a stamping machine

A stamping machine, a pair of technology, applied in the field of stamping machines, to achieve the effect of ensuring clarity, improving stamping efficiency, and reducing labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below.

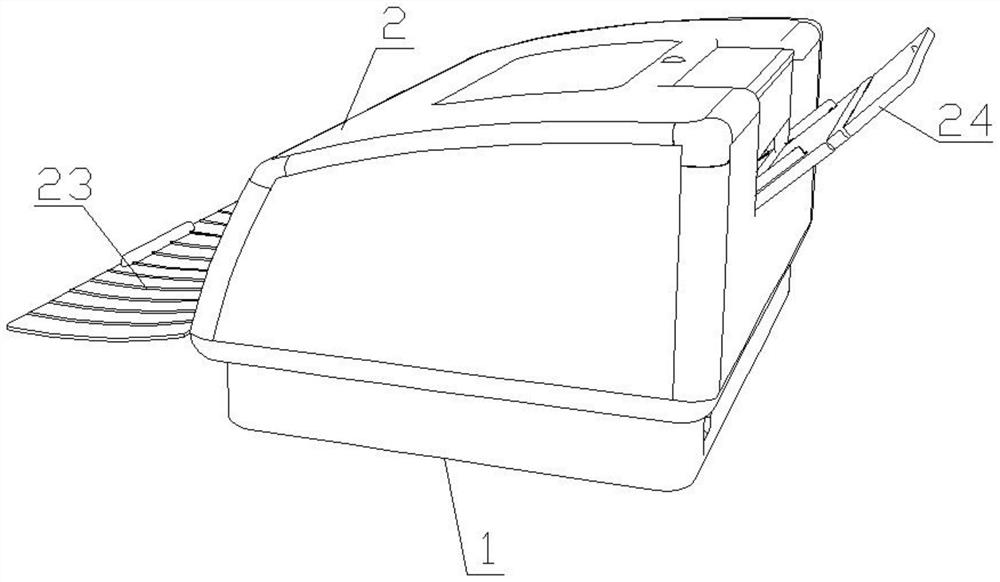

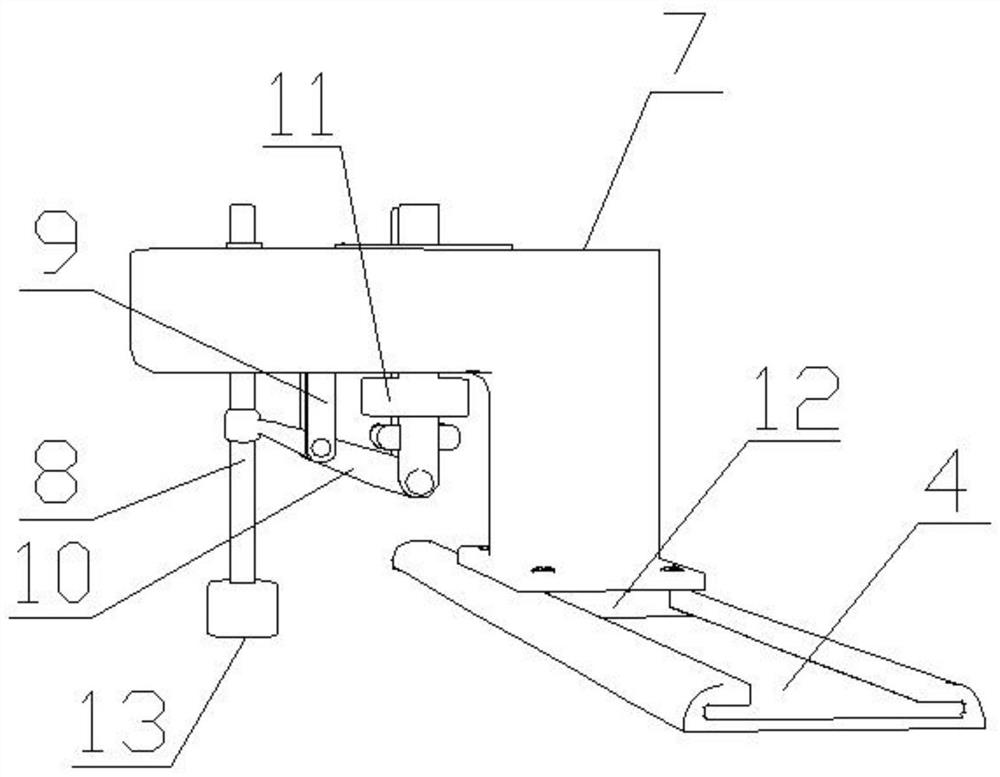

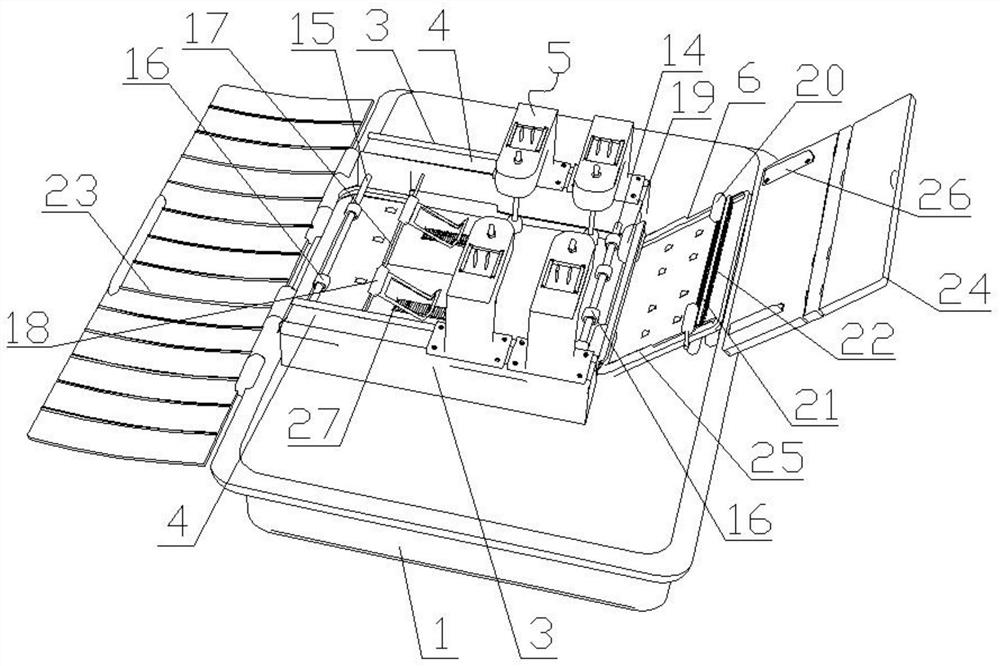

[0024] Such as Figure 1 to Figure 3 As shown, a stamping machine includes a base 1 and a machine case 2 fixedly connected to the top of the base 1, the machine case 2 is composed of a bottom plate and a cover body; A paper outlet, the bottom of the other end is provided with a paper outlet; a controller is also included; a pair of support rails 3 are arranged parallel to the top of the bottom plate of the machine housing 2, and a paper passage is formed at the bottom between the pair of support rails 3; A pair of slide grooves 4 are arranged in parallel on the upper end faces of a pair of supporting rails 3; two stamping mechanisms 5 are arranged on each supporting rail 3;

[0025] The bottom plate of the machine casing 2 is provided with an inclined support plate 6 on one side of the paper inlet, the upper end of the inclined support plate 6 communicates with the paper inlet, and its lower end extends to the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com