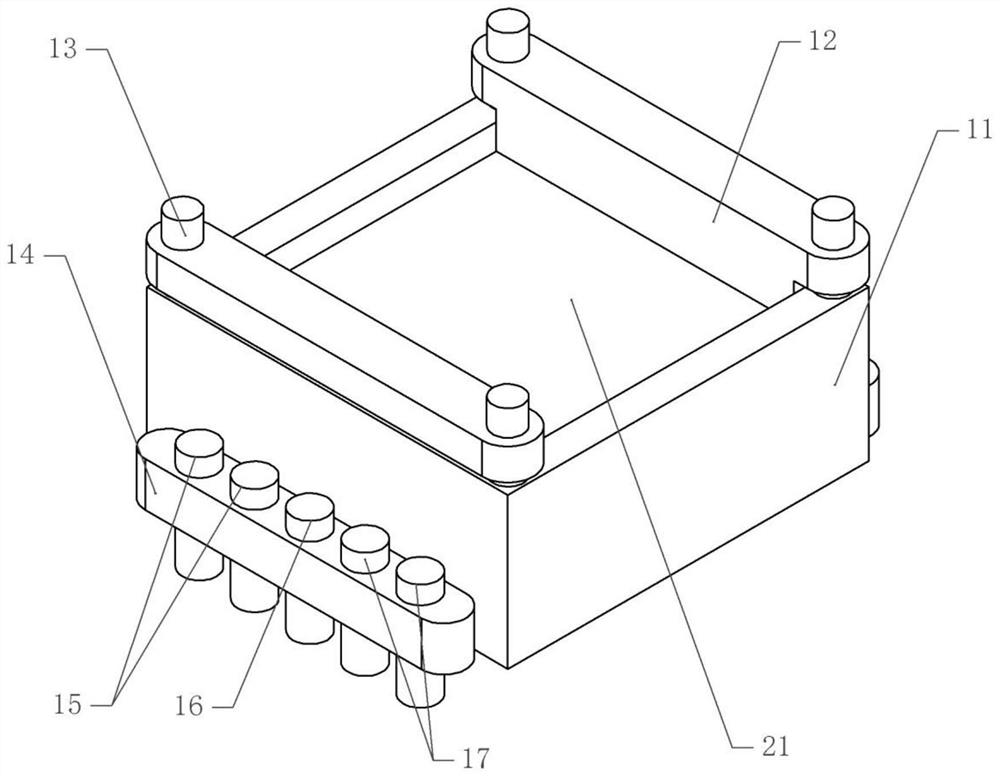

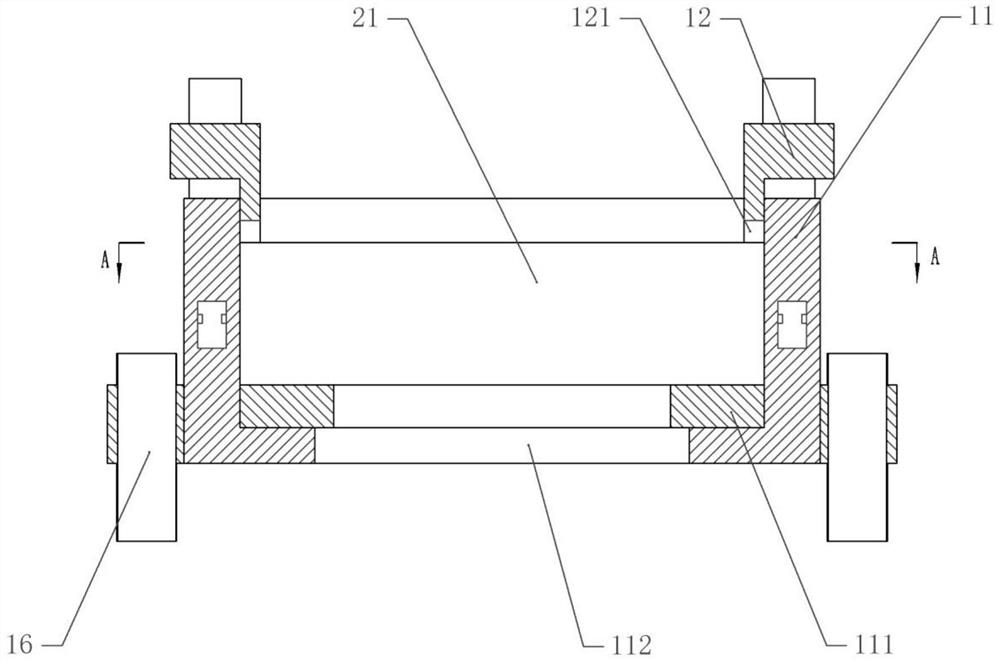

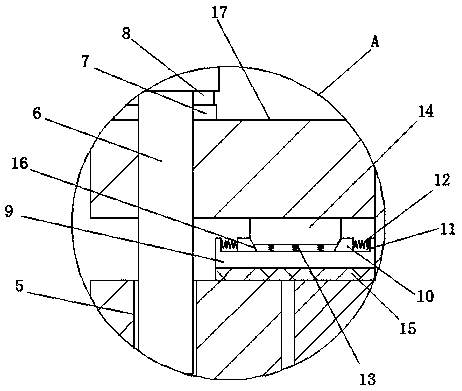

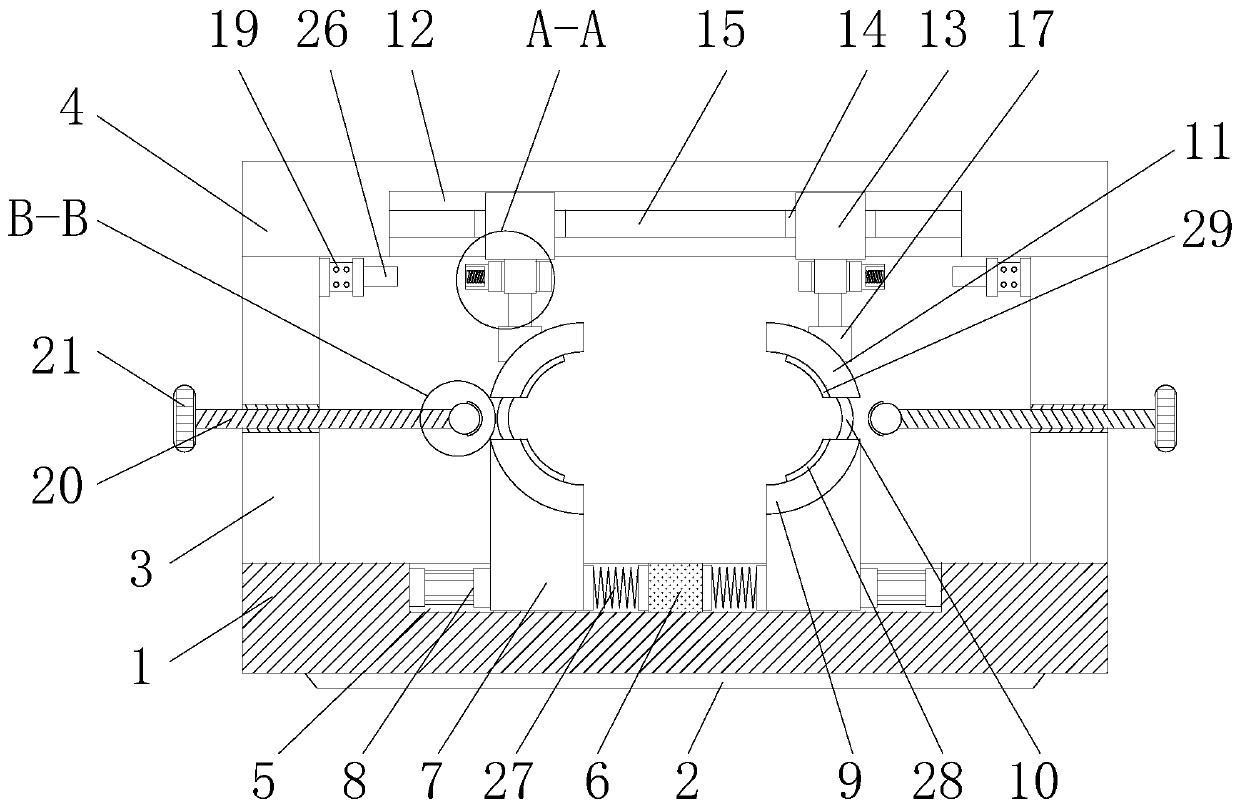

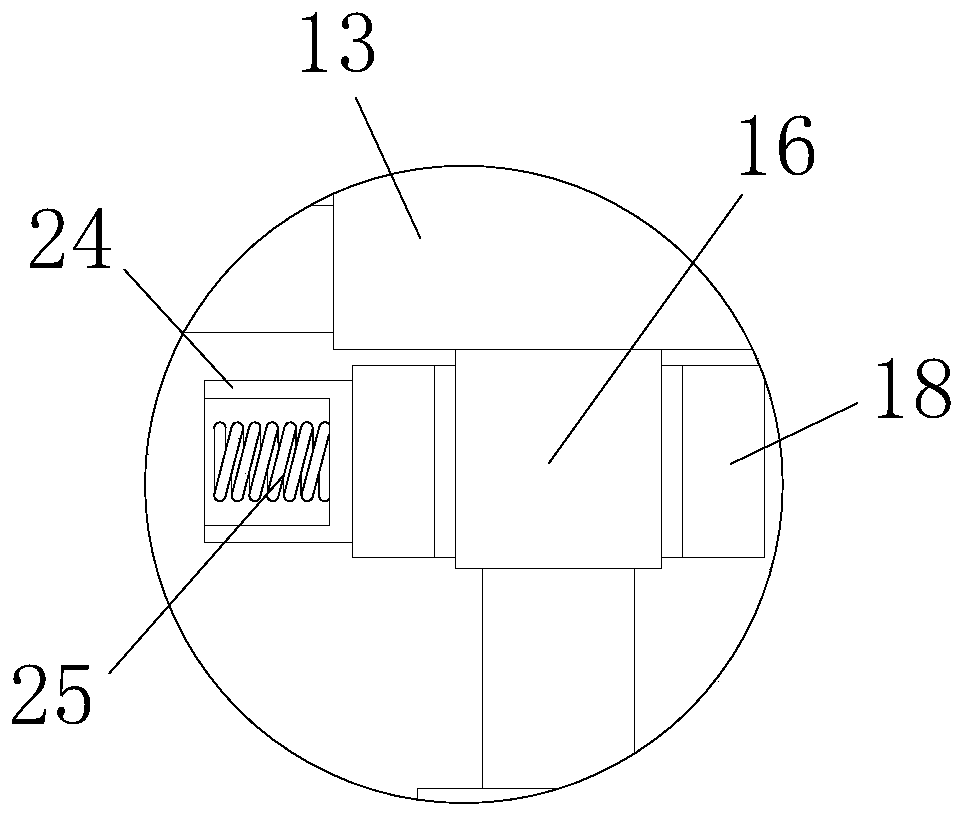

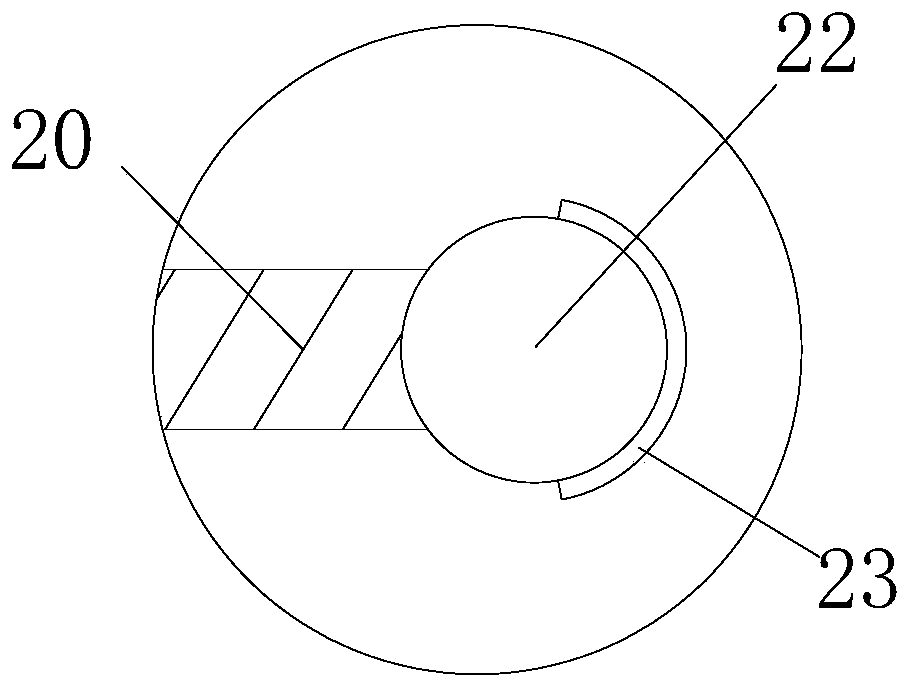

The invention discloses a pipe fitting clamping device for an automatic machine. The pipe fitting clamping device comprises a bottom plate, a sliding rail is arranged at the bottom of the bottom plate, and supporting plates are fixedly connected to the two sides of the top of the bottom plate; and the tops of the two supporting plates are fixedly connected through a top plate, a first sliding groove is formed in the top of the bottom plate, and a fixing block is fixedly connected to the middle point of the bottom of the inner wall of the first sliding groove. According to the pipe fitting clamping device for the automatic machine, a second sliding groove, second sliding blocks, pneumatic telescopic rods, abutting blocks, annular sleeves and second air cylinders are arranged, and the problem that the clamping effect of a common pipe fitting clamping device is not good is solved, so that the stress at each part of the pipe fitting can be reasonably distributed; and when the pipe fittingis machined, shaking of the pipe fitting caused by unstable fixing due to the fact that the tensioning force in one part of the fitting is too large or too small does not occur, so that the expected machining purpose is achieved accurately, the clamping radius is conveniently adjusted according to the diameter of a pipe, and great convenience is brought to a user.

Owner:安徽新立滤清器有限公司

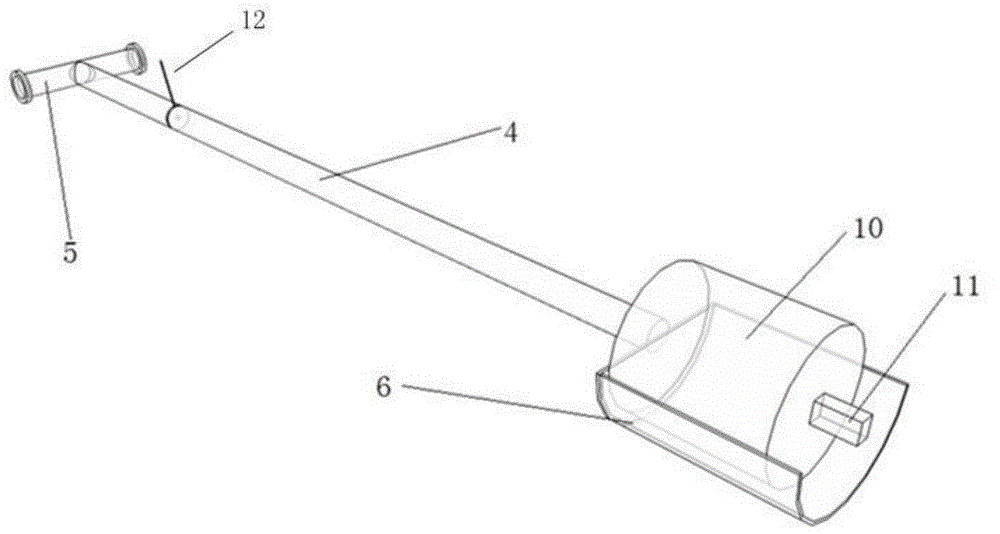

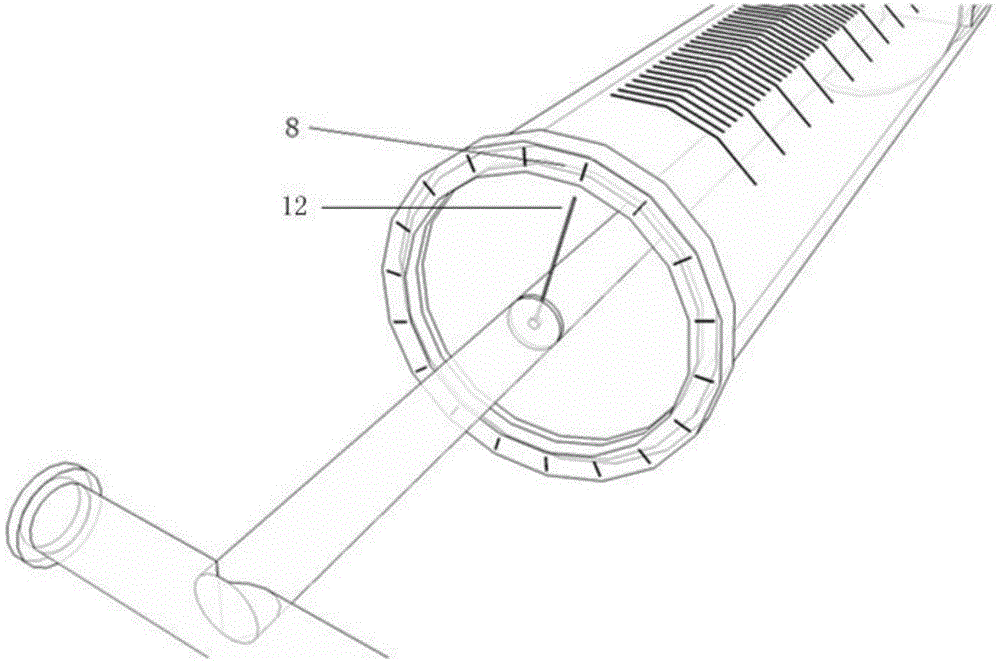

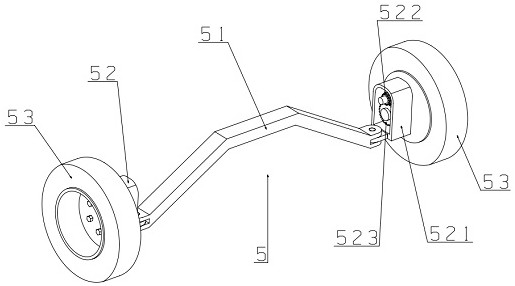

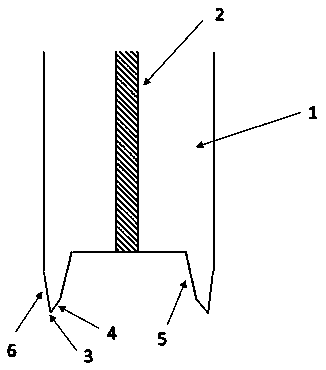

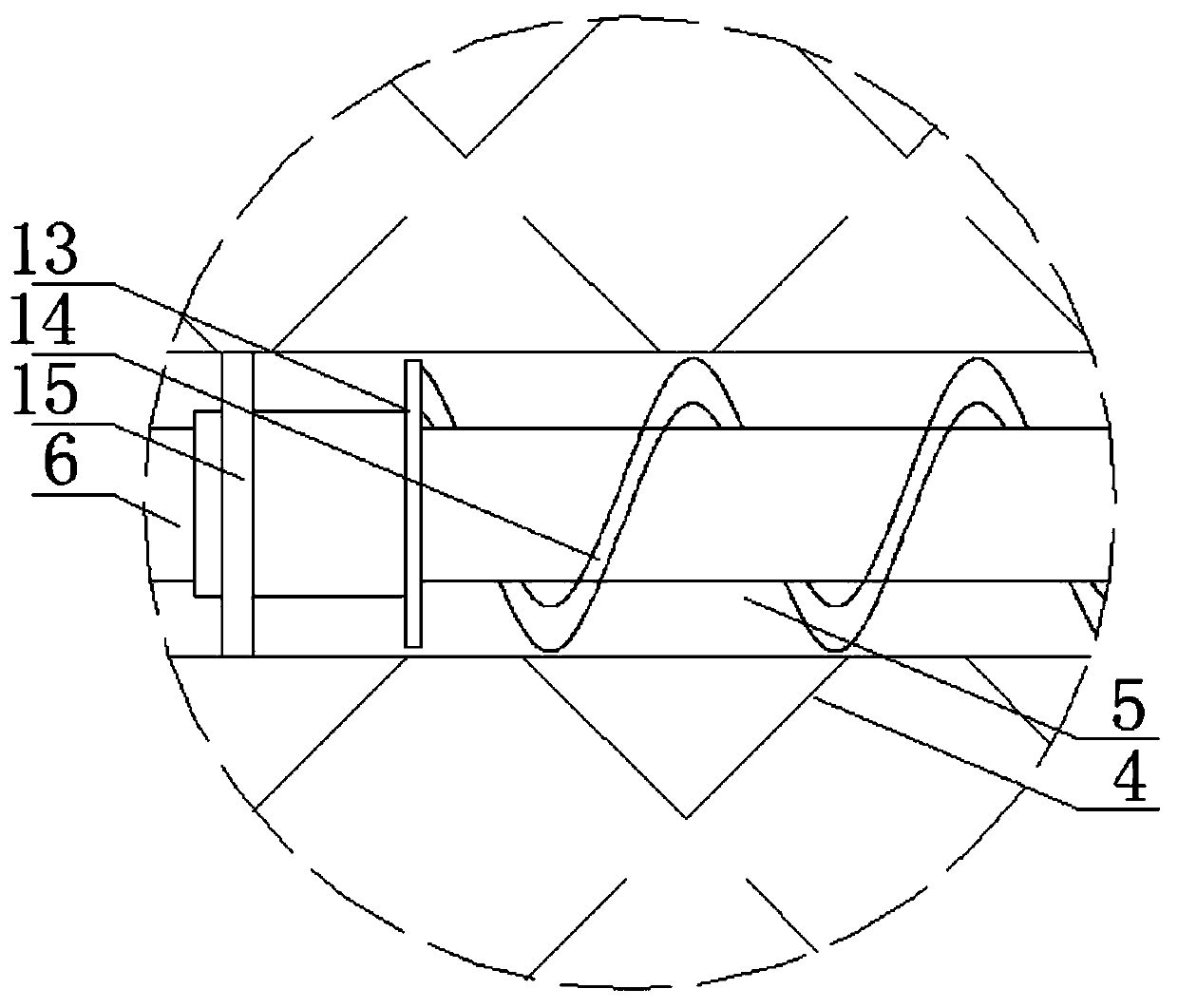

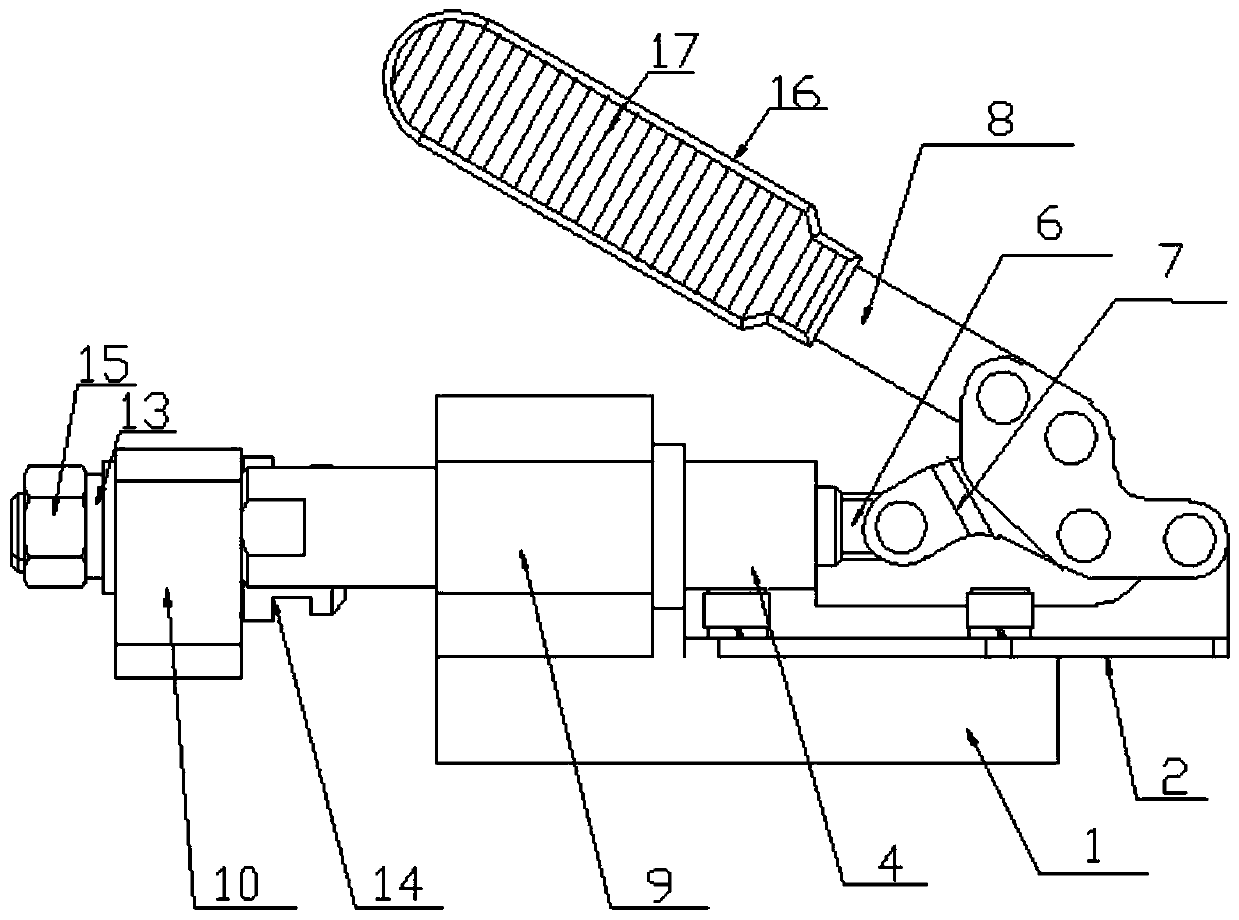

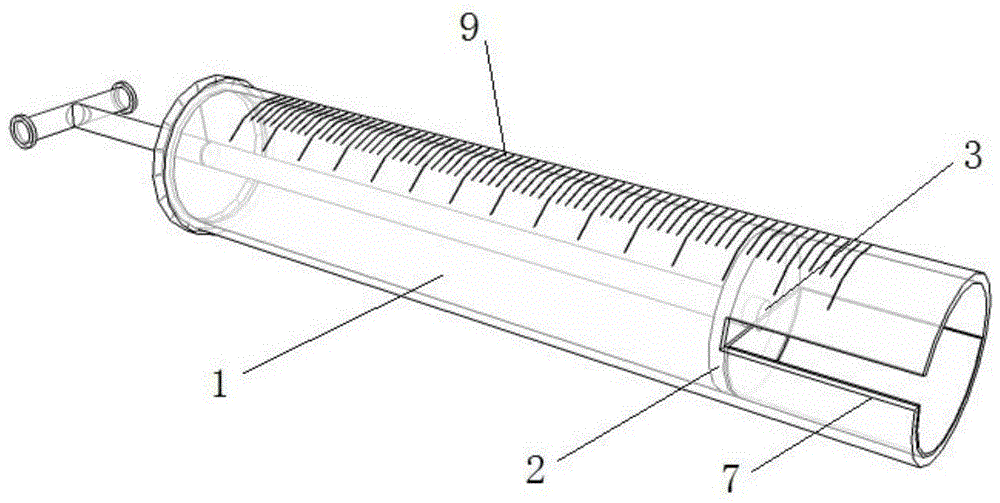

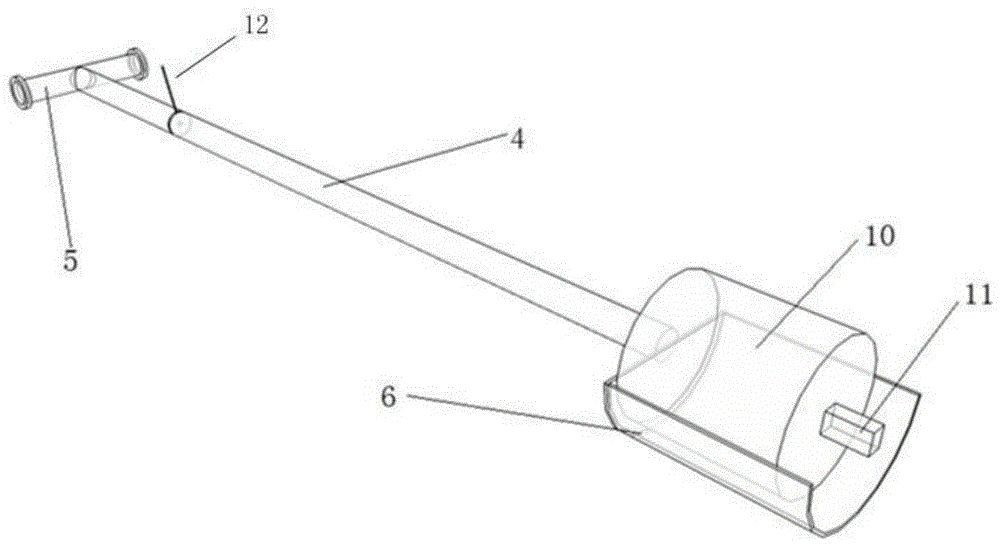

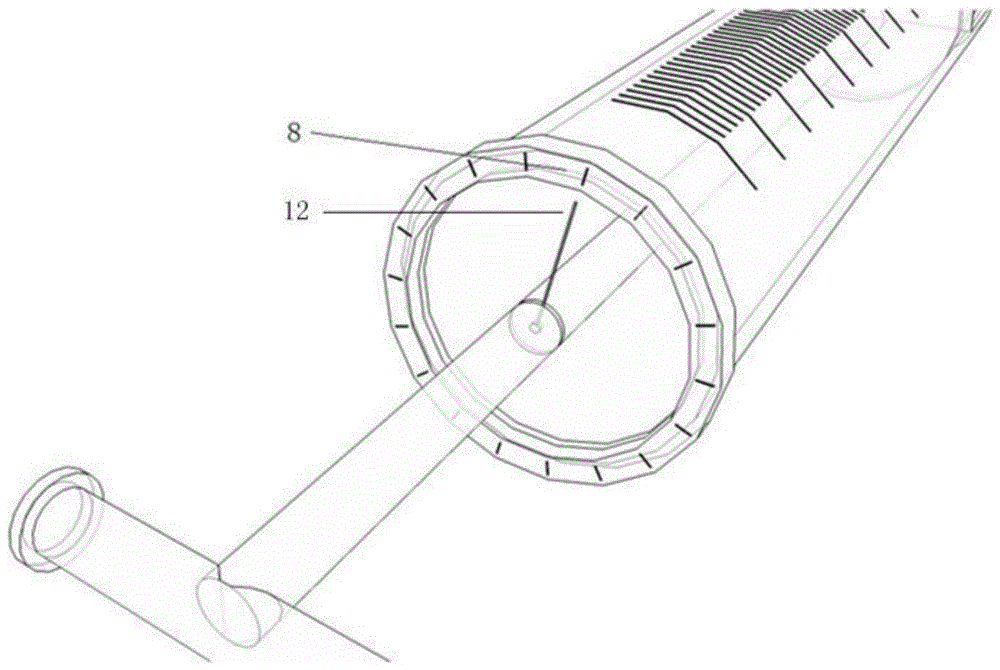

Placing device for TSP blast hole emulsion explosive and operation method

ActiveCN104613834AIncrease success rateImprove placement efficiencyBlastingDetonatorMeasurement device

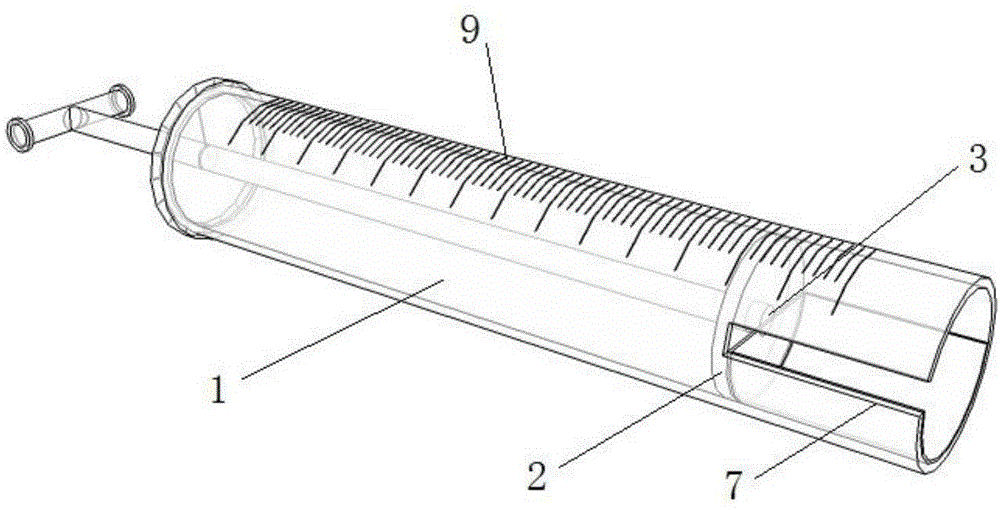

The invention relates to a placing device for a TSP blast hole emulsion explosive and an operation method. The placing device comprises a stainless steel protective sleeve, an in-sleeve separation sheet is fixed to the interior of the stainless steel protective sleeve, a sleeve open slot is formed in the front end of the stainless steel protective sleeve, a separation sheet hole is formed in the in-sleeve separation sheet so that a sleeve core connecting rod can penetrate, the two ends of the sleeve core connecting rod are connected with an explosive placing hopper and a rotary handle, and the sleeve core connecting rod, the explosive placing hopper and the rotary handle are fixedly connected into a whole. The depth of the portion, entering a blast hole, of the sleeve core connecting rod can be adjusted through extraction according to measurement of a dividing rule and the rotation angle of the rotary handle can be acquired through an angle measurement device. By the adoption of the novel placing device for the TSP blast hole emulsion explosive and the operation method, the emulsion explosive and an electronic detonator exploder can not be affected by slurry and gravel hole blockage under the protection of the rigid sleeve, and the success rate of TSP blast hole detonation is increased; meanwhile, the device is simple in structure and convenient to operate, the explosive can be transported to the position of the preset depth of the blast hole only by extracting and rotating the sleeve core connecting rod and placing efficiency of the TSP blast hole emulsion explosive can be greatly improved.

Owner:SHANDONG UNIV

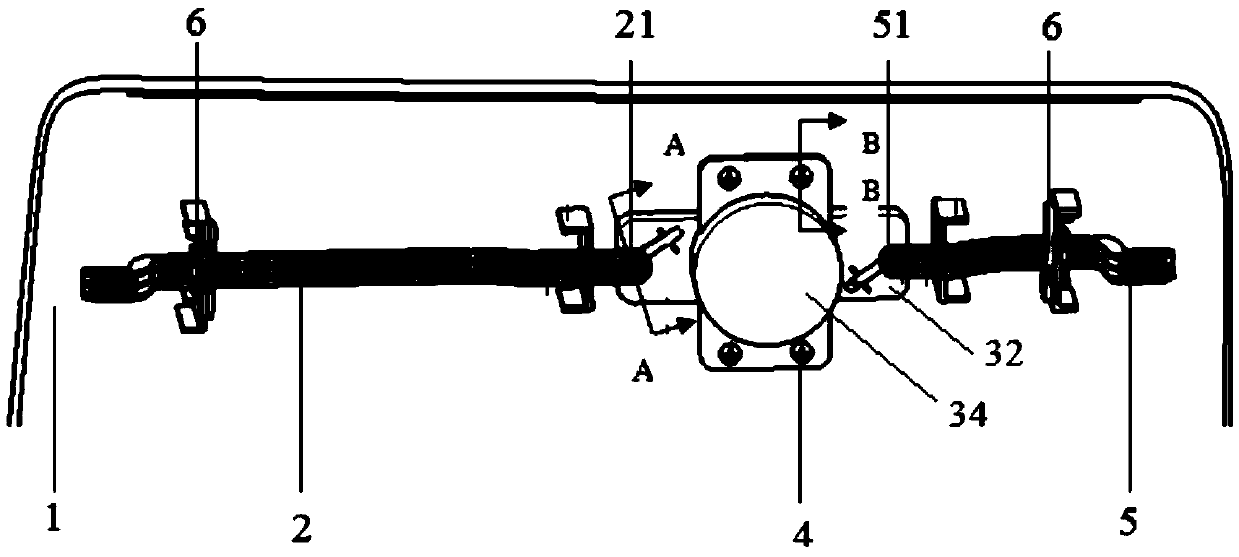

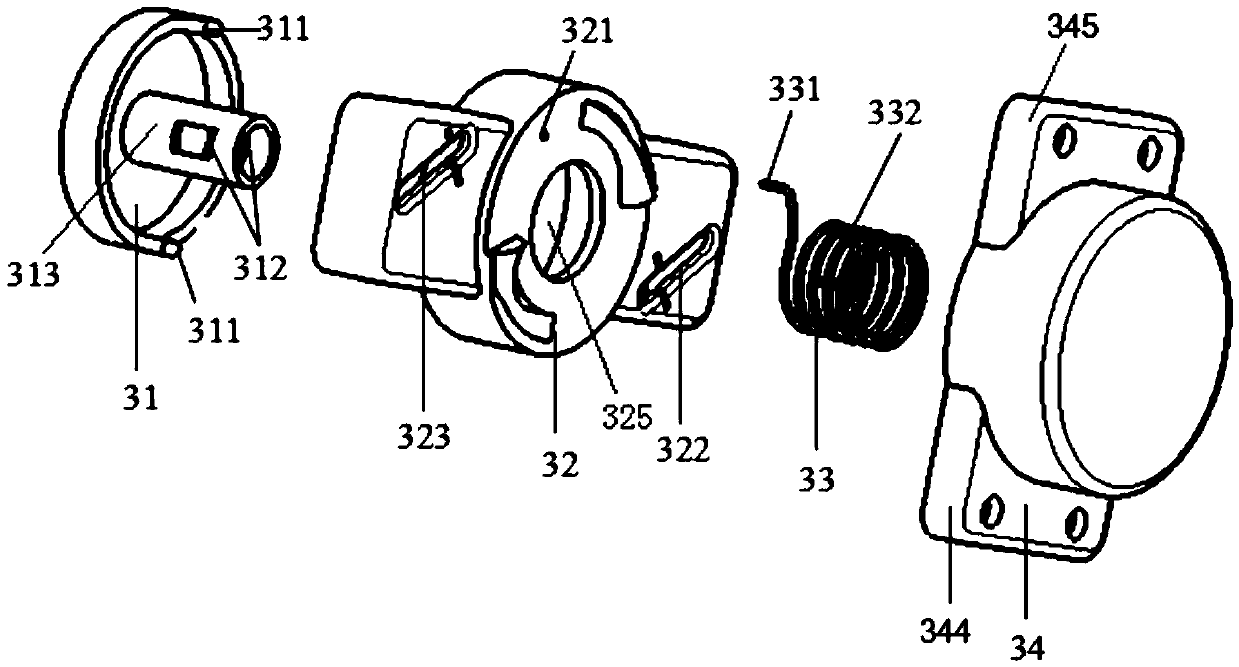

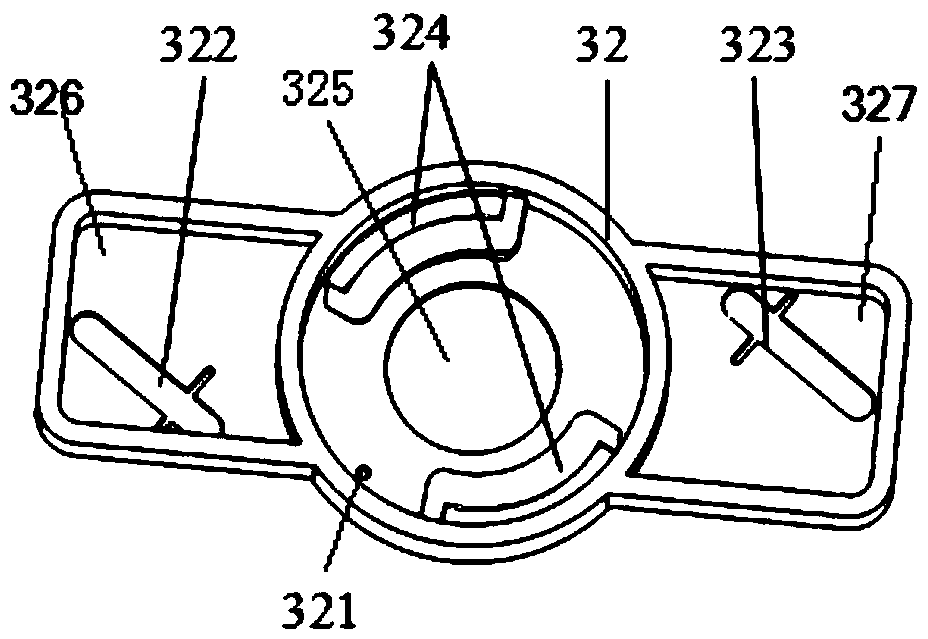

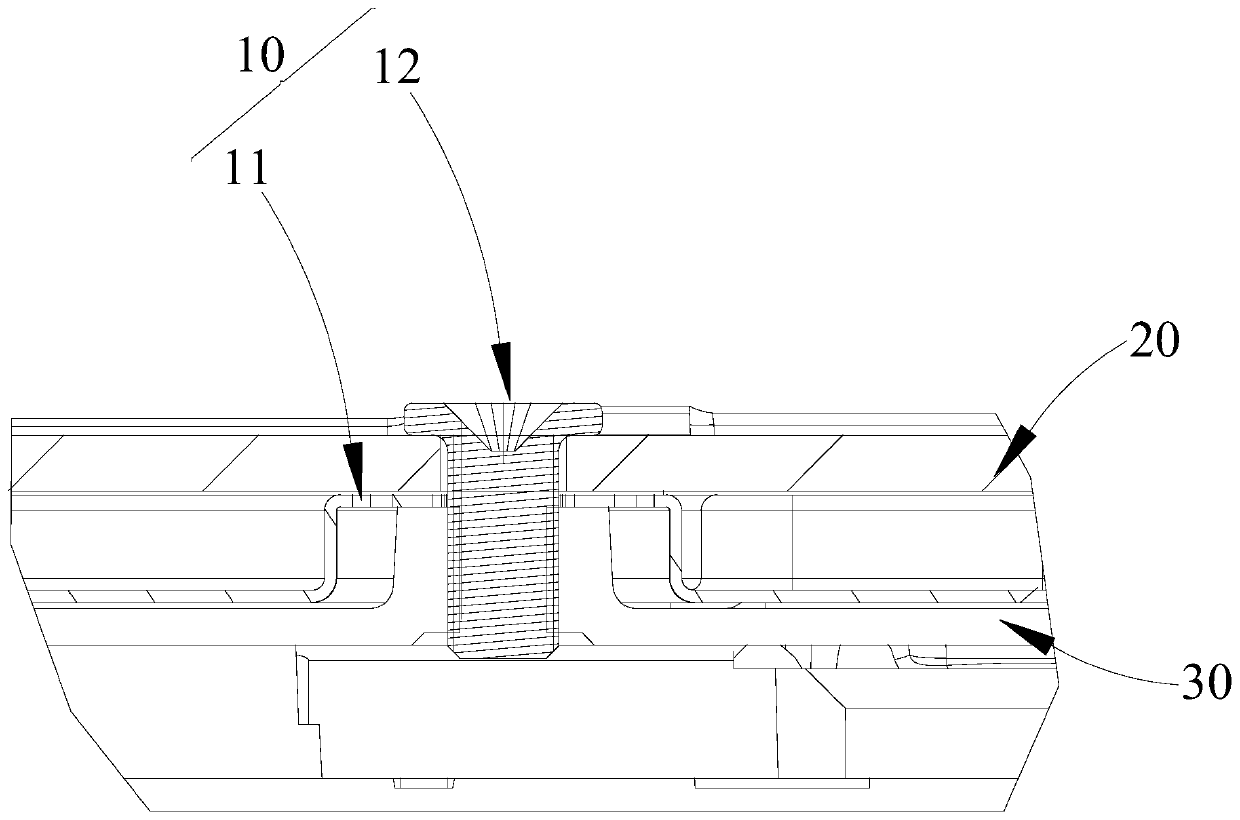

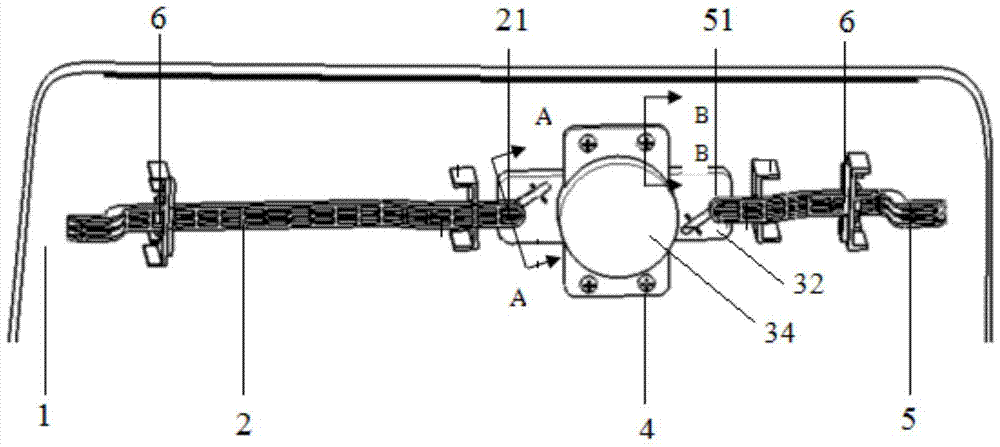

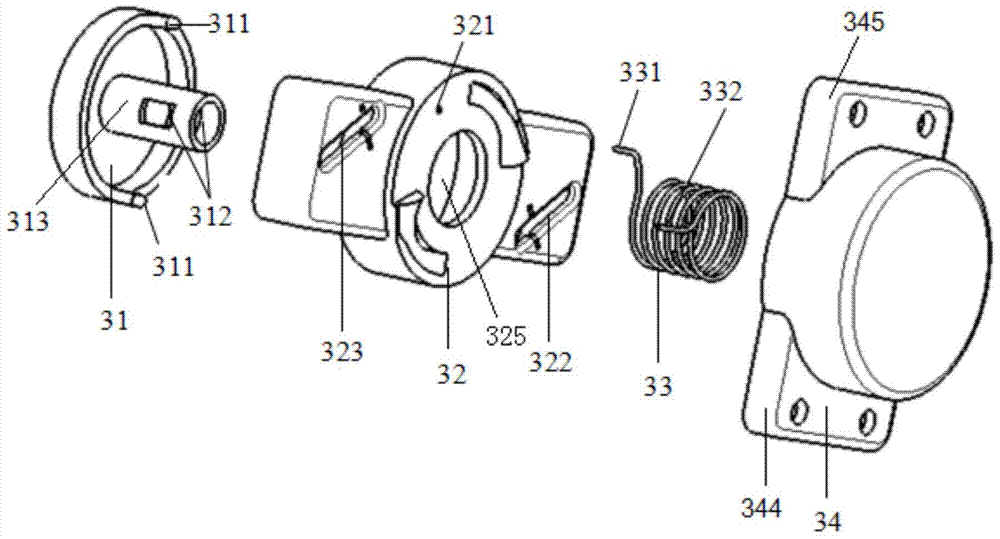

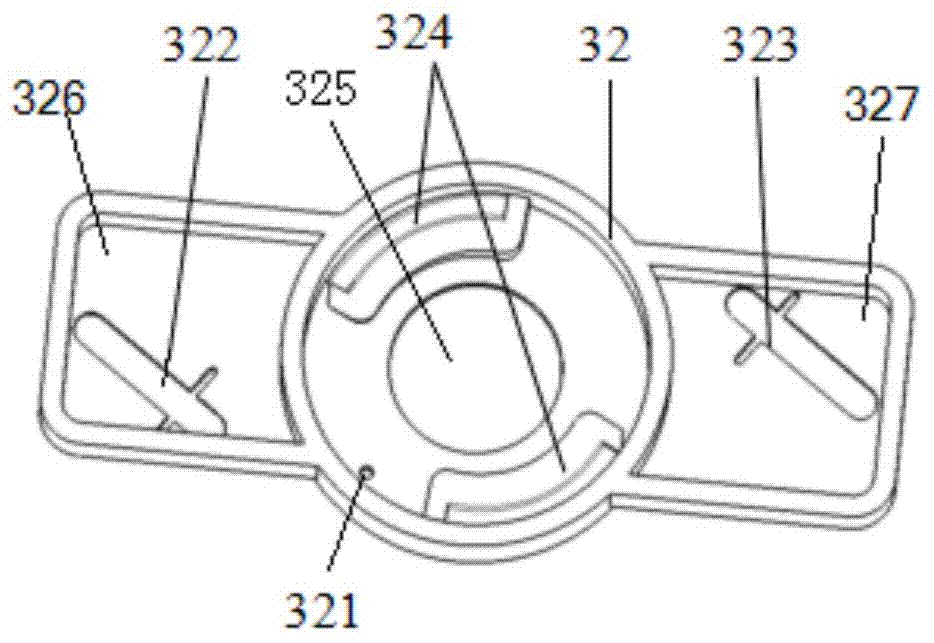

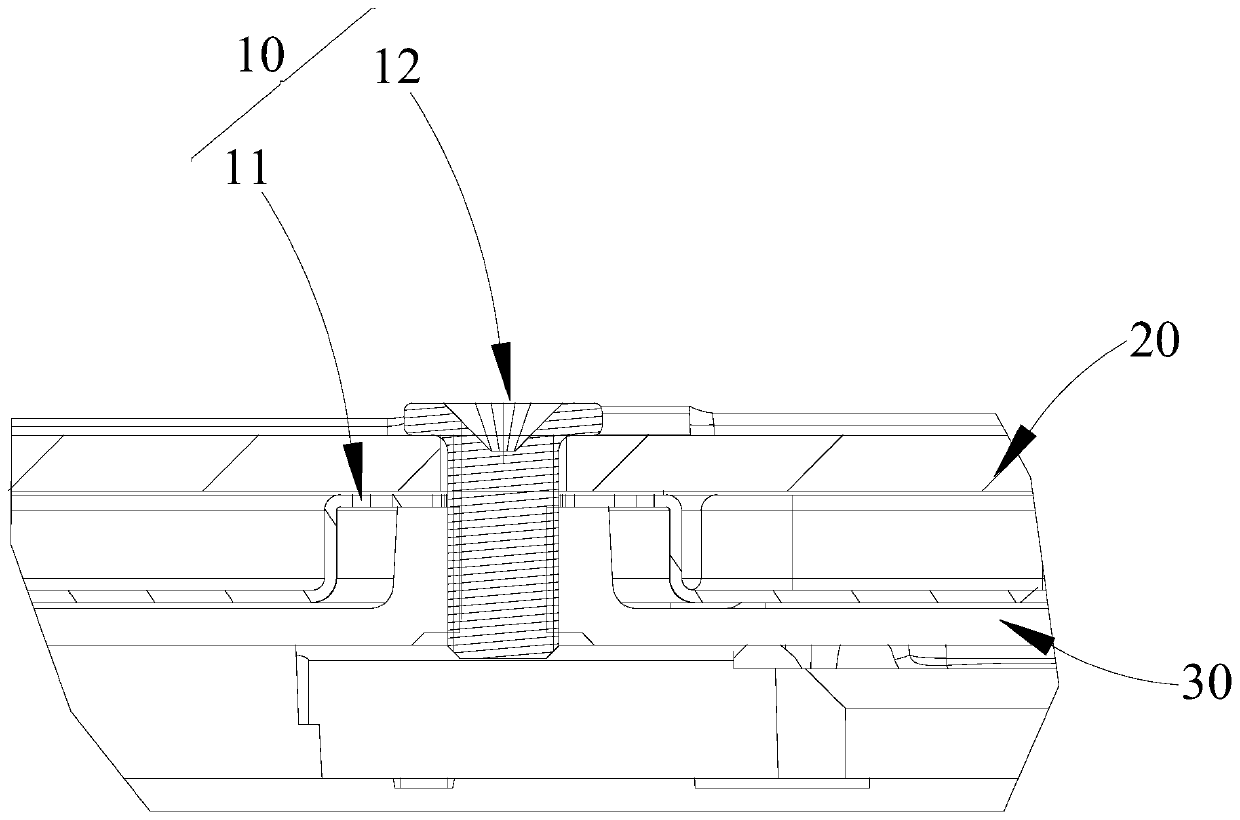

Button-type glove-box lock structure

ActiveCN105370115ASimple structureLow costNoise-prevention/anti-rattling lockingLinear motionEngineering

The invention relates to a button-type glove-box lock structure which comprises a left lock rod, a right lock rod and lock rod sleeves fixed on an outer glove-box plate and further comprises a button, wherein a transmission mechanism is connected between the left lock rod and the right lock rod; the button is provided with a cover-like casing; the closed end of the cover-like casing faces the outside; the cover-like casing is provided with a first connecting column and protruding columns, which face the inside; and the transmission mechanism comprises a transmission piece, a lock seat and an elastic piece used for connecting the transmission piece and the lock seat. According to the lock structure adopting the scheme, a glove box can be opened by pressing the button; the protruding columns are arranged on the button, circular arc-shaped grooves corresponding to the protruding columns are formed in the transmission piece, and the bottom surfaces of the circular arc-shaped grooves are wedge surfaces, so that the linear motion of the button is converted into the rotary motion of the transmission piece through the relative motion of the protruding columns on the wedge surfaces; and the transmission piece rotates to drive the left lock rod and the right lock rod to do axial linear motion to open the glove box. The scheme solves the problem that the conventional lock structure is complex in structure and inconvenient to operate.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

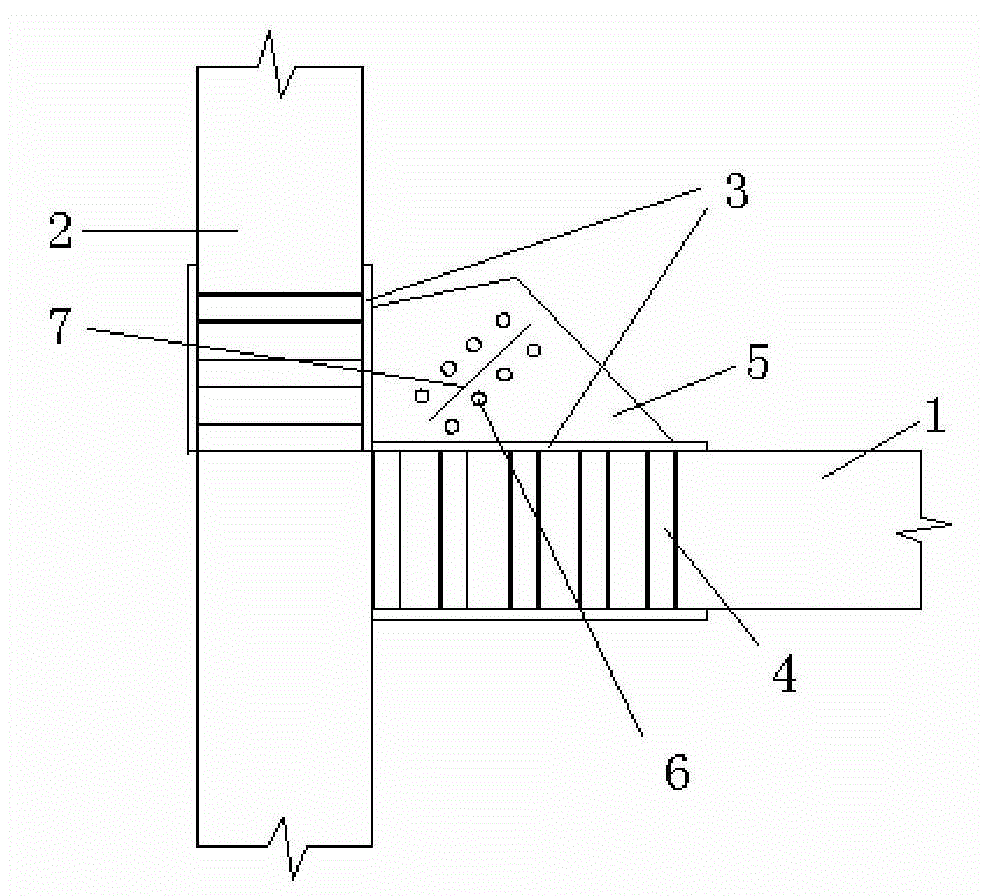

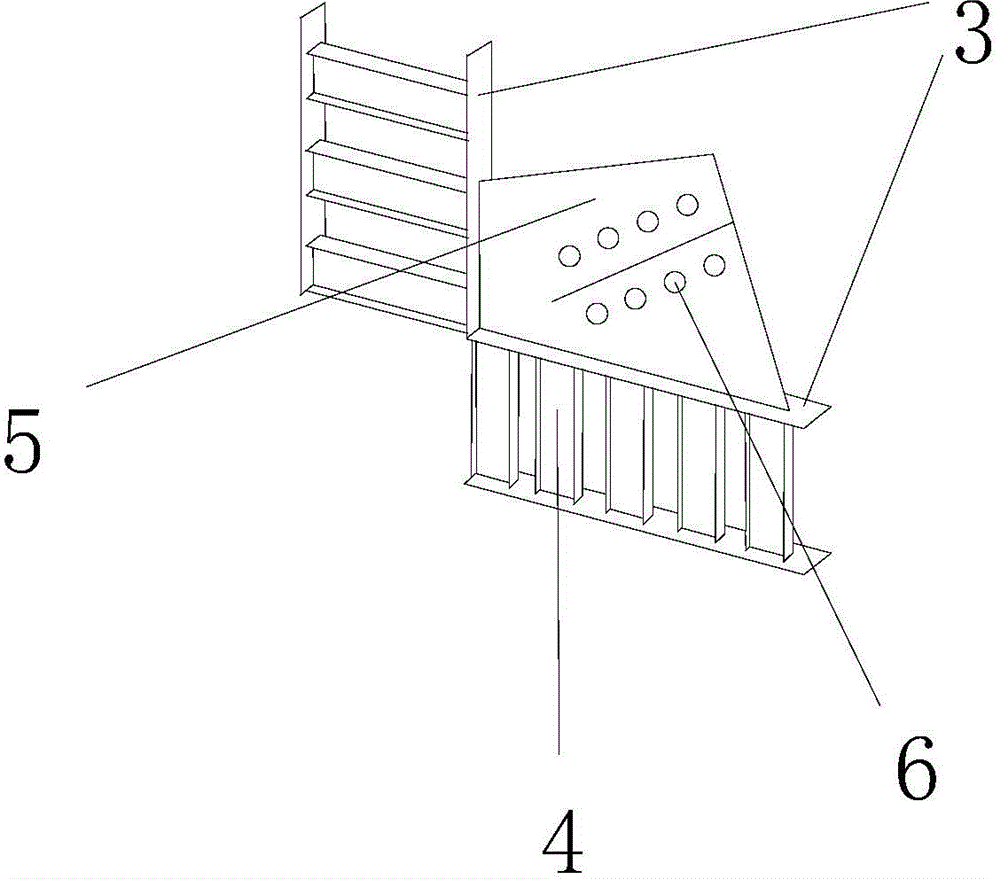

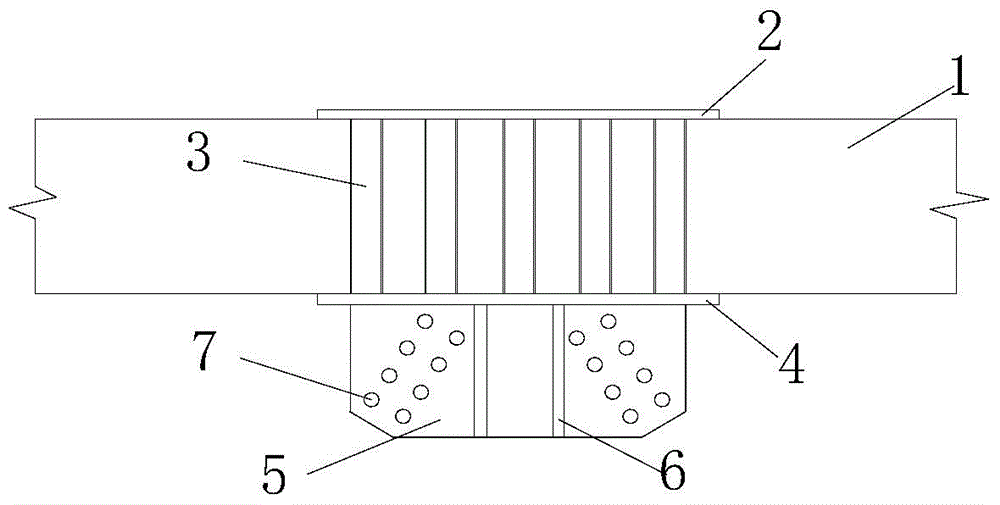

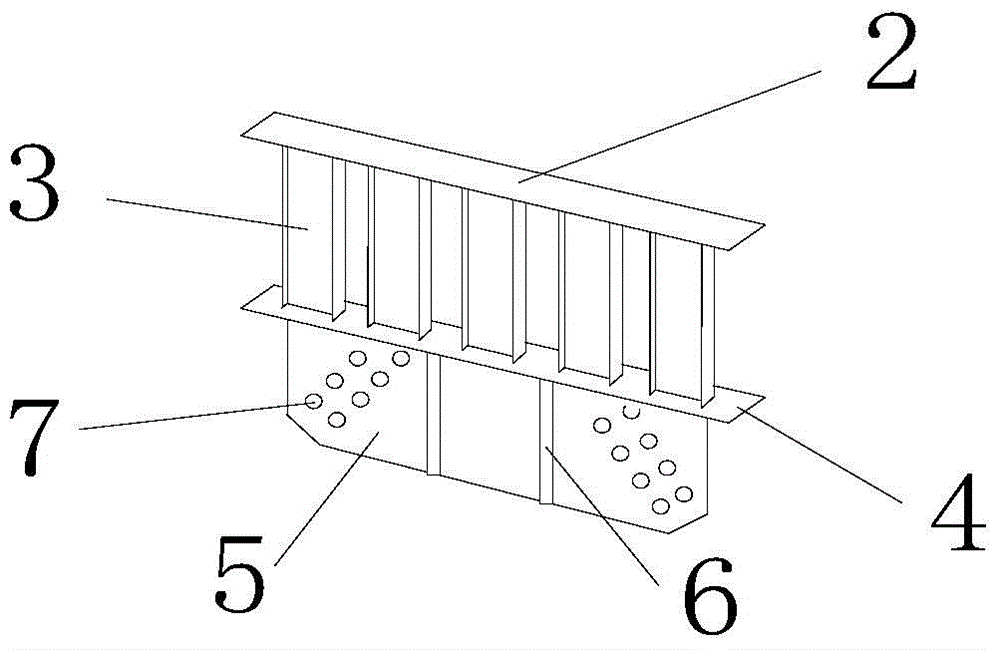

Joint for connecting buckling-restrained brace, concrete beam and concrete column

InactiveCN104563304AImprove stabilityIncrease stiffnessShock proofingStress concentrationBuckling-restrained brace

The invention discloses a joint for connecting a buckling-restrained brace, a concrete beam and a concrete column; an anchoring part anchored in the concrete beam and the concrete column is composed of two groups of spaced H-shaped profile steels; the H-shaped profile steels and an anchoring plate are welded into a whole one; the internal edge of the anchoring plate id arranged at the external sides of the concrete beam and the concrete column; a joint plate is integrally welded with the anchoring plate; the external end of the anchoring plate integrally welded with the joint plate is lengthened to be longer than the lateral side of the joint plate; and bolt holes for fixing the buckling-restrained brace are formed on the joint plate. The H-shaped profile steels in the joint plate have good stability in a plane and high rigidness and are not easy in instability; the profile steels have big welded areas with the anchoring plate and are not easy to produce pulling / pushing damage; the profile steels have big contact and load-transfer areas with the concrete and are capable of uniformly dispersing the load to the concrete beam; the lengthened parts at two ends of the anchoring plate are capable of effectively avoiding direct extrusion between the joint plate and the concrete, so that the stress concentration is relieved and the service life of the joint is prolonged; the integrality of the concrete beam and the concrete column is not influenced, so that hoops and longitudinal ribs in the concrete beam can be arranged easily; the steel ratio in the joint area of the beam and the column is increased and the strength and rigidness of the joint is improved by the plastic deformation of the beam restrained by the anchoring plate; the whole component can be manufactured in a factory and the construction time is saved.

Owner:SHENYANG JIANZHU UNIVERSITY

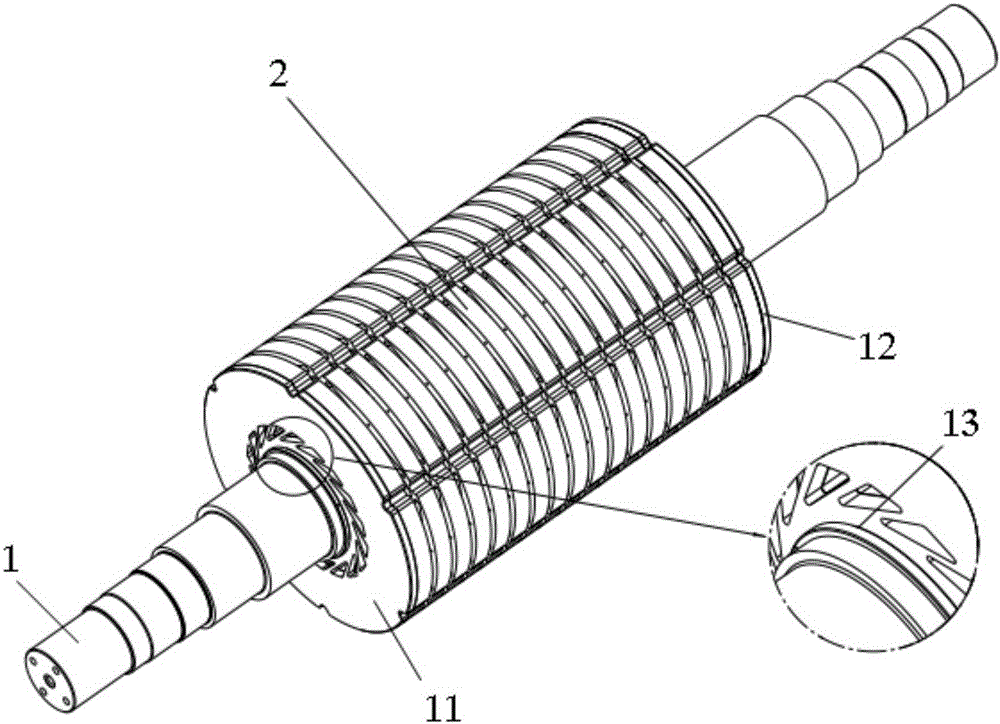

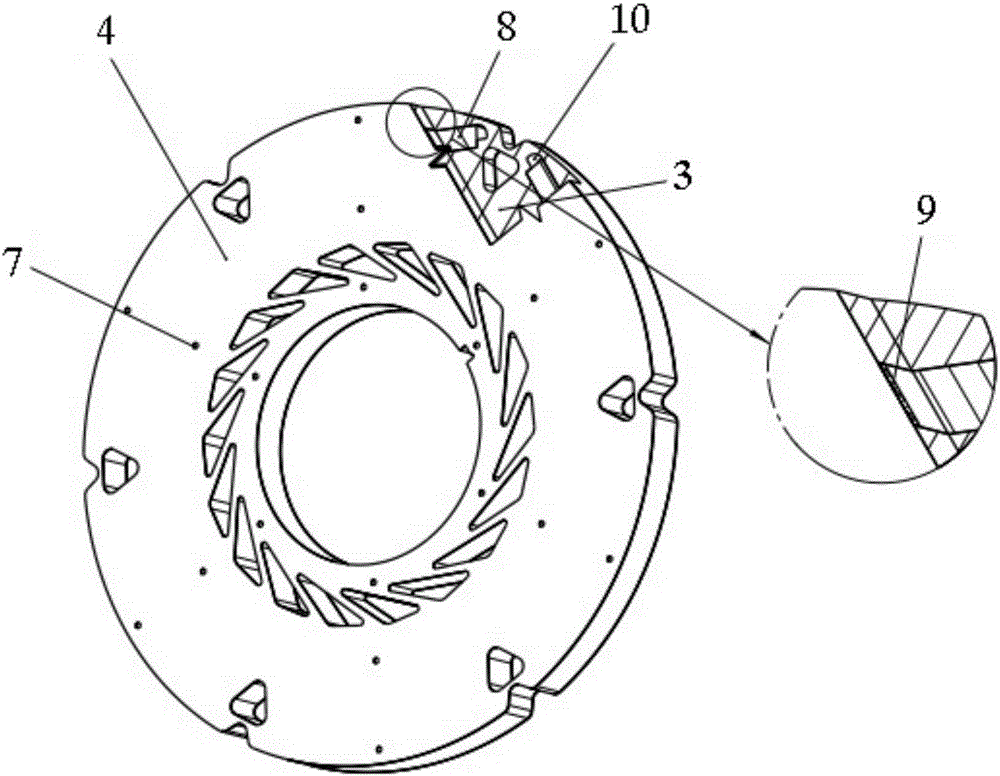

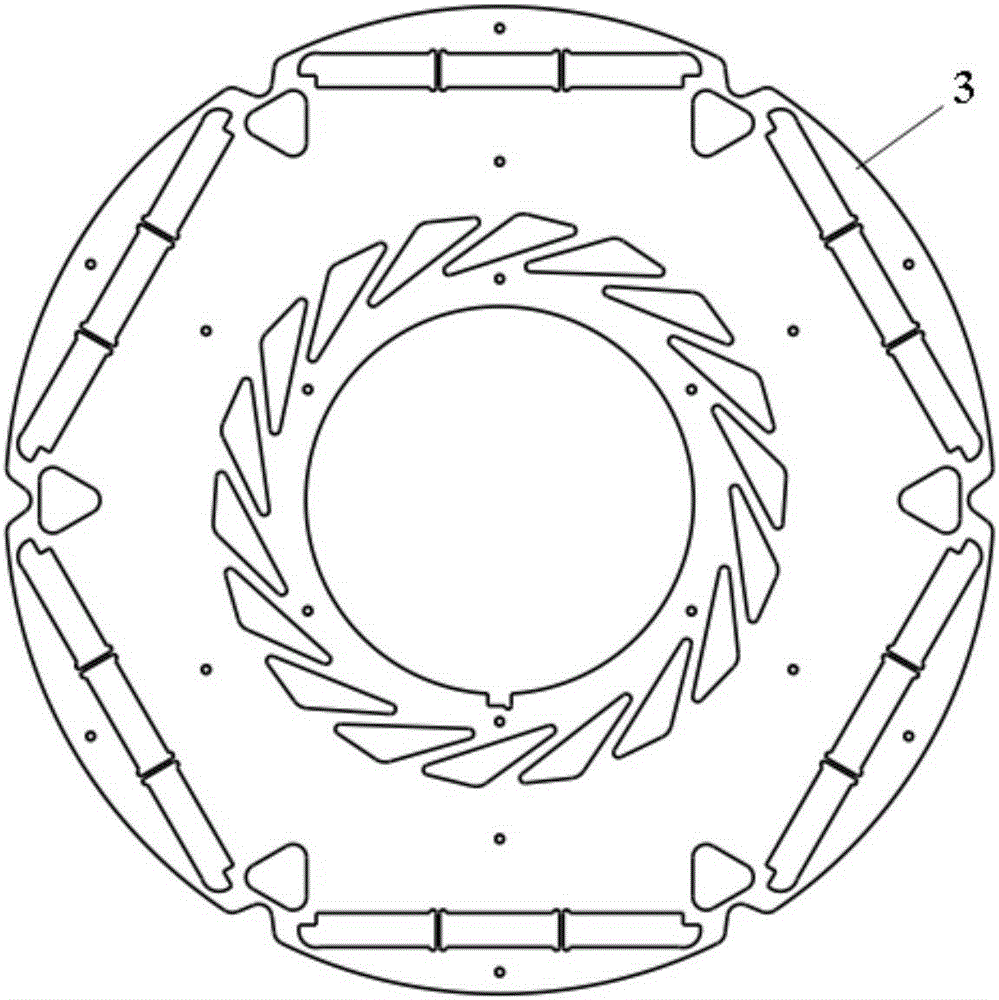

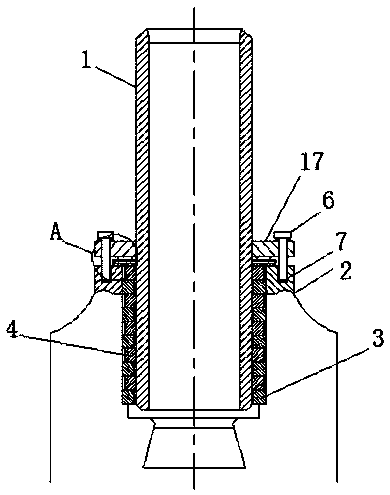

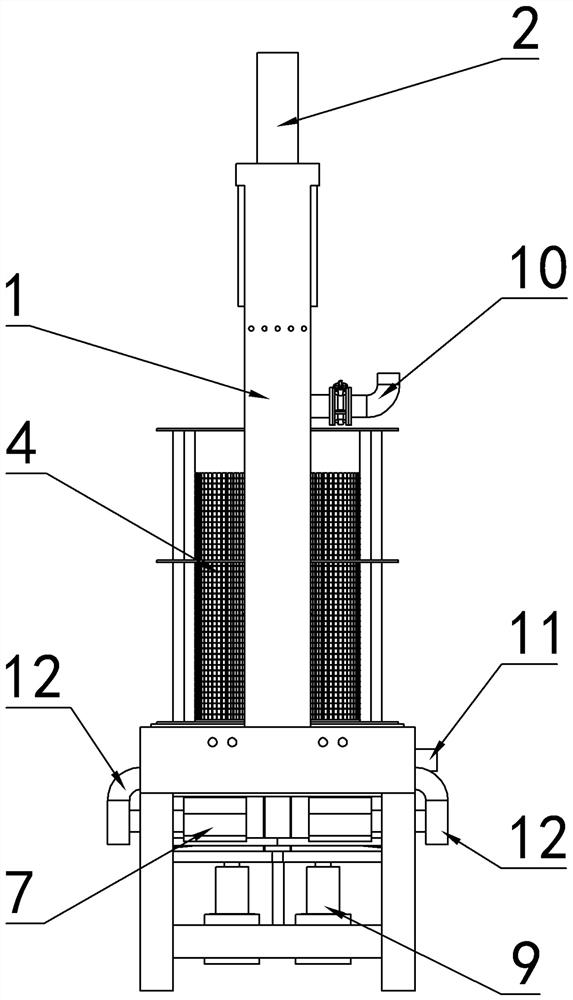

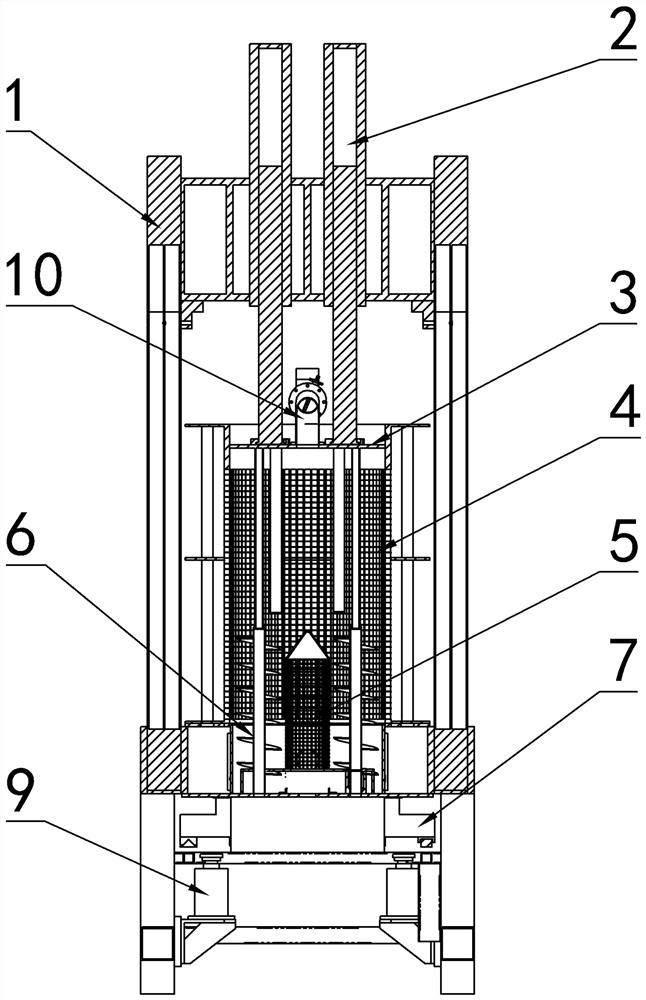

Unit magnetic pole structure of permanent magnet motor rotor

ActiveCN105245047AEasy to operateImprove reliabilityMagnetic circuit rotating partsManufacturing stator/rotor bodiesMagnetic polesPermanent magnet motor

The invention discloses a unit magnetic pole structure of a permanent magnet motor rotor. The unit magnetic pole structure comprises a rotating shaft and a rotor core, wherein the rotor core is axially divided into a plurality of independent unit magnetic poles, magnetic steel of each unit magnetic pole is axially fixed and sealed by a core ventilation pressure plate, magnetic pole cores are fixed by stainless steel rivets, and the unit magnetic poles are connected by ventilation slot plates and ventilation slot sheets. The unit magnetic pole structure has the advantages of novel structure, good performance and convenience in process, and is suitable for a high-speed rotating motor with high power density.

Owner:愿景动力有限公司

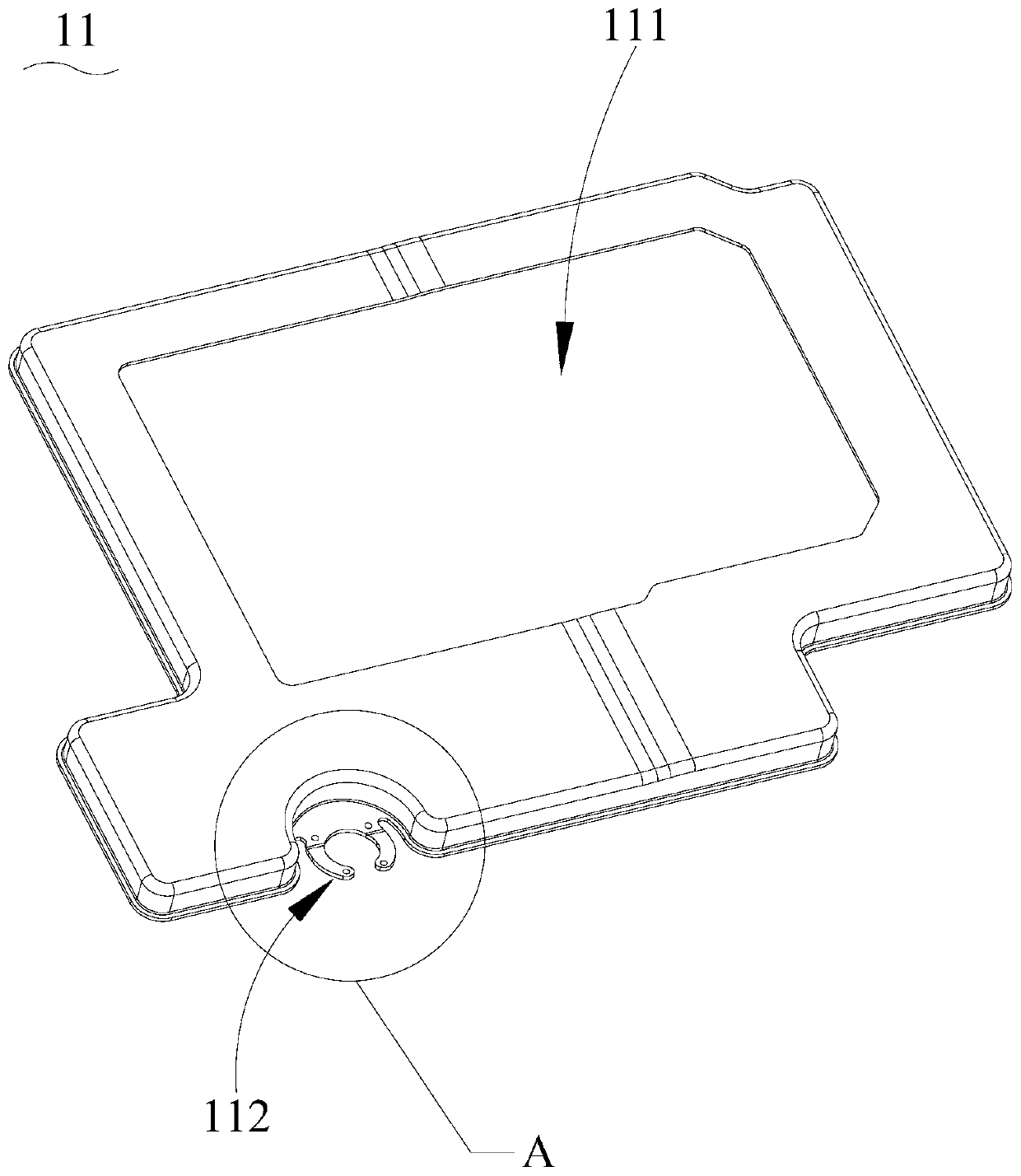

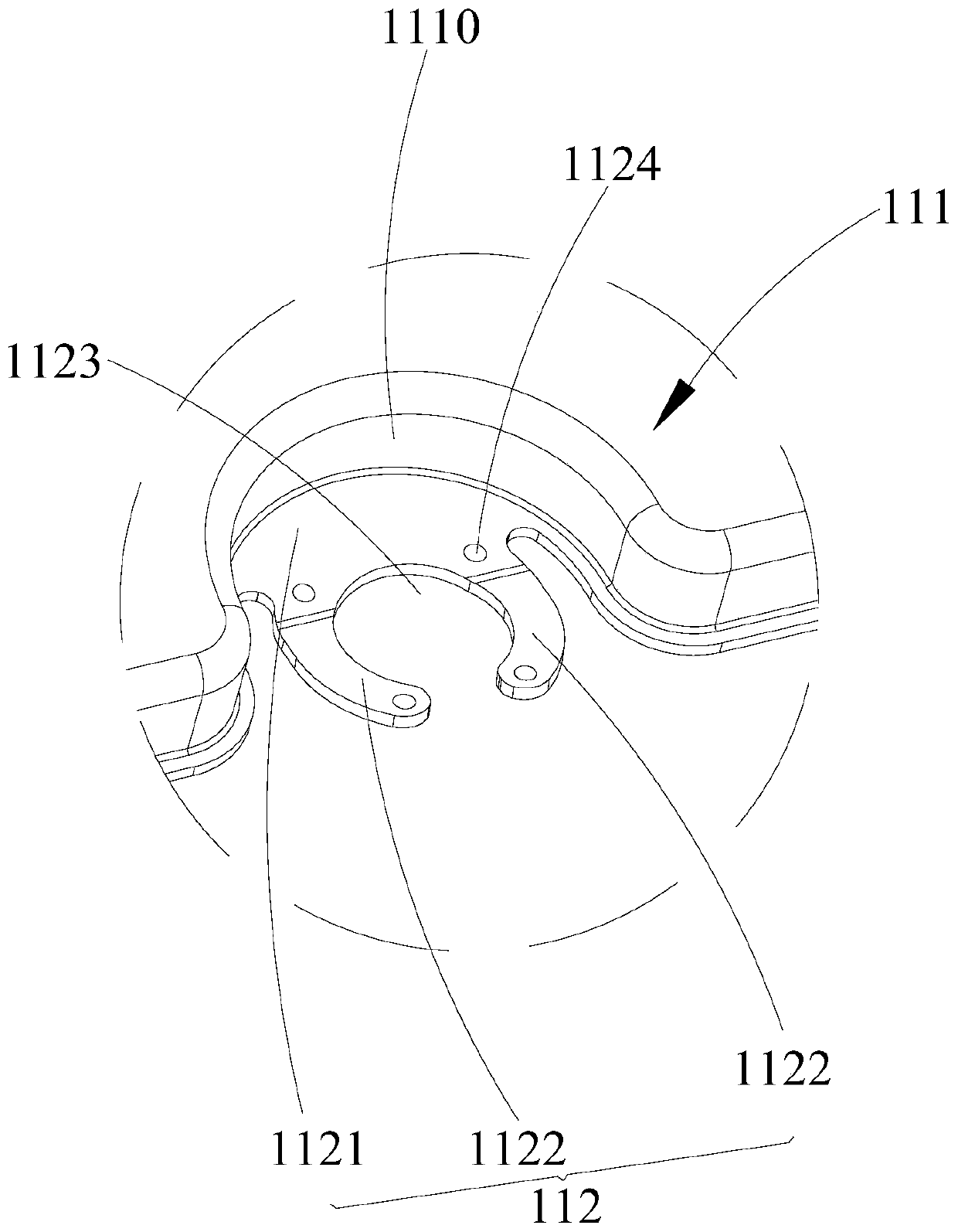

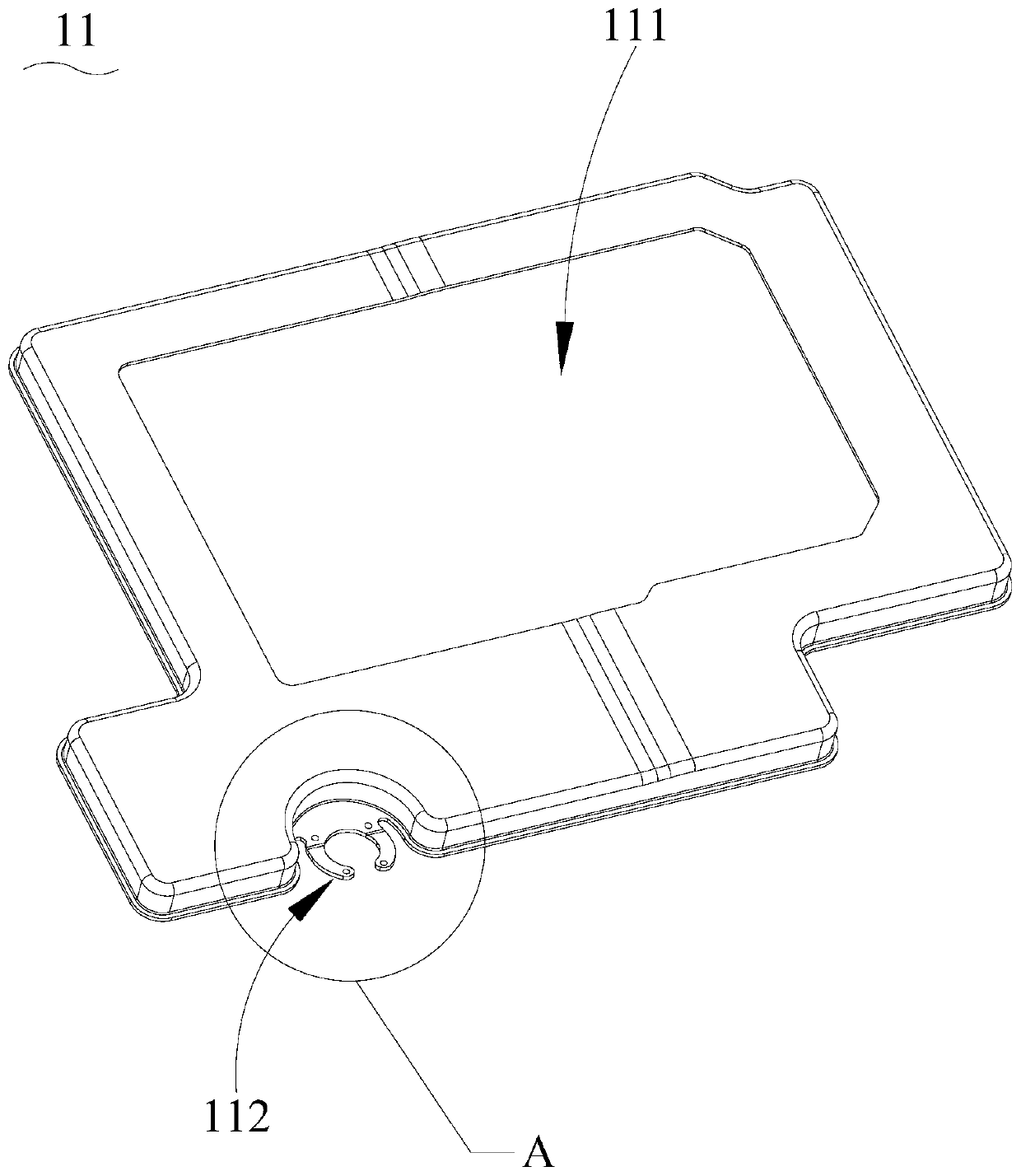

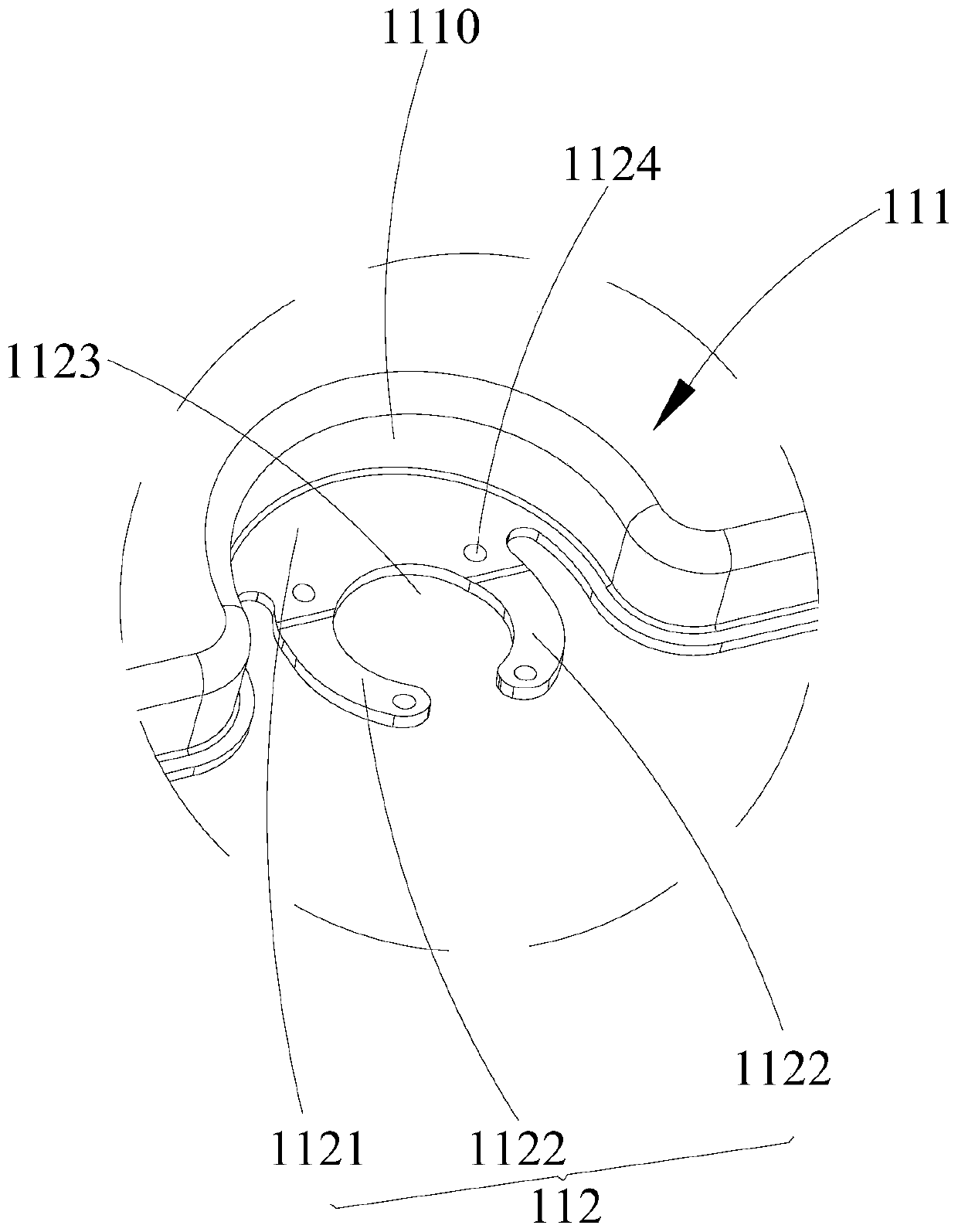

Shielding grounding structure and terminal equipment

ActiveCN110072331AReduce in quantityWill not harmPrinted circuit groundingCross-talk/noise/interference reductionMetal frameworkTerminal equipment

The invention relates to the technical field of electronic product manufacturing, and provides a shielding grounding structure and terminal equipment. The shielding grounding structure is used for electrically connecting a printed circuit board and a metal framework and comprises a shielding grounding unit, wherein the shielding grounding unit comprises a shielding cover and an elastic part, the shielding cover and the elastic part are integrally formed, the shielding cover is used for connecting the printed circuit board, and the printed circuit board is electrically connected with the metalframework by the elastic part so that the electrical conduction of the printed circuit and the metal framework is achieved. The shielding cover and the elastic part are integrally formed, thus, the elastic part can be simultaneously formed when the shielding cover is fabricated, the material number is reduced, and the fabrication cost is favorably reduced; and since the printed circuit board is electrically connected with the metal framework by the elastic part, the printed circuit board is prevented from being directly extruded during the connection process, so that no damage to the printed circuit board is generated.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Connecting joint for buckling-restrained brace and concrete frame beam

InactiveCN104563303AIncrease the welding areaReduce stress concentrationShock proofingBuckling-restrained braceConcrete beams

The invention discloses a connecting joint for a buckling-restrained brace and a concrete frame beam; an anchoring part is formed by integrally welding one group of spaced H-shaped profile steels and upper and lower anchoring plates; a joint plate is integrally welded with the lower anchoring plate; two ends of the lower anchoring plate are lengthened to be longer than the lateral side of the joint plate; and bolt holes for fixed connection of a buckling-restrained brace are formed at two sides of the joint plate. The joint has the advantages: the H-shaped profile steels have good stability in a vertical plane and are high in rigidness and not easy in unstability; the profile steels have big welded areas with the anchoring plates and are not easy to produce pulling / pushing damage; the profile steels have big contact and load-transfer areas with the concrete and are capable of uniformly dispersing the load to the concrete beam; the lengthened parts at two ends of the lower anchoring plate are capable of effectively avoiding direct extrusion between the joint plate and the concrete, so that the stress concentration is relieved and the service life of the joint is prolonged; a clearance is formed between two profile steels, the integrality of the concrete beam is not influenced, the arrangement of hoops and longitudinal ribs in the concrete beam is not influenced and the construction is convenient; the steel ratio in the joint area of the concrete beam is increased and the strength and rigidness of the joint is improved by the plastic deformation of the beam restrained by the upper and lower anchoring plates; the whole component can be manufactured in a factory and the construction time is saved.

Owner:SHENYANG JIANZHU UNIVERSITY

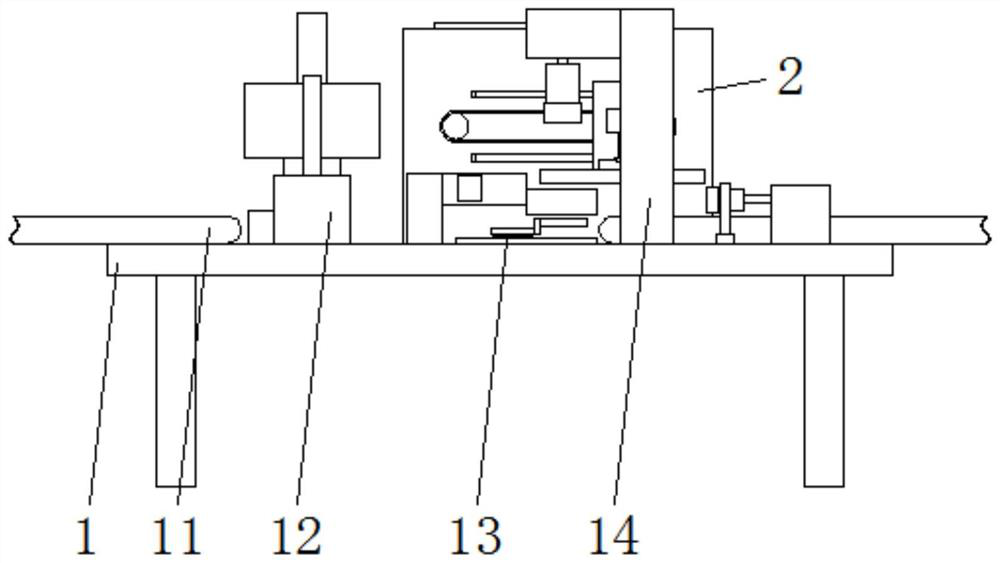

Numerical control machine tool clamping structure

InactiveCN111085881AImprove stabilityImprove reliabilityPositioning apparatusMetal-working holdersNumerical controlRound bar

The invention discloses a numerical control machine tool clamping structure in the field of automatic clamps to overcome the defect of unstable round bar clamping in the prior art. The clamping structure comprises a workbench, a front support plate and a rear support plate are fixed to the surface of the workbench, a gap for placing a round material is formed between the front support plate and the rear support plate, through holes are formed in the surface of the front support plate, the through holes are formed in the surface of the front support plate in a transverse row, and a pushing abutting device is arranged close to the front support plate. The pushing abutting device comprises a transverse plate, a screw rod and a sliding rail, wherein tension springs are arranged between the transverse plate and the through holes, the tension springs correspond to the through holes one to one, the diameter of the tension springs is larger than the aperture of the through holes, and through shafts penetrate through the tension springs. According to the device, the gap formed by the front support plate and the rear support plate is used for primary clamping of the round material, then thetransverse plate and the through shafts are sequentially driven by the screw rod to carry out secondary clamping on the round material, and the clamping stability and reliability are improved.

Owner:青海高等职业技术学院

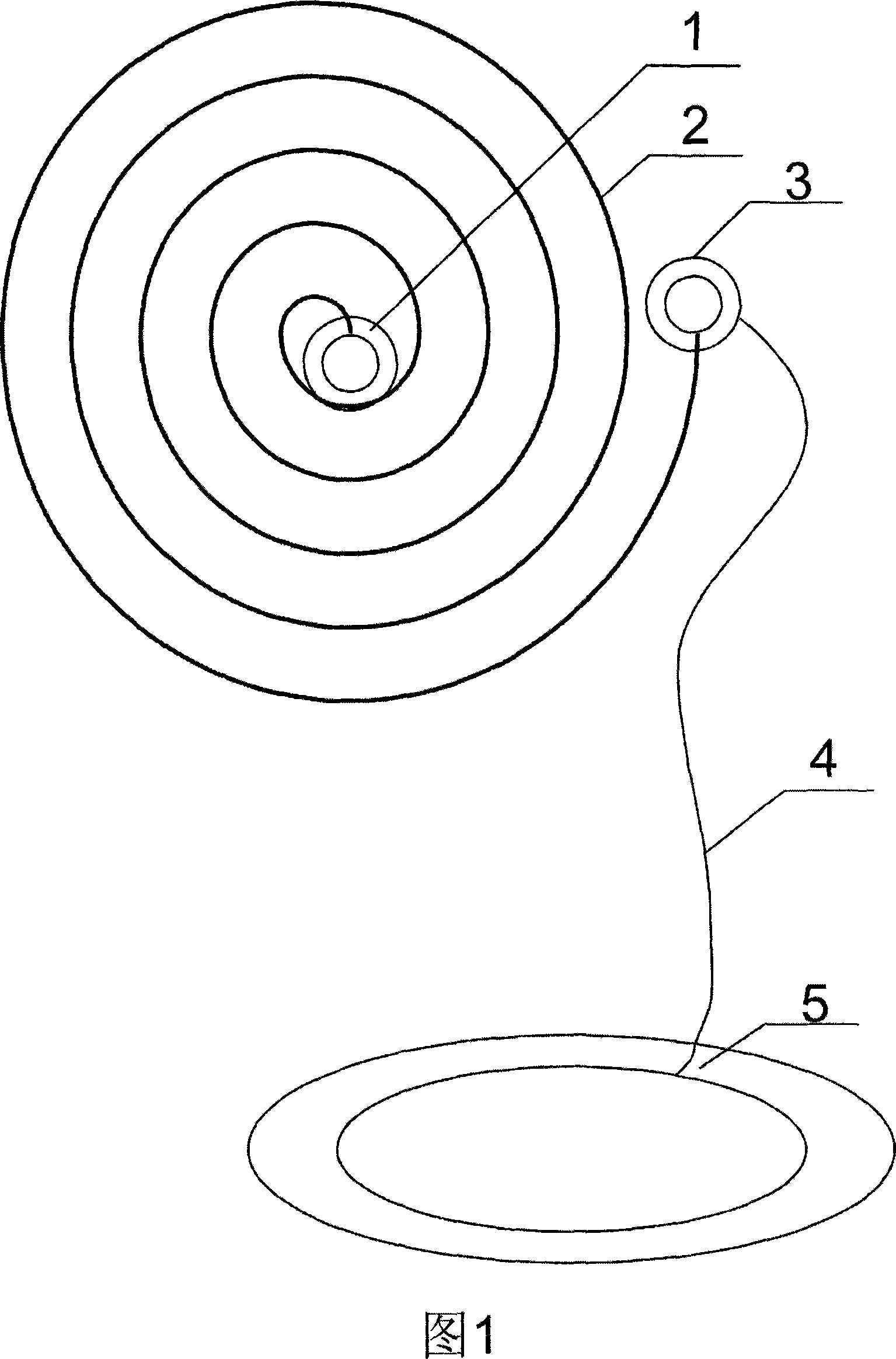

Finger joint flexible training device

InactiveCN101143258AReduce stiffnessIncrease slackResilient force resistorsDevices for pressing relfex pointsFinger-stallSacroiliac joint

The invention relates to a health care device, in particular to a health care and remedy device for the patients who have knuckle diseases, in particular for the people who undertake long-termed manual work. The knuckle agility trainer mainly consists of a health care finger-stall, a spring coil, a safety rope and a band, and wherein the health care finger-stall consists of a steel ring, a pressure sustained coil, a health care layer and a massage point. The two health care finger-stalls are separately fixed on the center and the edge of the spring coil, and are connected together by the safety rope and the band. Based on the motion mechanism of the knuckle and the construction of ligament and skeleton, and aiming at the lacking of knuckle nursing and health care in daily life and work, and through making effective flexible training and active exercise for the knuckle, the damage of the knuckle caused by long-time boring work, unhealthy operation, active sports and contingencies can be reduced. The invention has an excellent efficiency of disease prevention and health care, and is characterized by beautiful shape, health and legerity, simple structure, is convenient to be used and has a high performance-price ratio.

Owner:HENAN POLYTECHNIC UNIV

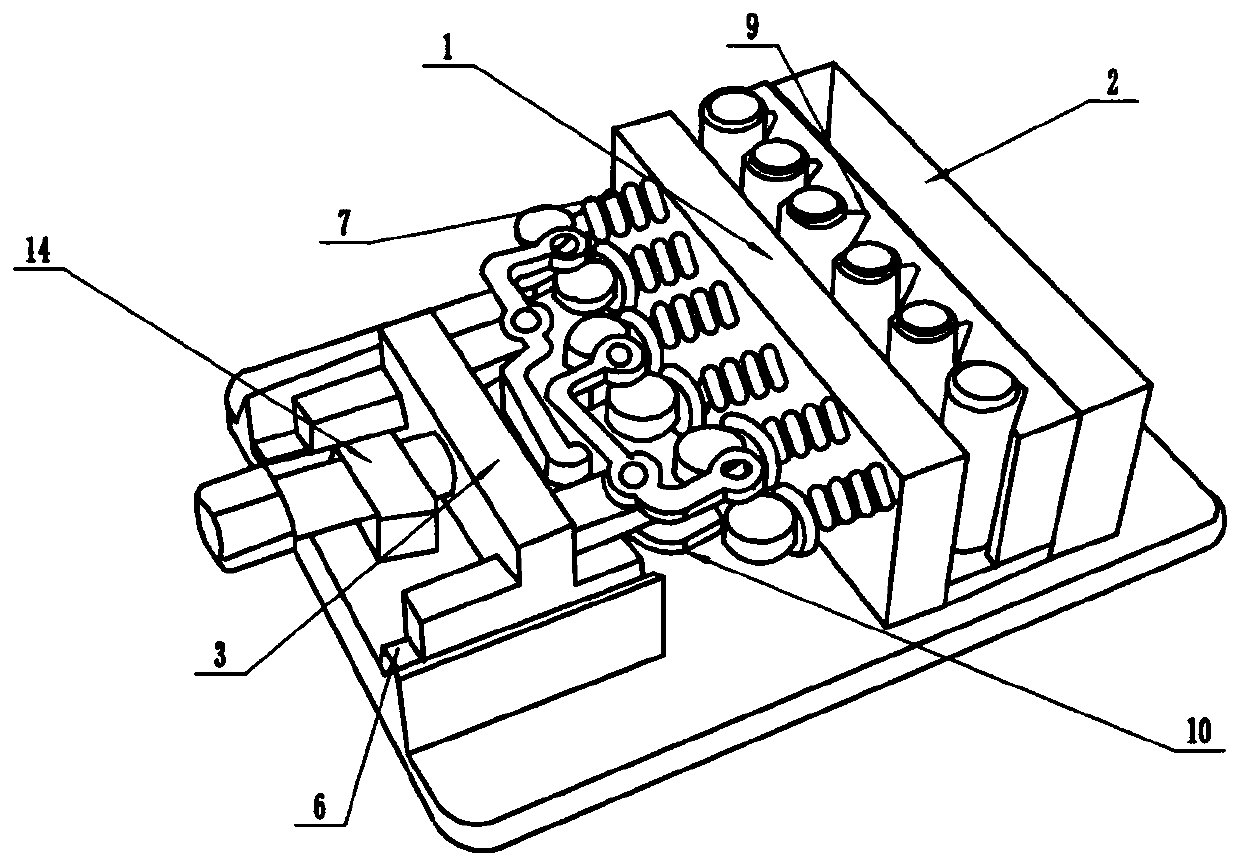

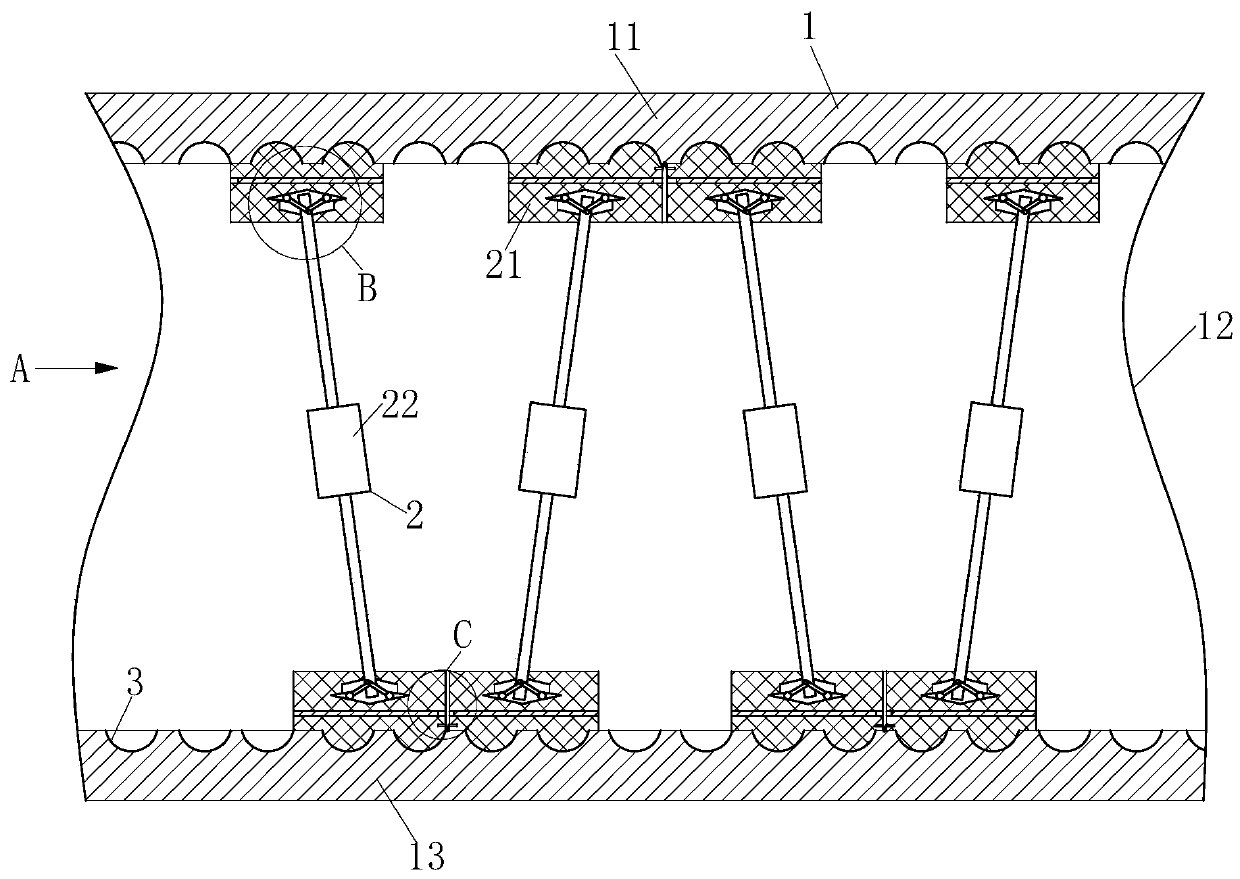

Assembled joist steel

InactiveCN109807198AReduce wearExtended service lifeElongated constructional elementsMetal-working feeding devicesEngineeringJoist

The invention belongs to the technical field of steel, and particularly relates to assembled joist steel. A joist steel body, correcting modules and a controller are included. The controller is used for controlling work of the correcting modules. The joist steel body comprises a first panel, a web and a second panel, wherein the web is vertically connected with the first panel and the second panel, and the first panel is located on the upper side of the second panel. A plurality of hemispherical grooves are evenly formed in the opposite side faces of the first panel and the second panel. The correcting modules are symmetrically distributed on the two sides of the web and obliquely placed, the adjacent correcting modules are opposite in inclination direction, a triangular structure is formed among the correcting modules, the first panel and the second panel, and each correcting module comprises a supporting plate and a double-shaft hydraulic cylinder. A shaft sleeve is arranged on one side of each supporting plate, a hemispherical protrusion is arranged on the other side of each supporting plate, and the protrusions are engaged with the hemispherical grooves. The end portions of piston rods of the double-shaft hydraulic cylinders are inserted in the shaft sleeves of the supporting plates, and the double-shaft hydraulic cylinders stretch and contract at the same time.

Owner:湖南润鑫建设有限公司

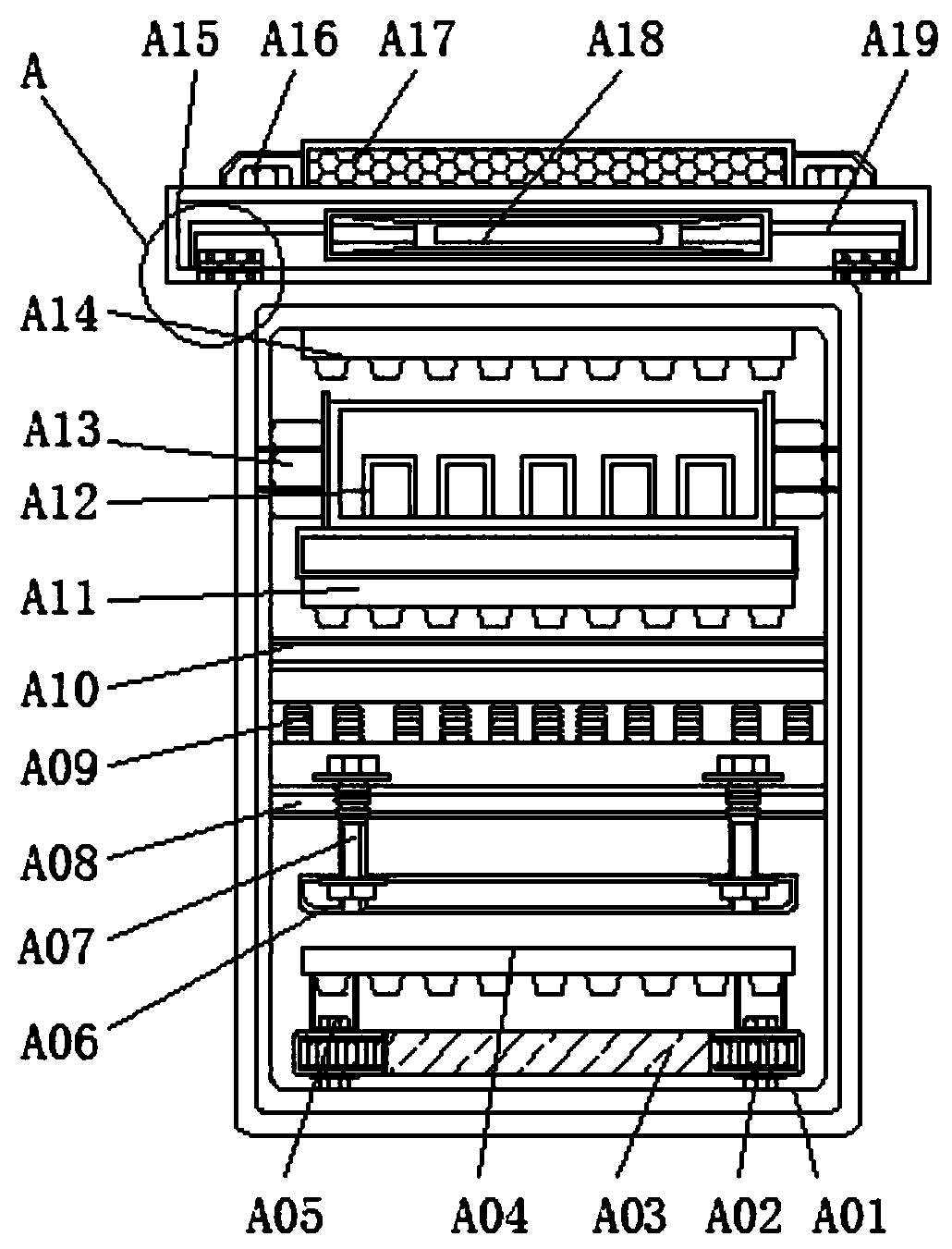

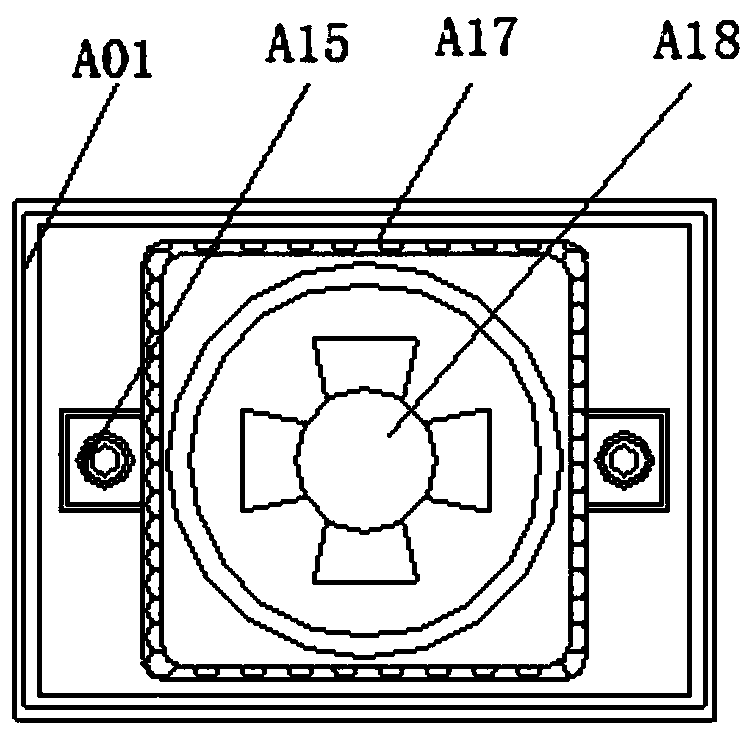

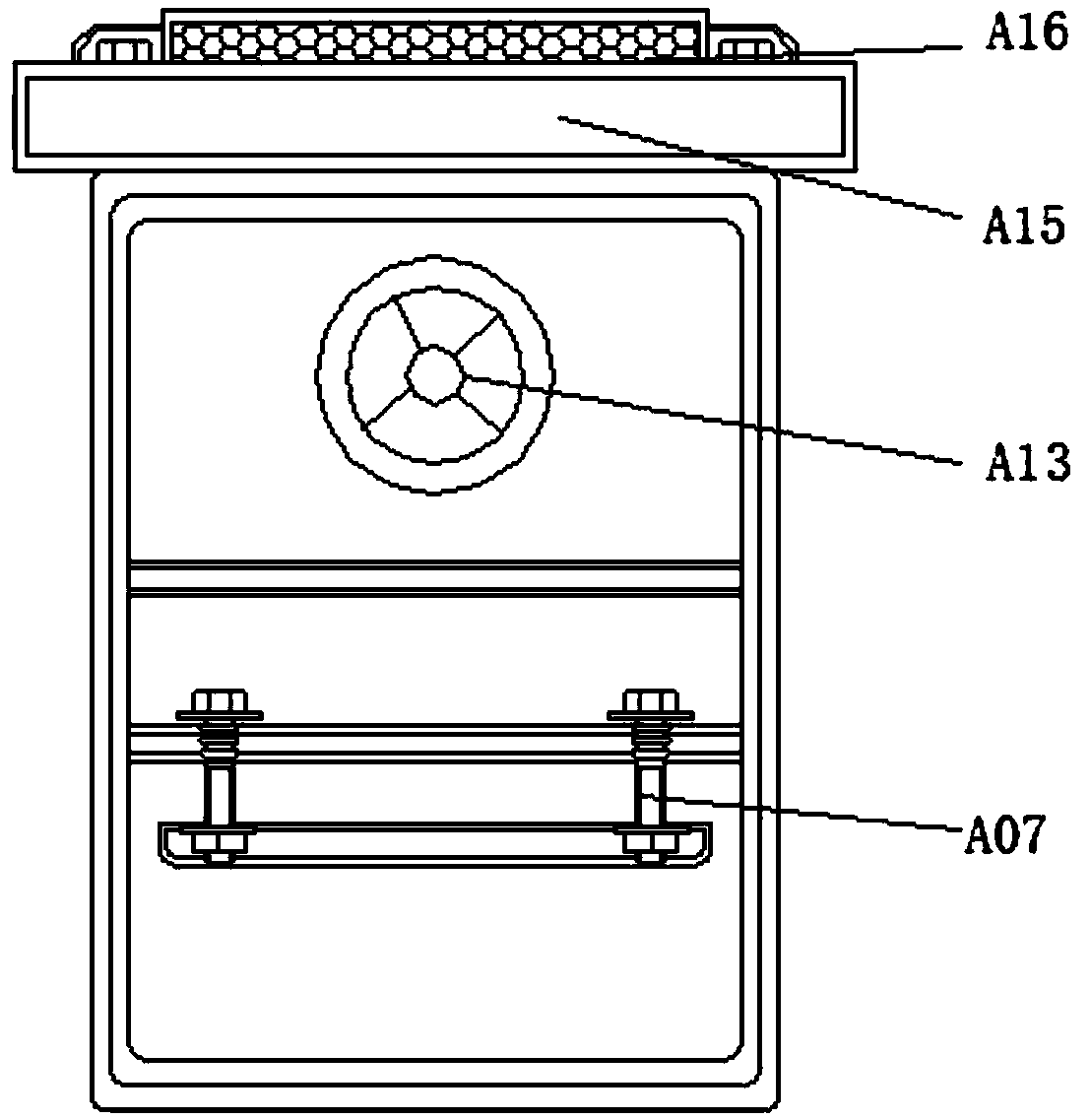

Karst geological environment intelligent monitoring device

PendingCN113671584AImprove stabilityHigh precisionWater resource assessmentStands/trestlesKarstEngineering

The invention relates to the technical field of karst geological equipment, and discloses a karst geological environment intelligent monitoring device which comprises a geological radar and a mounting box used for mounting the geological radar. Adjusting mechanisms are mounted on the two sides of the mounting box, each adjusting mechanism comprises a supporting plate fixed to the mounting box, a first telescopic set is arranged on one side of each supporting plate, and a second telescopic set is arranged on the other side of each supporting plate. A first detection system is arranged on one side of the mounting box in the length direction, and a second detection system is arranged on the other side of the mounting box in the width direction. A controller is installed on the mounting box, the first detection system and the second detection system detect whether the mounting box is horizontal or not, and based on judgment of the controller, the controller controls a first telescopic assembly and a second telescopic assembly to adjust the position of the mounting box. The device is simple in structure, so that the geological radar is in a horizontal state, and monitoring errors are reduced.

Owner:CHANGCHUN INST OF TECH

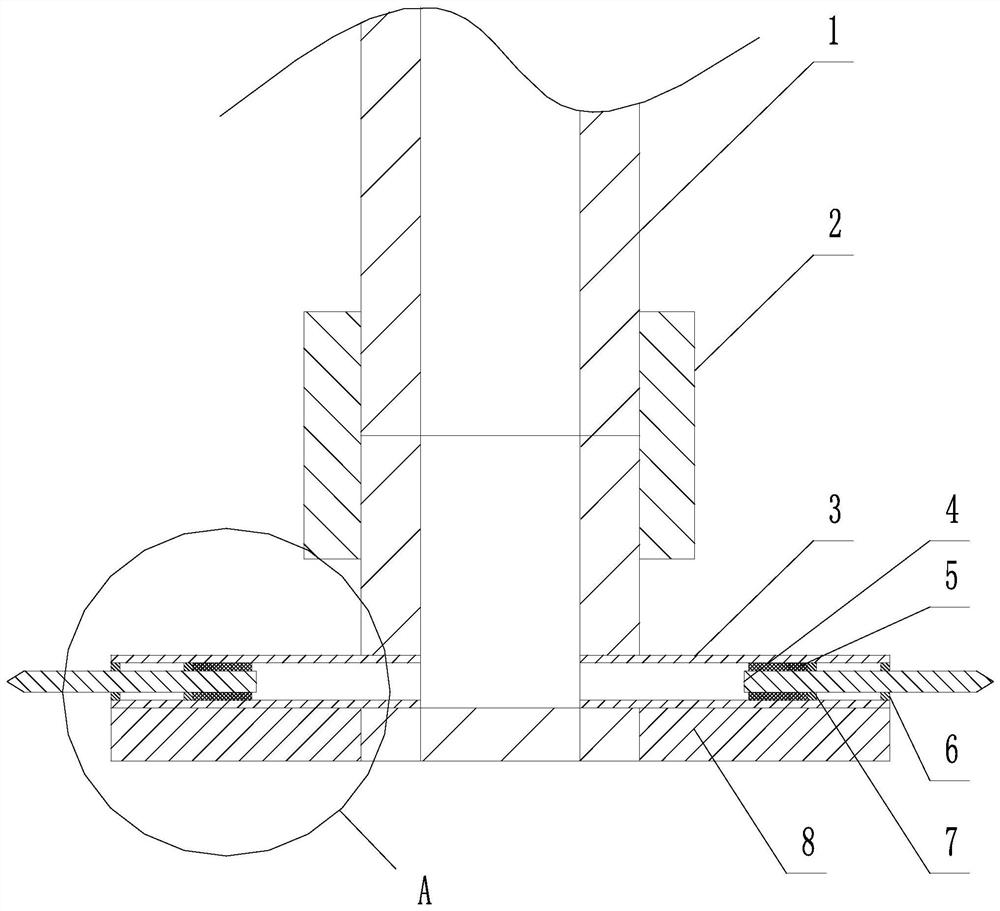

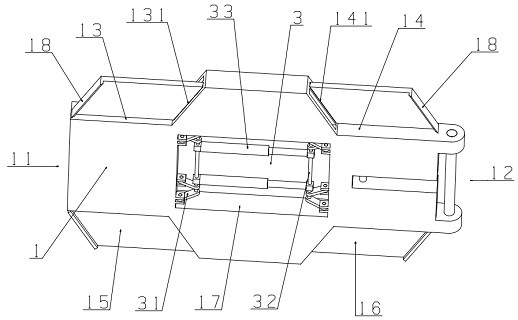

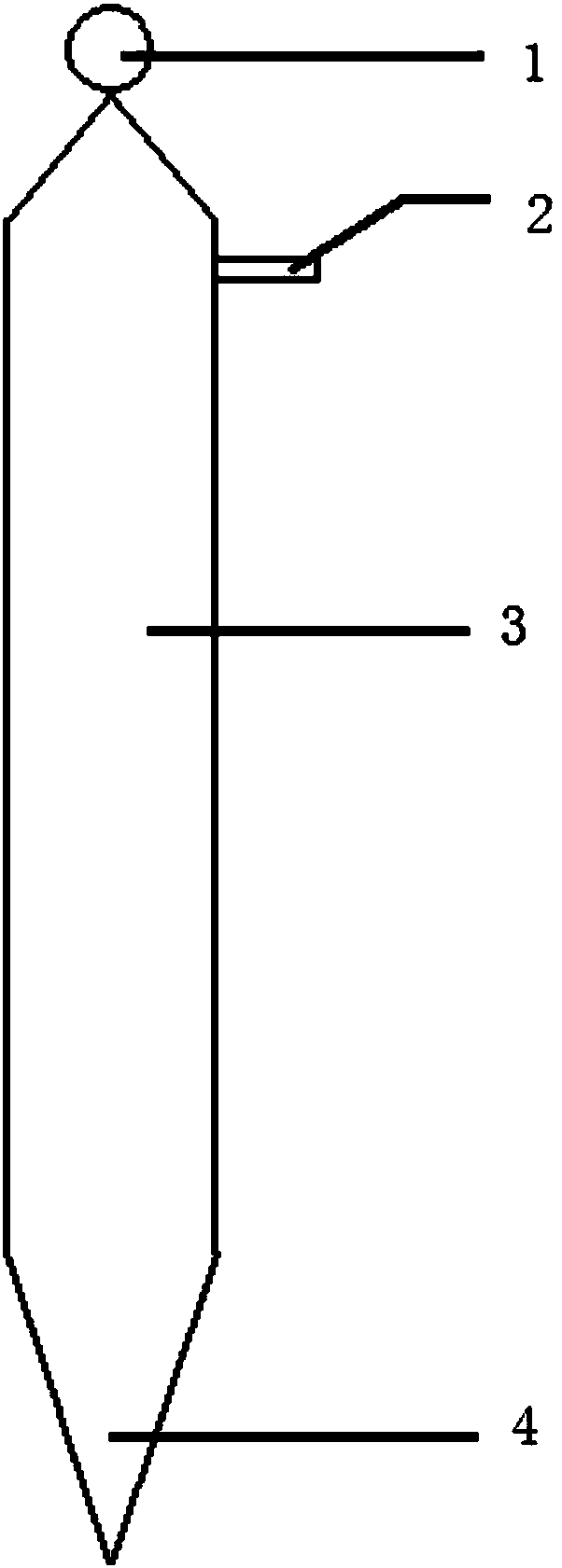

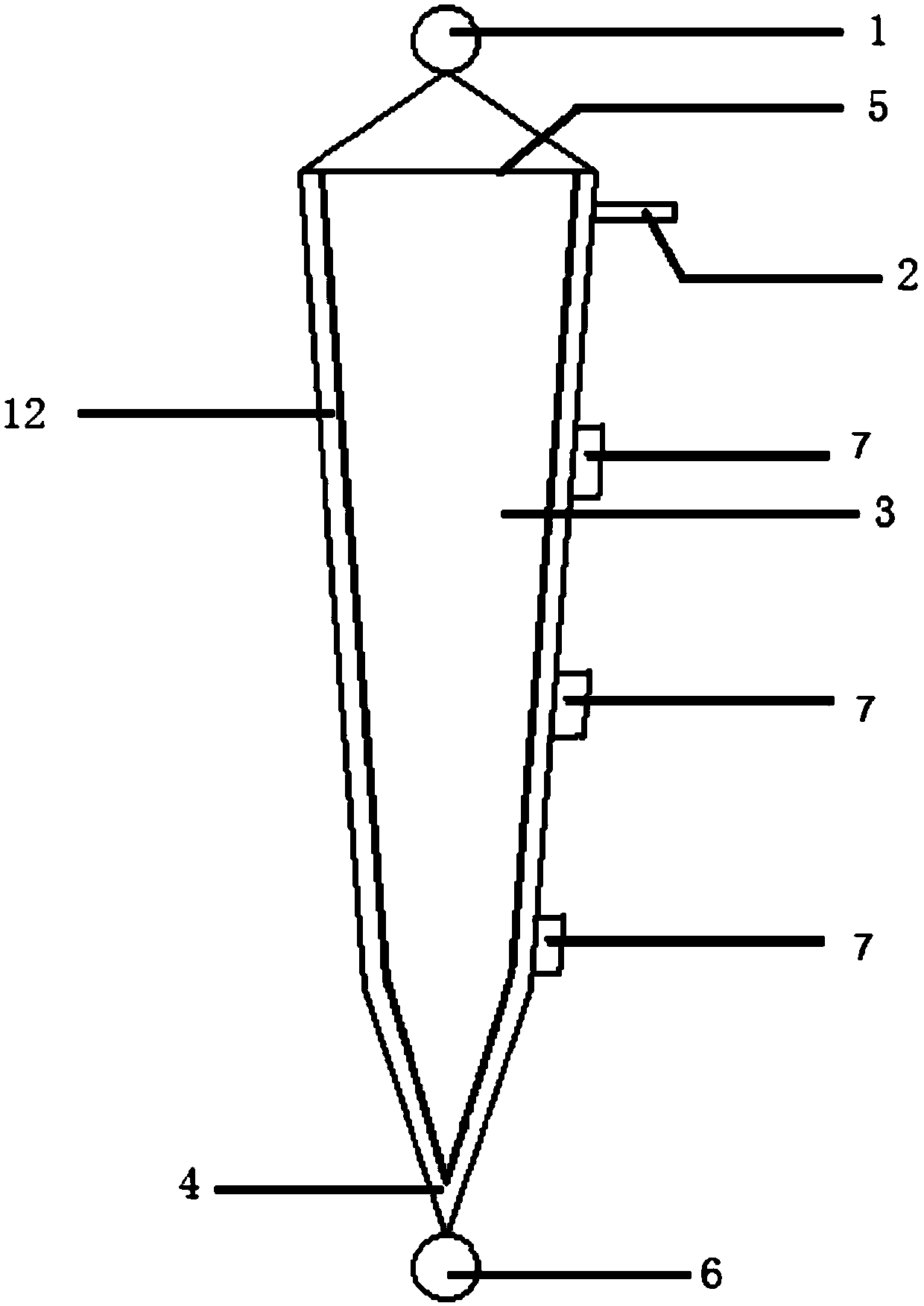

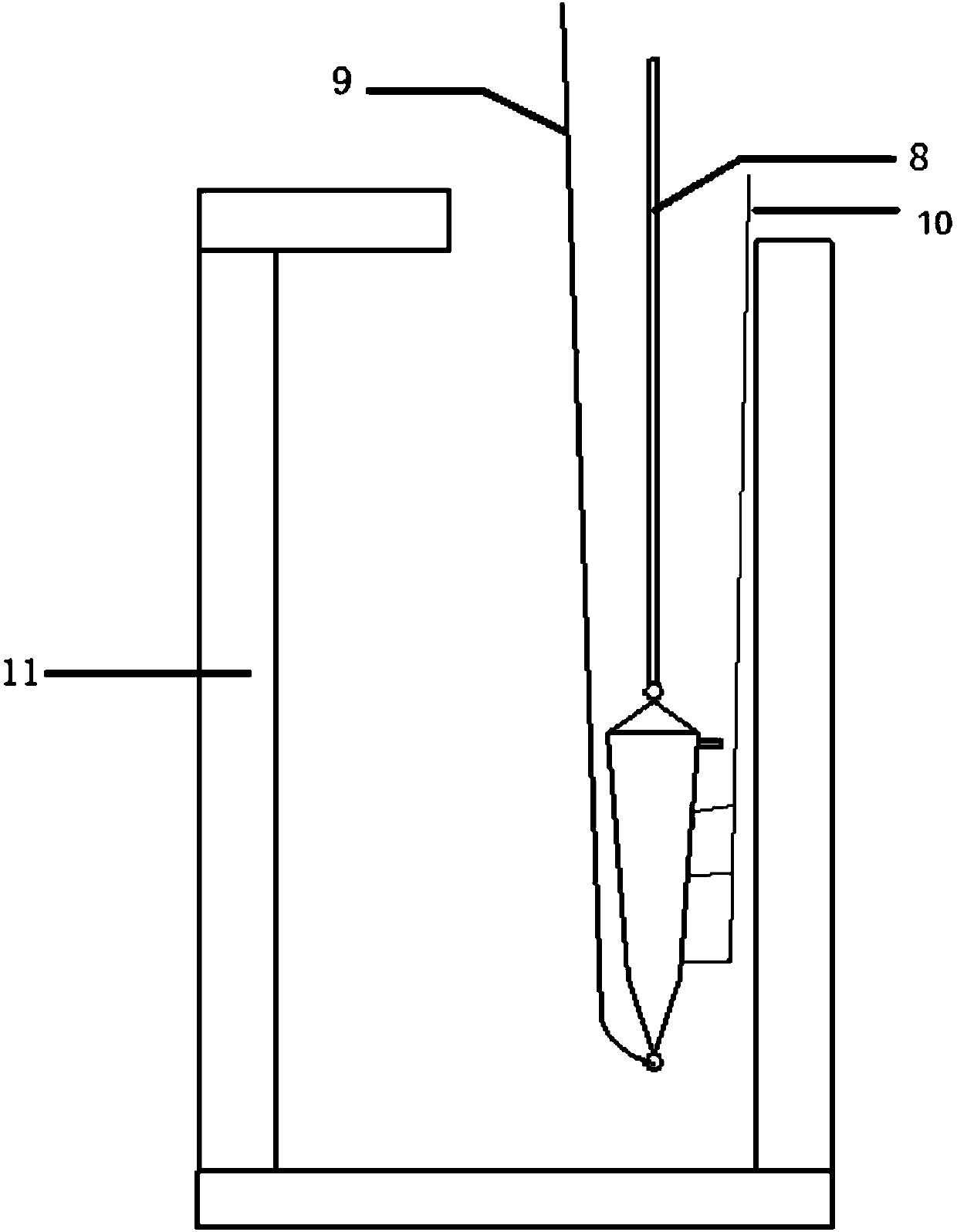

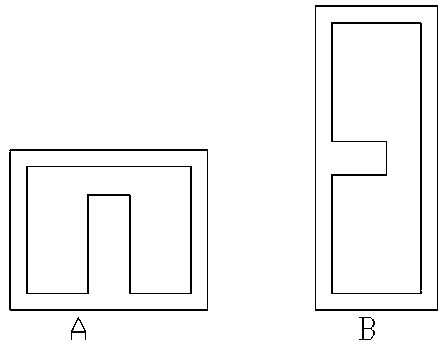

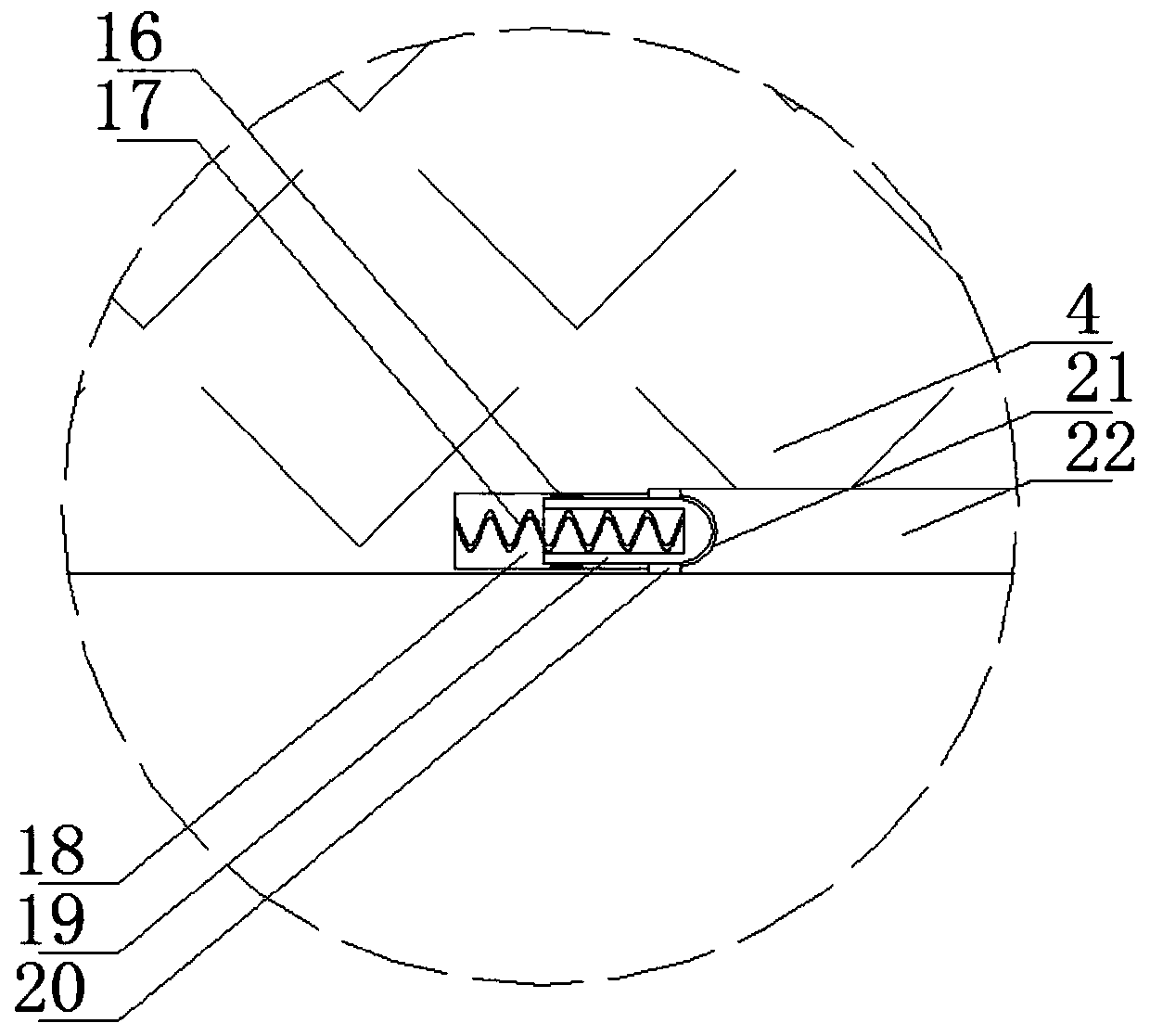

Ground subsidence value monitoring device and method

PendingCN111910695AAvoid failureAvoid direct extrusionFoundation testingGround subsidenceStructural engineering

The invention discloses a ground subsidence value monitoring device and method. The ground subsidence value monitoring device comprises a subsidence rod, and further comprises an insertion assembly. The insertion assembly comprises a barrel section and an inserting rod, and one end of the barrel section is fixedly connected with the subsidence rod; the inserting rod is located on the inner side ofthe barrel section, the length direction of the inserting rod is parallel to the length direction of the barrel section, and the inserting rod can slide in the barrel section in the length directionof the barrel section; and sealing filler is further arranged between the end, close to the subsidence rod, of the inserting rod and the inner wall of the inserting rod and used for achieving axial sealing of a gap between the inserting rod and the barrel section. A limiting device used for limiting the position of the sealing filler in the length direction of the inserting rod is further included; and a restraining device used for restraining the extending length of the inserting rod relative to the free end of the barrel section is further included. The method is based on the device. By adopting the device and method provided by the scheme, the precision of bottom face subsidence monitoring based on the subsidence rod can be optimized, and meanwhile, the device and method have the characteristic of convenience in installation.

Owner:CITIC GUOAN CONSTR GRP CO LTD

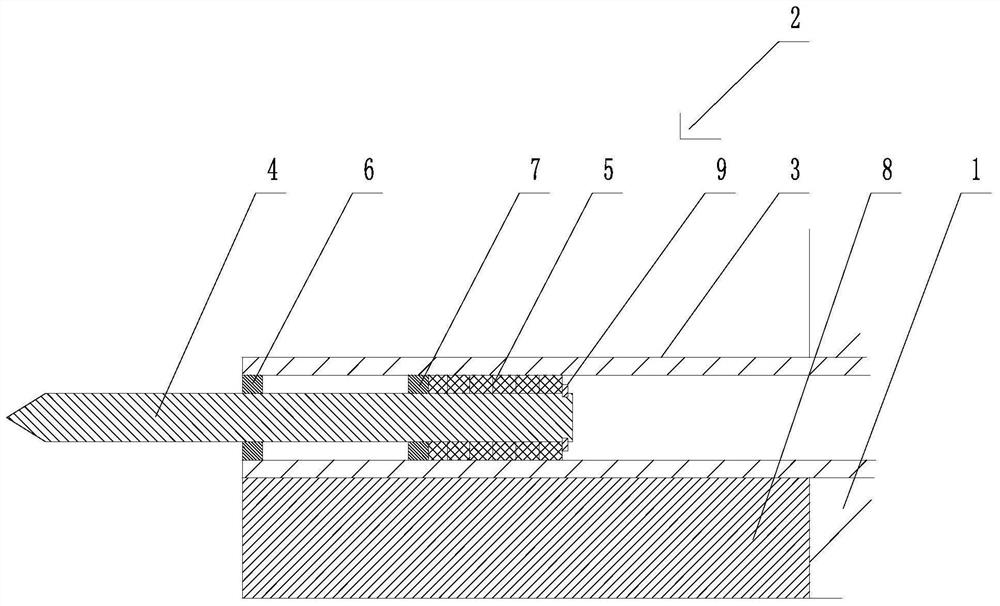

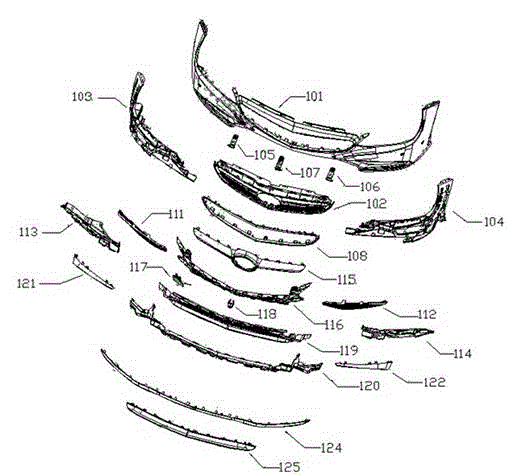

Steam turbine high-pressure steam inlet inserting pipe stacked piece type sealing device

ActiveCN109519227AAvoid extrusion deformationIncrease contact areaLeakage preventionMachines/enginesEngineeringHigh pressure

The invention discloses a steam turbine high-pressure steam inlet inserting pipe stacked piece type sealing device comprising a steam inlet inserting pipe and a high-pressure inner cylinder. The outerside of the steam inlet inserting pipe is sleeved with a plurality of outer sealing rings and a plurality of inner sealing rings. The multiple outer sealing rings and the multiple inner sealing ringsare arranged at intervals. The steam inlet inserting pipe is further sleeved with a sleeve plate and a pressing ring. The sleeve plate is located between the pressing ring and the high-pressure innercylinder. An annular rubber pad is fixedly connected to the bottom side of the sleeve plate. The sleeve plate is symmetrically provided with telescopic grooves. Elastic mechanisms are arranged in thetelescopic grooves. An extrusion block is connected to the sleeve plate through the elastic mechanisms. When the pressing ring presses the extrusion block down, the extrusion block moves down, a second spring is driven to compress, meanwhile a movable wedge block slides through a bevel on the extrusion block and a slope end face on a movable wedge block, then a first spring starts to compress, buffering is conducted through elastic force generated by compression of the first spring and the second spring, and the pressing ring is prevented from directly pressing the sealing rings.

Owner:JIANGSU MARITIME INST

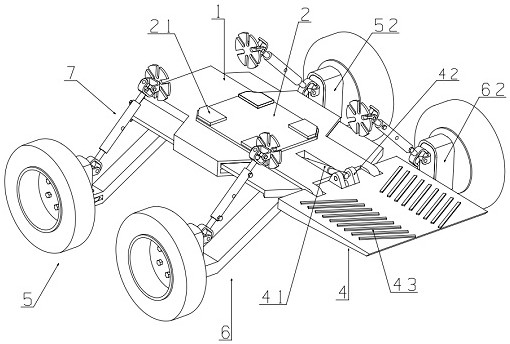

Sugarcane mechanical harvest auxiliary device capable of reducing mechanical harvest rolling compaction

PendingCN113728797AAvoid direct extrusionReduce the rate of broken headsHarvestersVehiclesAgricultural engineeringAgricultural science

The invention relates to the field of sugarcane harvesters, and particularly discloses a sugarcane mechanical harvest auxiliary device capable of reducing mechanical harvest rolling compaction, which comprises a bottom plate with a front wheel abdicating opening and a rear wheel abdicating opening, a liftable fixed plate with an electromagnet, a turnover plate, a front wheel assembly capable of changing the direction, a rear wheel assembly capable of changing the direction, and a transmission shaft assembly with a connecting flange and a universal ball joint. According to the device, a sugarcane harvester is fixed on the bottom plate through the fixed plate with the electromagnet and is suspended in the air, so that a chassis of the sugarcane harvester is elevated, and then through a front wheel and a rear wheel with wide wheel track, a pressing point during harvesting is located between sugarcane stumps; hubs or crawler wheels of the harvester are connected with the input ends of a front gear box and a rear gear box through the transmission shaft assembly, when the harvester is started, the device can be driven to walk, the device can be universally used for wheel type or crawler type harvesters, direct extrusion on sugarcane stumps is avoided, and therefore, the adverse effect of machine harvesting and rolling on the ratoon sugarcane is effectively relieved.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Method for reducing breakage rate of quartz tubes during preparation of scintillation single crystals

ActiveCN107675247AThere will be no ups and downsLess micro defectsPolycrystalline material growthVacuum evaporation coatingRoom temperatureScintillation crystals

The invention discloses a method for reducing the breakage rate of quartz tubes during the preparation of scintillation single crystals. The method comprises the following steps: drawing a quartz tubeinto a hetero-shaped quartz tube with a thick upper part and a thin lower part, coating the inner wall of the quartz tube with a film, mounting a strain gage on the outer wall of the quartz tube, controlling the growth speed of a single crystal through the feedback of strain amplitude, preventing the breakage of the quartz tube, inverting the hetero-shaped quartz tube after a crystal is formed, and taking out a scintillation crystal after the scintillation crystal is cooled to room temperature. The method has the advantages that the inner wall of the hetero-shaped quartz tube is coated with the film before a single crystal material is loaded, conglutination between the hetero-shaped quartz tube and the produced crystal can be avoided, complete separation of the produced crystal and the hetero-shaped quartz tube body is facilitated, the quartz tube can be prevented from directly extruding the crystal, the method is convenient for reducing micro defects of the crystal, the probability of self-absorption of the crystal is reduced, the cracking risk of the crystal is reduced, the internal performance of the scintillation crystal is obviously improved, in addition, after crystal growthand cooling after accomplished, the quartz tube is not required to be broken to take out the crystal, all that is needed is to open the quartz tube and pour out the crystal, and the quartz tube can be reused after being cleaned.

Owner:NORTHEASTERN UNIV

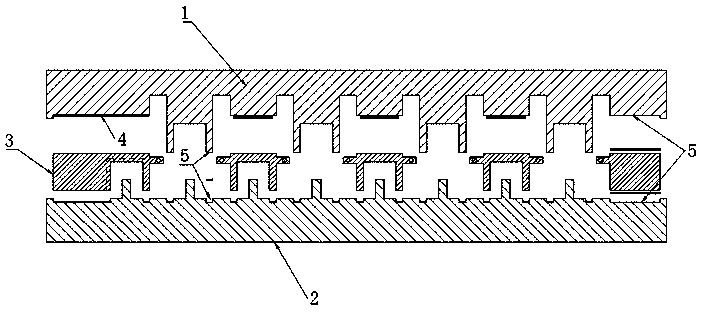

Integrated wide-narrow ridge waveguide and manufacturingprocess thereof

The invention relates to an integrated wide-narrow ridge waveguide and a manufacturing process thereof. The waveguide comprises an upper cavity, a lower cavity and a plurality of middle cavities, wherein waveguide cavities are formed between the upper cavity and the lower cavity, the middle cavities are uniformly distributed between the waveguide cavities, each waveguide cavity is divided into wide-side ridge waveguides and narrow-wave ridge waveguides which are sequentially alternated, the upper cavity, the lower cavity and the middle cavities are positioned through seam allowance structures,and brazing filler metal is embedded into grooves of the seam allowance structures in advance. According to the scheme, the waveguide is divided into the upper cavity, the lower cavity and the plurality of middle cavities; then, positioning among the upper cavity, the lower cavity and the plurality of middle cavities is completed by utilizing the seam allowance structures, and the brazing fillermetal is embedded into the seam allowance grooves in advance; after the positioning is completed, welding of a product is completed through vacuum brazing; and compared with a traditional extrusion technology, by using the process of the invention, precision of a product manufactured through the scheme is higher, deformation caused by extrusion cannot be generated, and the product precision is greatly improved.

Owner:CHENGDU JINJIANG ELECTRONICS SYST ENG

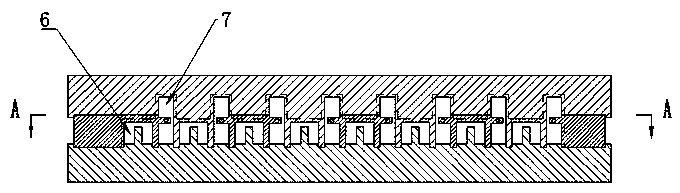

Automobile front bumper structure

InactiveCN105329195AImprove protection performanceImprove the protective effectBumpersTruckAutomobile safety

The invention provides an automobile front bumper structure comprising a front bumper main body, a middle net main body, a front bumper lining right rack, a front bumper lining left rack, a middle net truck loading right rack, a middle net truck loading left rack, a middle net truck loading middle rack, a middle net protection bar, a right ventilating window grid, a left ventilating window grid, a ventilating window right pedestal, a ventilating window left pedestal, a middle net supporting frame, a front bumper lining rack, a front bumper truck cover, a middle electric eye rack, a lower protection plate, a lower protection lining rack, a right foglight eyebrow frame, a left foglight eyebrow light, a front bumper lower protection bar and a front bumper reinforcing plate. The front bumper structure has high protection performance and can effectively improve automobile safety.

Owner:JIANGSU GAOBIAO TECH DEV

A laminated sealing device for high pressure steam inlet tube of steam turbine

ActiveCN109519227BAvoid direct extrusionAvoid extrusion deformationLeakage preventionMachines/enginesEngineeringMechanics

The invention discloses a steam turbine high-pressure steam inlet inserting pipe stacked piece type sealing device comprising a steam inlet inserting pipe and a high-pressure inner cylinder. The outerside of the steam inlet inserting pipe is sleeved with a plurality of outer sealing rings and a plurality of inner sealing rings. The multiple outer sealing rings and the multiple inner sealing ringsare arranged at intervals. The steam inlet inserting pipe is further sleeved with a sleeve plate and a pressing ring. The sleeve plate is located between the pressing ring and the high-pressure innercylinder. An annular rubber pad is fixedly connected to the bottom side of the sleeve plate. The sleeve plate is symmetrically provided with telescopic grooves. Elastic mechanisms are arranged in thetelescopic grooves. An extrusion block is connected to the sleeve plate through the elastic mechanisms. When the pressing ring presses the extrusion block down, the extrusion block moves down, a second spring is driven to compress, meanwhile a movable wedge block slides through a bevel on the extrusion block and a slope end face on a movable wedge block, then a first spring starts to compress, buffering is conducted through elastic force generated by compression of the first spring and the second spring, and the pressing ring is prevented from directly pressing the sealing rings.

Owner:JIANGSU MARITIME INST

Punching cutting tool

InactiveCN109015868ASimple structureAvoid direct extrusionPerforating toolsCleaning using gasesEdge surfacePunching

The invention discloses a punching cutting tool. A cutting tool parent body is a cylindrical Cr12. A ventilation hole is formed in the middle of the cutting tool parent. A first sharp angle formed bya cutting tool point surface and an outer edge surface is arranged to be a cutting tool nose. The angle of a second sharp angle formed by a cutting tool body surface and the outer edge surface of thecutting tool is less than the angle of the first sharp angle formed by the cutting tool point surface and the outer edge surface. The sharp angle formed by the cutting tool point surface and the outeredge surface is between 15 and 25 degrees. The sharp angle formed by the cutting tool body surface and the outer edge surface is between 5 and 10 degrees. The cutting tool parent body needs to be subjected to heat processing after machining. The punching cutting tool is simple in structure. Through arrangement of the ventilation hole in the cutting tool parent body, waste material stuck on a cutting tool head can be automatically ejected out by connecting air pressure, and application is convenient. After the Cr12 is subjected to heat processing, achieved hardness is capable of dealing with different punching metal materials. The service life is long, and machining accuracy is high.

Owner:TAICANG RONGZHONG ELECTRIC CO LTD

A push-and-twist glove box lock structure

ActiveCN105370115BSimple structureLow costNoise-prevention/anti-rattling lockingLinear motionRelative motion

The invention relates to a button-type glove-box lock structure which comprises a left lock rod, a right lock rod and lock rod sleeves fixed on an outer glove-box plate and further comprises a button, wherein a transmission mechanism is connected between the left lock rod and the right lock rod; the button is provided with a cover-like casing; the closed end of the cover-like casing faces the outside; the cover-like casing is provided with a first connecting column and protruding columns, which face the inside; and the transmission mechanism comprises a transmission piece, a lock seat and an elastic piece used for connecting the transmission piece and the lock seat. According to the lock structure adopting the scheme, a glove box can be opened by pressing the button; the protruding columns are arranged on the button, circular arc-shaped grooves corresponding to the protruding columns are formed in the transmission piece, and the bottom surfaces of the circular arc-shaped grooves are wedge surfaces, so that the linear motion of the button is converted into the rotary motion of the transmission piece through the relative motion of the protruding columns on the wedge surfaces; and the transmission piece rotates to drive the left lock rod and the right lock rod to do axial linear motion to open the glove box. The scheme solves the problem that the conventional lock structure is complex in structure and inconvenient to operate.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Computer keyboard convenient to fold and capable of effectively protecting keys

InactiveCN111290620AGuaranteed stabilityGuaranteed temperatureInput/output for user-computer interactionKey pressingSoftware engineering

The invention discloses a computer keyboard convenient to fold and capable of effectively protecting keys. The keyboard comprises a first body, a second body and a third body, the second body is located between the first body and the third body, fifth notches are formed in the lower ends of the opposite sides of the first body and the third body, pushing mechanisms are arranged in the fifth notches, connecting blocks are arranged on the pushing mechanisms, and two fourth notches are formed in each connecting block. According to the invention, the distances and angles among the first body, thesecond body and the third body can be rapidly adjusted; therefore, the purpose of adjusting the position relationship between the bodies is achieved, the length of the body can be reduced, the keyboard keys can be well protected through the baffle, the keyboard keys can be prevented from being directly extruded by foreign objects, then the purposes of conveniently folding, placing and protecting the keyboard can be achieved, a user can carry the keyboard conveniently, the angle of the keyboard in use can be adjusted and fixed, and the use comfort is improved.

Owner:汪华衡

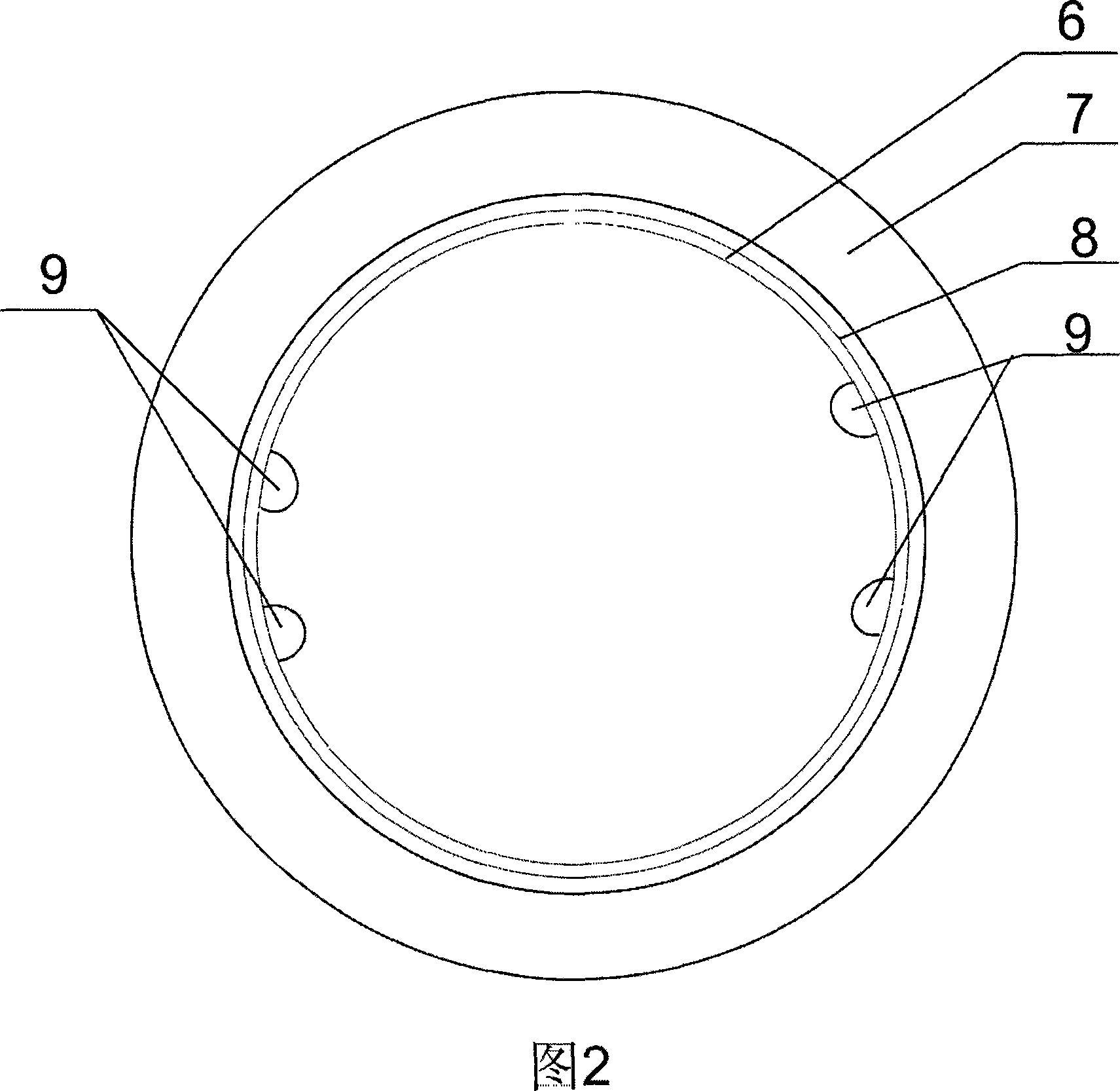

Tire molding drum

The invention provides a tire molding drum, aiming at solving the tire quality problems in the prior art that a side wall of a reversely-covered tire has too deep indentation and rubber on the side wall part is uneven after inflation. The tire molding drum comprises a main shaft, a locking block assembly and a reversely covering device, wherein the reversely covering device comprises a plurality of reversely covering rods; a reversely covering rolling wheel is arranged at the front end of each reversely covering rod; the same barrel-shaped flexible covering object sleeves the locking block assembly and the plurality of reversely covering rods of the reversely covering device on the corresponding side; the front end of the flexible covering object is fastened on the locking block assembly, and the rear end of the flexible covering object is connected onto the reversely covering device; and when the reversely covering device is reversely covered in place, the front part of the flexible covering object is completely fitted on the side wall of the tire. The flexible covering object is arranged, so that the rubber on the side wall can be prevented from being directly extruded by the reversely covering rolling wheels; and the extruding pressure of the rolling wheels is buffered, so that the extruding force on the side wall by the reversely covering rolling wheels is reduced, the indentation on the reversely-covered side wall of the tire is alleviated, and the quality of the tire is improved.

Owner:QINGDAO MESNAC ELECTROMECHANICAL ENG +1

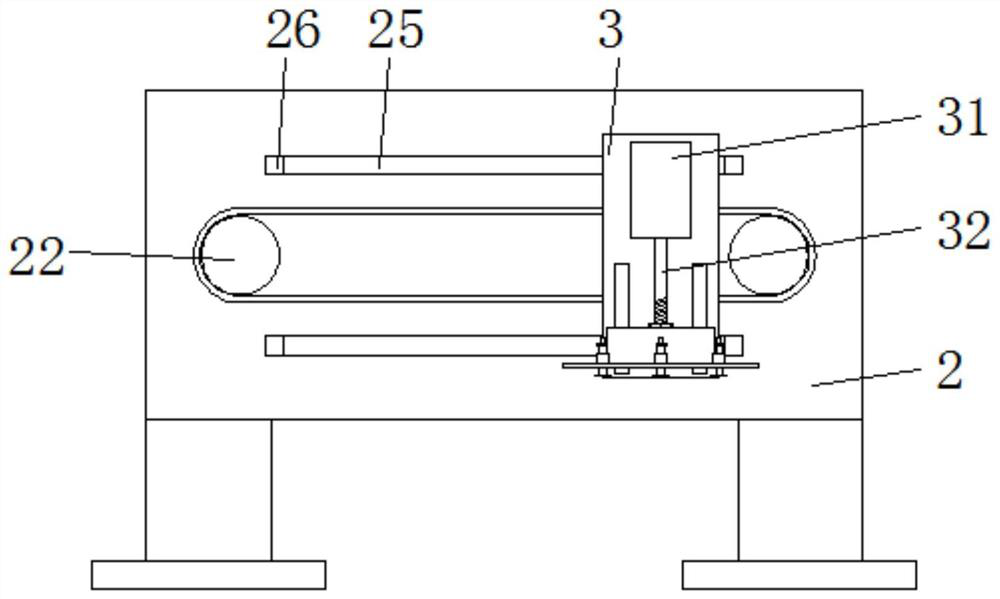

Flatness and appearance dimension testing equipment for sheet metal products

ActiveCN112229364BPrevent crushingPrevent splashMeasurement devicesTransmission beltStructural engineering

The invention discloses flatness and appearance size testing equipment of metal sheet products, comprising a testing table body, a support plate, a fixing plate, a connecting block and a connecting rod. A rotating shaft is installed symmetrically inside the support plate, a transmission wheel is installed on the outer wall of one end of the support plate through the rotating shaft, a transmission belt is sleeved on the outer wall of one side of the transmission wheel, and a fixing plate is installed on the outer wall of one side of the transmission belt. Limiting grooves are symmetrically arranged on the outer wall of one side of the plate, the outer wall of the fixing plate on the side different from the limiting groove is installed with a cylinder body, and the outer wall of the side of the fixing plate facing away from the cylinder body is arranged on the connecting block. The invention achieves the effect of protecting the product by setting the sleeve, the connecting rod and the spring, ensuring the integrity of the product, avoiding the generated debris from splashing around, causing damage to other products, ensuring the flatness of the product placement, and ensuring the detection. data accuracy.

Owner:昆山富天达金属科技有限公司

A shielding grounding structure and terminal equipment

ActiveCN110072331BReduce in quantityWill not harmPrinted circuit groundingCross-talk/noise/interference reductionMetal frameworkTerminal equipment

The invention relates to the technical field of electronic product manufacturing, and provides a shielding grounding structure and terminal equipment. The shielding grounding structure is used for electrically connecting a printed circuit board and a metal framework and comprises a shielding grounding unit, wherein the shielding grounding unit comprises a shielding cover and an elastic part, the shielding cover and the elastic part are integrally formed, the shielding cover is used for connecting the printed circuit board, and the printed circuit board is electrically connected with the metalframework by the elastic part so that the electrical conduction of the printed circuit and the metal framework is achieved. The shielding cover and the elastic part are integrally formed, thus, the elastic part can be simultaneously formed when the shielding cover is fabricated, the material number is reduced, and the fabrication cost is favorably reduced; and since the printed circuit board is electrically connected with the metal framework by the elastic part, the printed circuit board is prevented from being directly extruded during the connection process, so that no damage to the printed circuit board is generated.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

A pipe fitting clamping device for automatic machinery

ActiveCN107971795BSolve the problem of poor clamping effectAccurately achieve the processing purposeWork clamping meansPositioning apparatusPipe fittingEngineering

The invention discloses a pipe fitting clamping device for an automatic machine. The pipe fitting clamping device comprises a bottom plate, a sliding rail is arranged at the bottom of the bottom plate, and supporting plates are fixedly connected to the two sides of the top of the bottom plate; and the tops of the two supporting plates are fixedly connected through a top plate, a first sliding groove is formed in the top of the bottom plate, and a fixing block is fixedly connected to the middle point of the bottom of the inner wall of the first sliding groove. According to the pipe fitting clamping device for the automatic machine, a second sliding groove, second sliding blocks, pneumatic telescopic rods, abutting blocks, annular sleeves and second air cylinders are arranged, and the problem that the clamping effect of a common pipe fitting clamping device is not good is solved, so that the stress at each part of the pipe fitting can be reasonably distributed; and when the pipe fittingis machined, shaking of the pipe fitting caused by unstable fixing due to the fact that the tensioning force in one part of the fitting is too large or too small does not occur, so that the expected machining purpose is achieved accurately, the clamping radius is conveniently adjusted according to the diameter of a pipe, and great convenience is brought to a user.

Owner:安徽新立滤清器有限公司

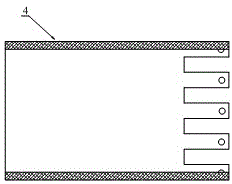

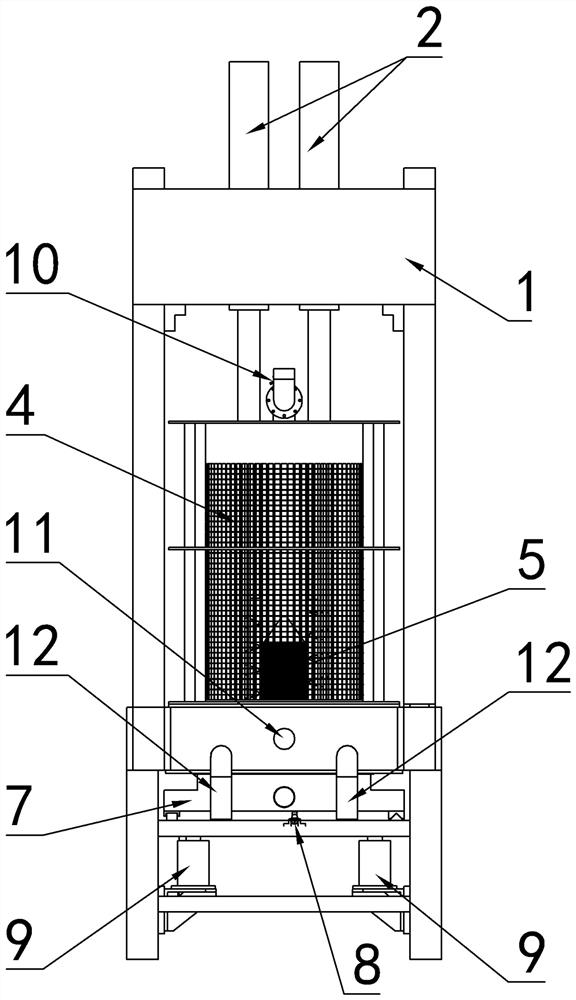

Filter press

PendingCN111905426ARealize solid-liquid separationAvoid direct extrusionMembrane filtersStationary filtering element filtersEngineeringFilter press

The invention discloses a filter press, and the filter press comprises an integral frame, a filtering mechanism and a pressing mechanism, wherein the filtering mechanism and the pressing mechanism arefixedly arranged on the integral frame; the pressing mechanism comprises a top pressing part and a bottom supporting part; the filtering mechanism is arranged between the top pressing part and the bottom supporting part, and a feeding pipeline and a water outlet pipeline are communicated with the filtering mechanism. According to the invention, the solid-liquid separation efficiency of materialsis improved, and the bearing pressure of the filter screen in the filter pressing process is reduced. The solid-liquid separator is suitable for the fields of coal mines, metallurgy, pharmacy, sewagetreatment and the like, and is used for solid-liquid separation of materials.

Owner:河北林发环保设备有限公司

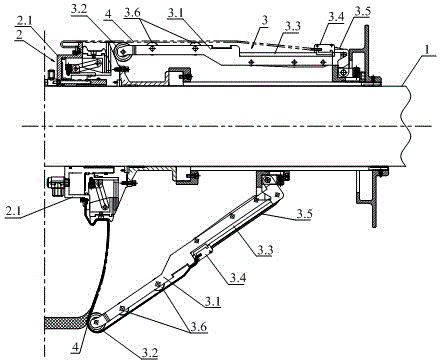

Double guide-bar telescoping mechanism for motor vehicle equipment

PendingCN110919251ASmall sizeAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

Owner:天津巴泰克汽车装备有限公司

Electronic product adjusting type storage device with fixing effect

InactiveCN108995975AAvoid direct extrusionPrevent extrusionContainers preventing decayContainers to prevent mechanical damageEngineering

Owner:黄杰琦

Placement device and operation method for tsp blast hole emulsion explosive

ActiveCN104613834BIncrease success rateImprove placement efficiencyBlastingDetonatorMeasurement device

Owner:SHANDONG UNIV

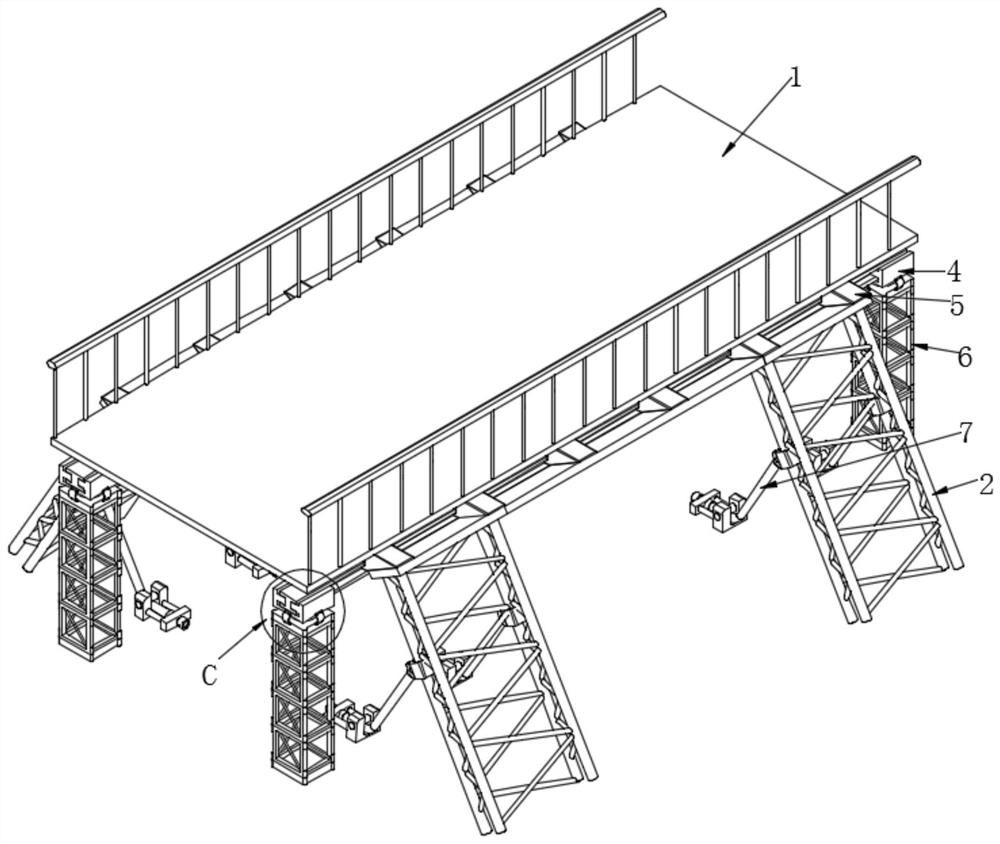

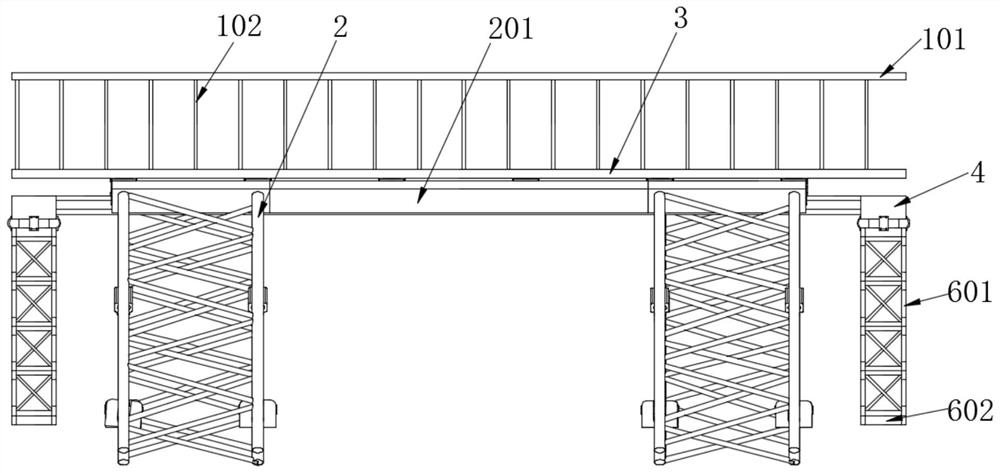

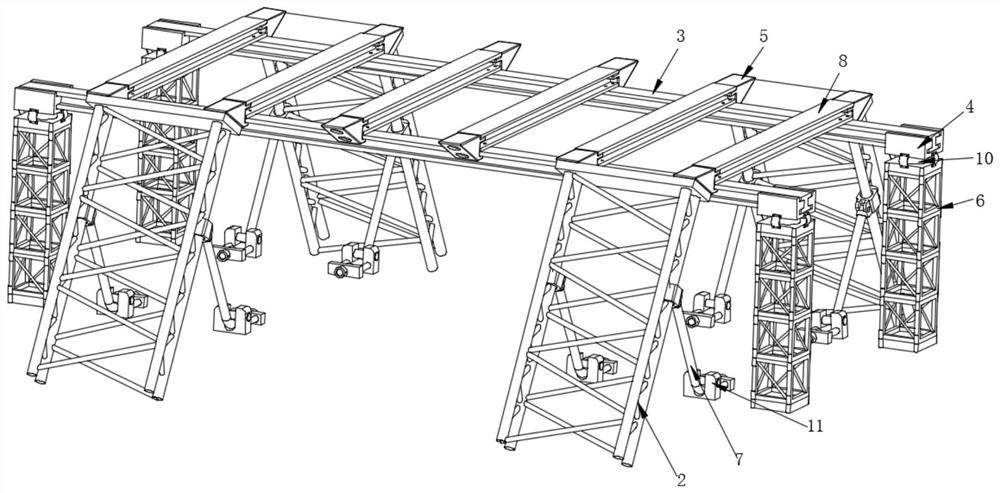

Light steel frame bridge structure and erecting method thereof

InactiveCN113152241AReduce the difficulty of erectionAvoid direct extrusionBridge structural detailsBridge erection/assemblyArchitectural engineeringBridge deck

The invention discloses a light steel frame bridge structure and an erecting method thereof. The light steel frame bridge structure comprises a bridge floor, inclined supporting units and bridge piers. Main I-shaped steel is installed on the two sides of the bottom of the bridge floor, shock absorbers are installed at the bottoms of the two ends of the main I-shaped steel, bridge piers are arranged at the bottoms of the shock absorbers, inclined supporting units are installed at the two ends of the main I-shaped steel, and tensioning steel ropes are installed on the two sides of each inclined supporting unit; the end, away from the inclined supporting unit, of the tensioning steel rope is connected with a U-shaped tensioning foundation anchor. The main I-shaped steel and the auxiliary I-shaped steel are staggered to construct the bridge deck structure, then the four sets of inclined supporting units are obliquely installed at the bottom of the bridge deck structure, the inclined supporting units share the load of the bridge pier structure, a steel frame supporting structure is adopted to replace a zipper structure, the erecting difficulty is reduced, and through combined use of the tensioning ropes and the inclined supporting units, the damping effect of the bridge is improved, the bridge bearing structure is connected in a split mode, and it is guaranteed that the bridge steel structure cannot lose efficacy when used for a long time.

Owner:闫军涛

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com