Placing device for TSP blast hole emulsion explosive and operation method

An emulsion explosive and blast hole technology, applied in blasting and other directions, can solve the problems of accurate judgment affecting the stability of the surrounding rock of the front face, the crushed stone damage of the hole wall of the electronic detonator detonator, and the difficulty of the explosive card reaching the standard depth, etc. Achieve the effect of improving placement efficiency, humanized design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

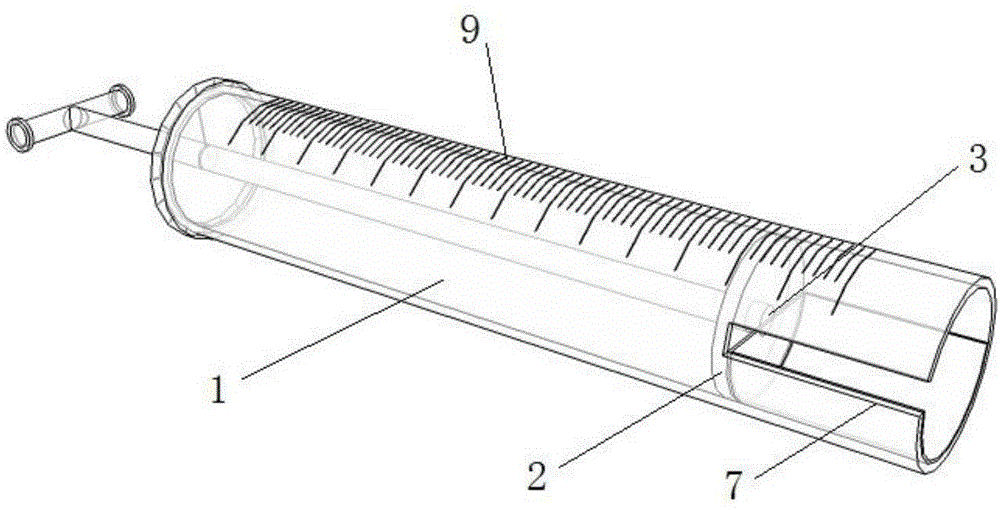

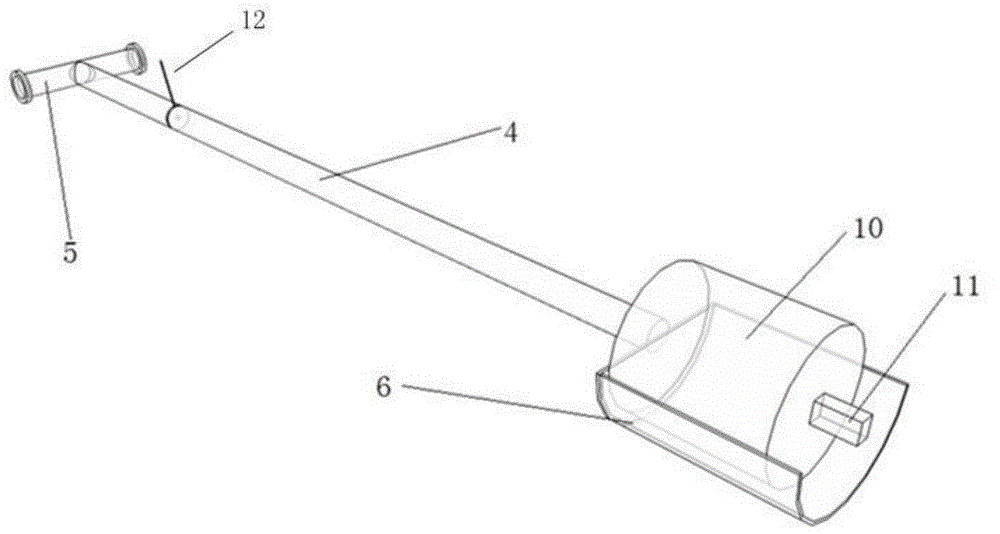

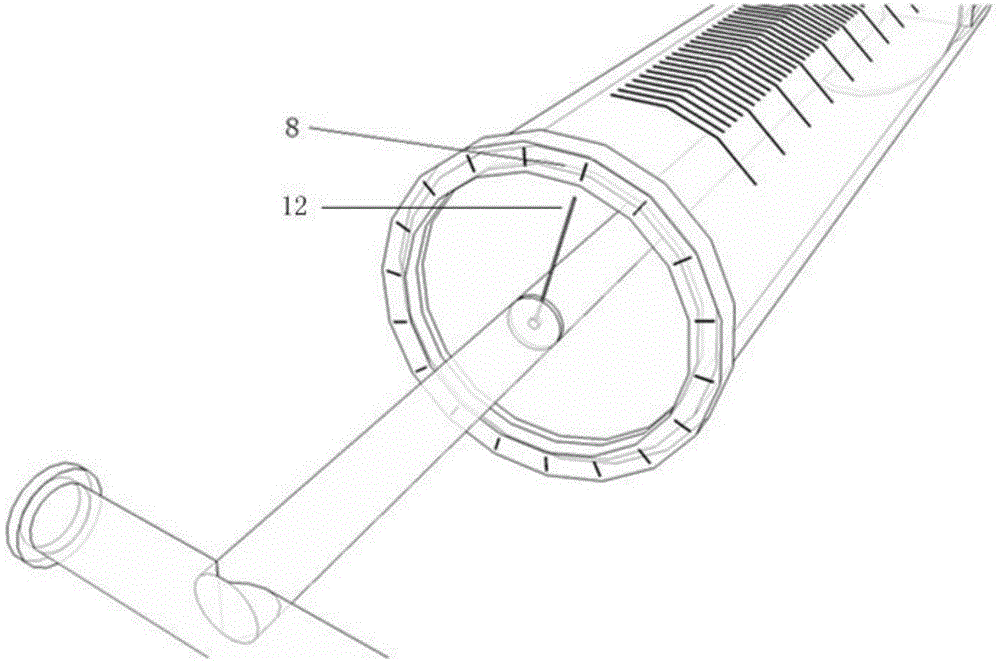

[0030] The placement device for TSP blasthole emulsion explosives includes a stainless steel protective sleeve 1, inside which is fixed a separator 2 in the cylinder, with a sleeve opening groove 7 at the front end, and a separator hole 3 in the cylinder inner separator 2 for the purpose of The core connecting rod 4 passes through, and the two ends of the barrel core connecting rod 4 are respectively connected to the explosive placement bucket 6 and the rotating hand lever 5, and the three are consolidated into one; the depth of entering the blast hole is adjusted by pumping the barrel core connecting rod 4, and the depth can be determined by Measured by the scale 9; the pointer 12 and the angle scale 8 form an angle measuring device together, which can measure the rotation angle of the rotating hand lever 5.

[0031] The stainless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com