Nail outlet mechanism of pneumatic nail gun

A nail gun and pneumatic technology, applied in the field of the nail ejecting mechanism of the pneumatic nail gun, can solve the problems of poor stability and complex structure, and achieve the effects of high stability and improved positioning stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

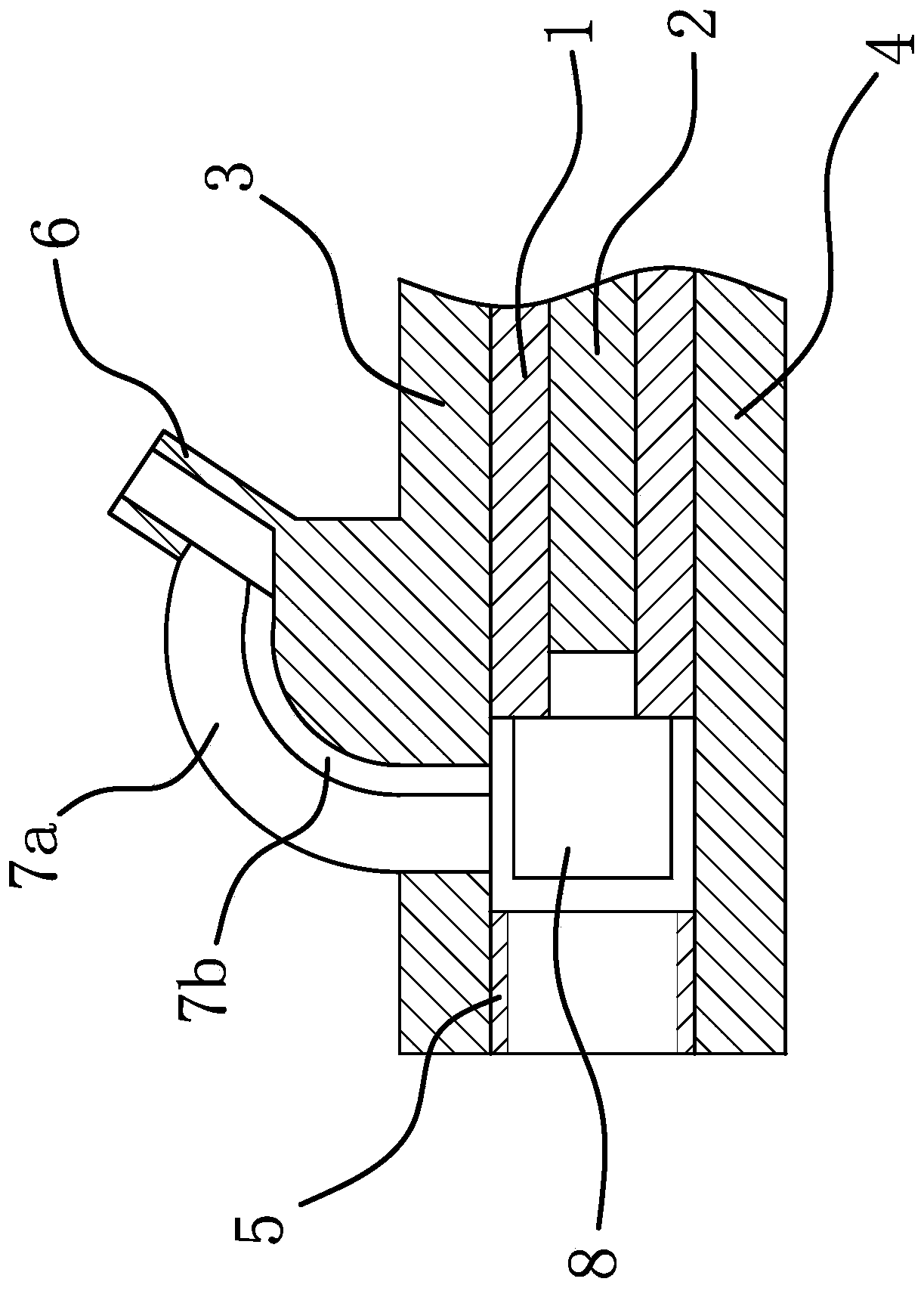

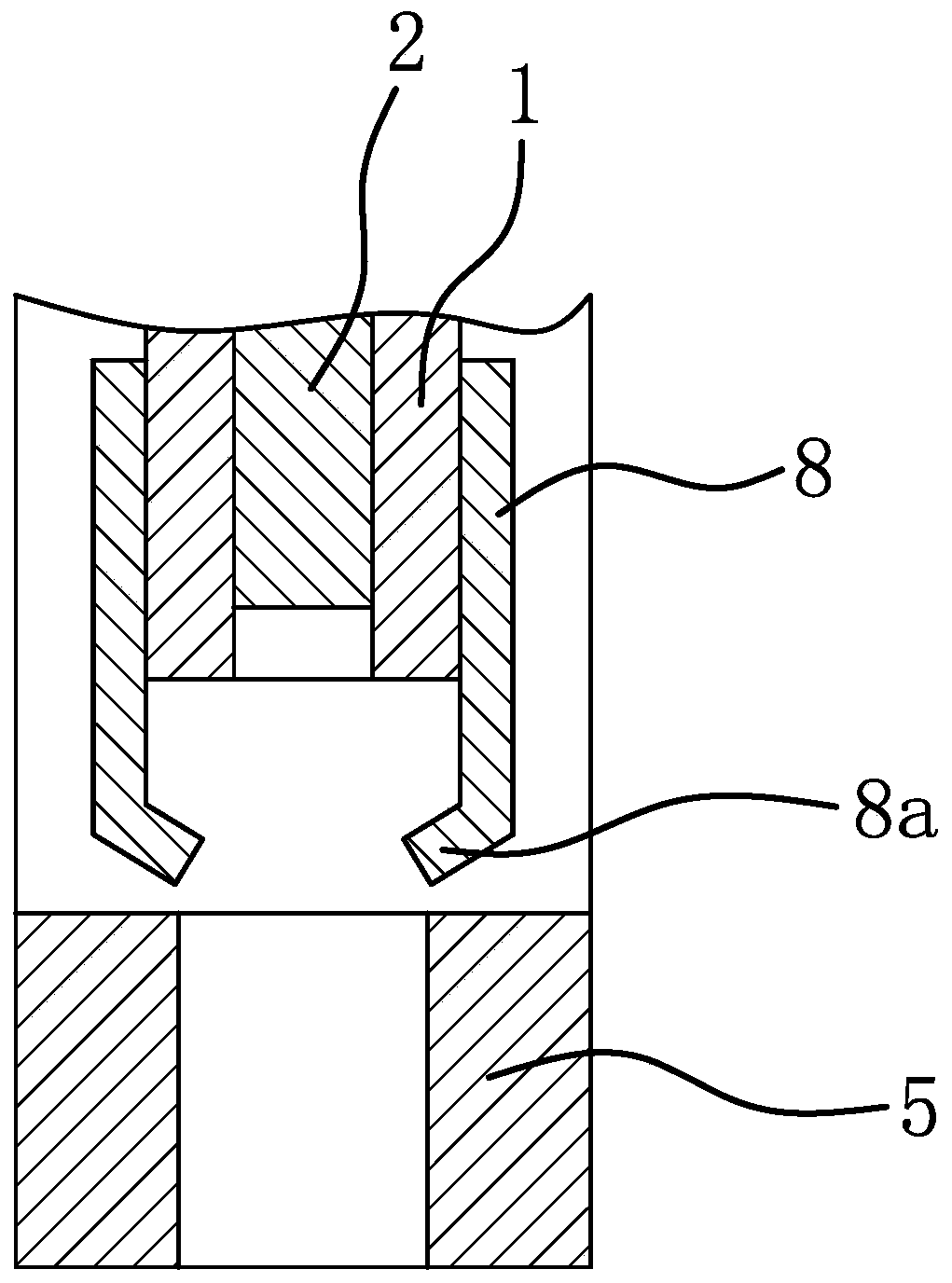

[0037] Such as figure 1 and figure 2 and Figure 4 As shown, the pneumatic nail gun includes a gun body. The nail output mechanism of the pneumatic nail gun includes a pre-positioning cylinder 1, a striker 2, a feed channel and a pre-positioning part. The interior of the above-mentioned gun body is a cavity and the above-mentioned pre-positioning cylinder is located in the gun body , the above-mentioned striker 2 is located in the pre-positioning cylinder 1, the end of the gun body is a nail outlet connected to the inner cavity, the above-mentioned feeding channel is located on the upper part of the gun body, and one end of the feeding channel is for nails to enter the feeding port, and the gun body The cavity between the upper outlet and the pre-positioning cylinder communicates with the other end of the above-mentioned feeding channel, the above-mentioned pre-positioning part is fixedly connected to the gun body, and the nails input into the gun body at the above-mentioned...

Embodiment 2

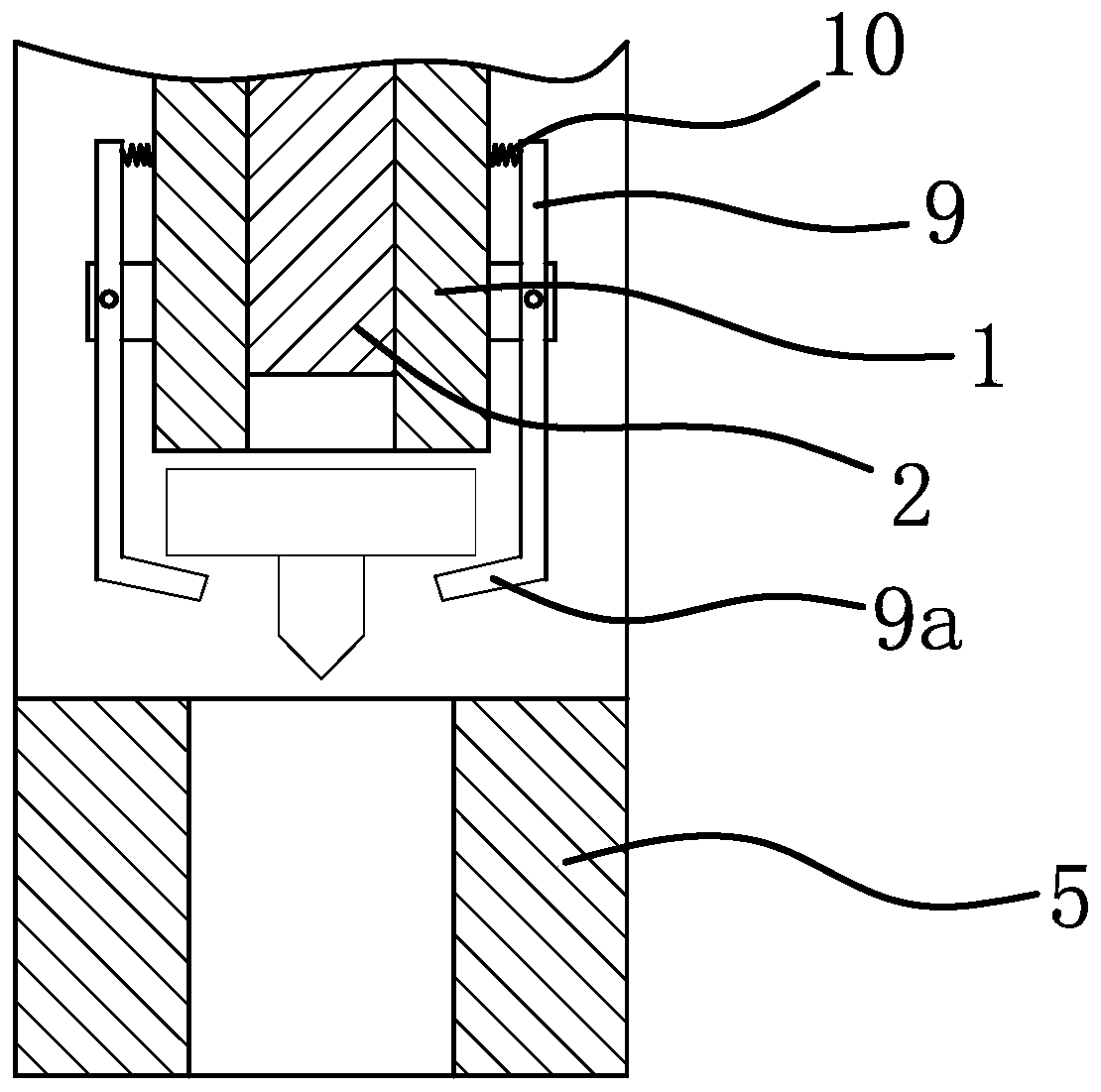

[0049] Such as image 3 As shown, the pre-positioning part includes a compression rod 9 and a spring 10, the middle part of the above-mentioned compression rod 9 is hinged on the plate body two 4, and there is a spring 10 between the compression rod 9 inner end and the plate body two 4, and the elastic force of the spring 10 The outer end of the pressing rod 9 has a tendency to be close to the pre-positioning cylinder 1 under action.

[0050] The outer end of the pressing rod 9 has a bent positioning section 9a, and a positioning portion for positioning the nail head is formed between the positioning section 9a and the pre-positioning cylinder 1 .

[0051] The pressing rod 9 and the spring 10 form a pre-positioning unit, the number of the pre-positioning units is two and the two pre-positioning units are symmetrically distributed on both sides of the pre-positioning cylinder 1 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap