A kind of riveting method of balance counterweight and riveting tooling

A technology of balancing counterweight and riveting tooling, applied in the field of mechanical assembly, can solve the problems of unstable riveting process, easy riveting failure, fatigue stress of fan disk, etc., and achieve the effect of improving the success rate of riveting, shortening the assembly cycle and good positioning performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is described in further detail below in conjunction with accompanying drawing:

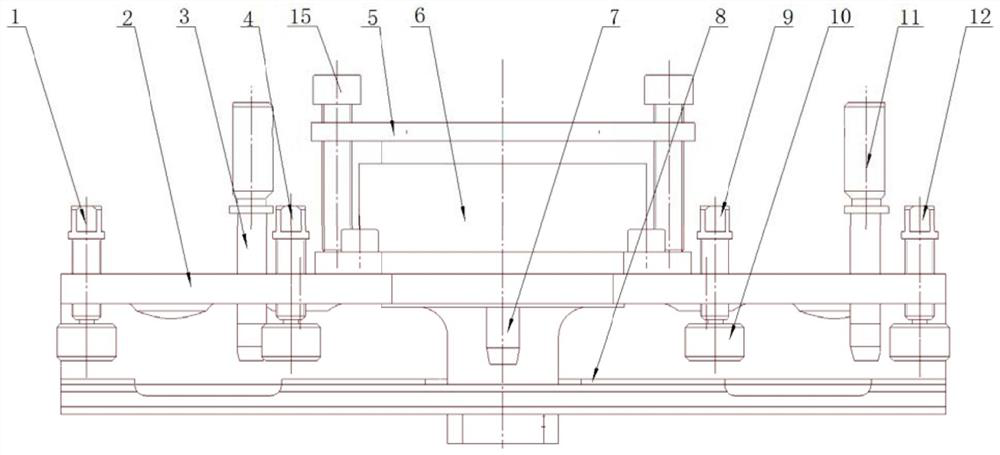

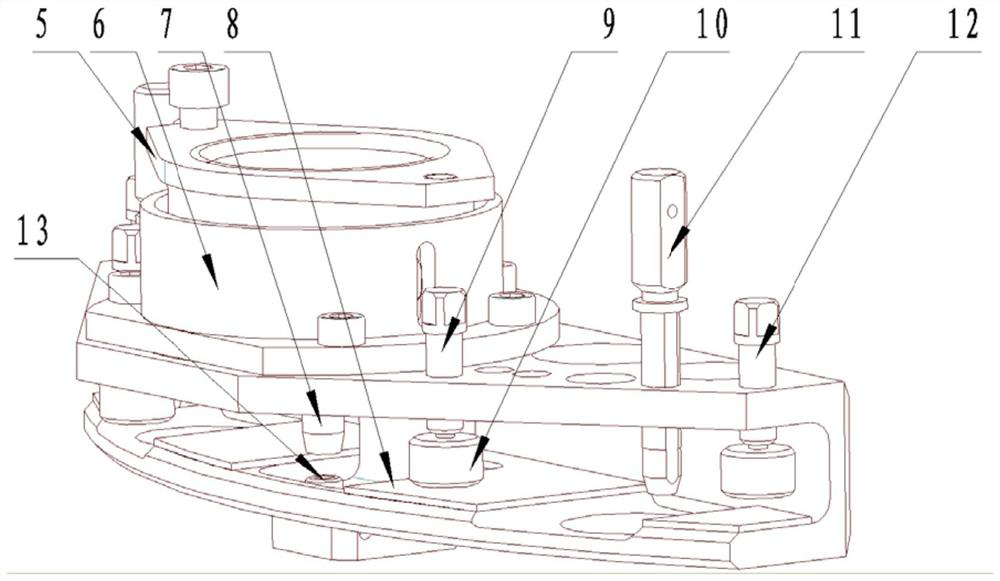

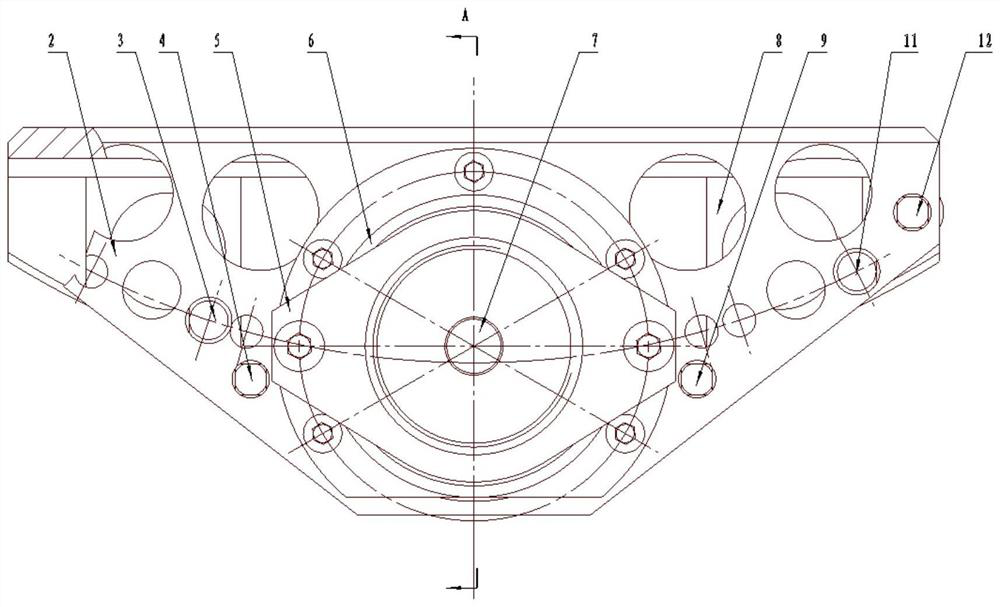

[0039] Such as Figure 1 to Figure 4 As shown, a balance weight riveting tooling includes a bow-shaped clamp block 2. The U-shaped groove structure in the middle of the bow-shaped clamp block 2 matches the front surface of the fan disk. The two sides of the bow-shaped clamp block 2 are the upper end wall and the lower end wall respectively. The upper end wall of the clamp block 2 is provided with a through hole perpendicular to the upper end wall, and the upper side of the upper end wall of the bow-shaped clamp block 2 is fixed with a positioning block 6. The through hole on the block 2 is coaxial, and the pressure seat mounting hole of the positioning block 6 is provided with a pressure mounting seat 5, and the pressure mounting seat 5 is provided with a pressure device mounting hole, and the pressure device is threadedly connected with the pressure device mounting ho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap