Device for automatically wrapping transformer cables with crepe paper

A transformer cable and crepe paper technology, applied in the manufacture of inductors/transformers/magnets, insulating conductors/cables, circuits, etc., can solve the problems that the movement is not uniform, affects the insulation strength and aesthetics of the product, and the difference will be very obvious. , to achieve the effect of precise control and intelligent wrapping of crepe paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

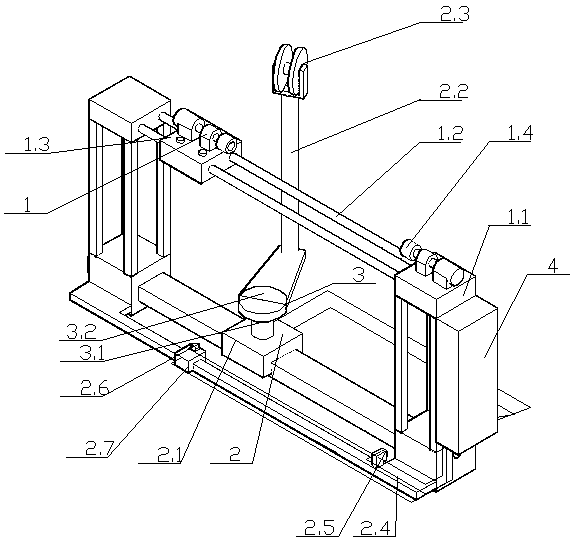

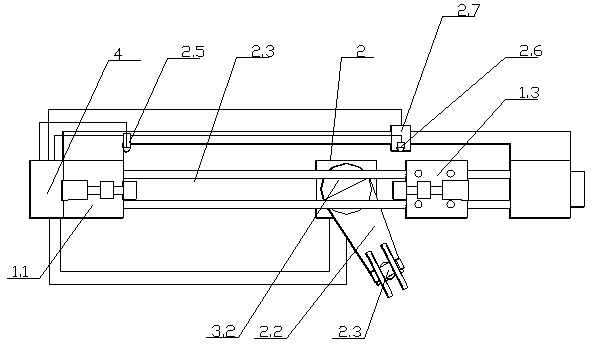

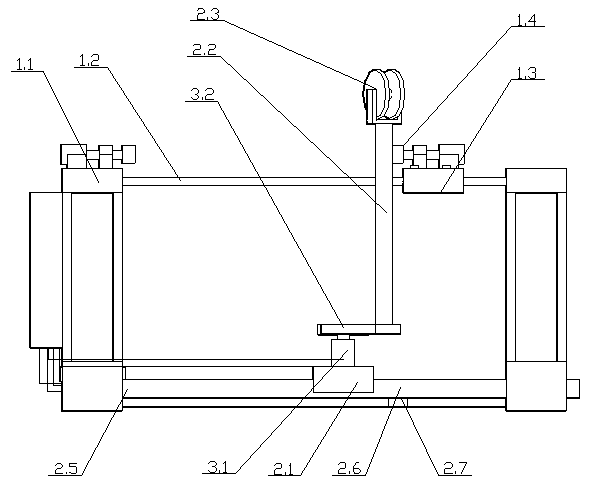

[0015] Now in conjunction with accompanying drawing, the present invention is further elaborated.

[0016] Such as Figure 1-6 As shown, a device for automatically wrapping crepe paper on transformer cables, including cable clamping mechanism 1, crepe paper roll 2.3 moving mechanism 2 and crepe paper roll steering mechanism 3, wherein cable clamping mechanism 1 fixing seat 1.1, sliding track 1.2. The sliding seat 1.3 and the gripping head 1.4, wherein there are two fixed seats 1.1 and the two fixed seats 1.1 are fixed on the ground by embedded bolts. There is a distance between the two fixed seats 1.1. A sliding track 1.2 is arranged between the seats 1.1, and the two ends of the sliding track 1.2 are respectively connected with two fixed seats 1.1 by welding, and a fixed sliding seat 1.3 is arranged on the sliding track 1.2 (there are openings on the sliding seat 1.3 The hole matched with the sliding track 1.2, the sliding seat 1.3 is matched with the sliding track 1.2 as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com