Assembly type prestressed highway tunnel crash barrier

A technology for anti-collision guardrails and road tunnels, which is applied in the direction of roads, roads, road safety devices, etc., and can solve problems such as difficult replacement, poor durability of seams, dislocation of the top surface of guardrail assembly, etc., to achieve easy replacement, good protection, and reduce The effect of casualties and economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

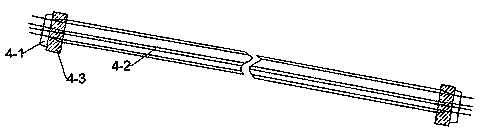

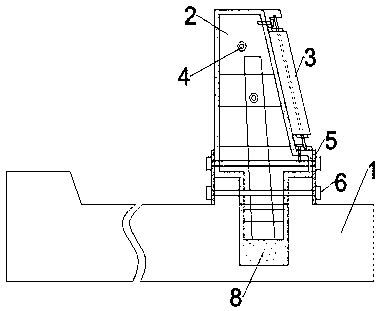

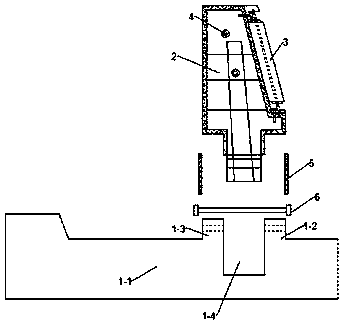

[0034] Embodiment: An assembled prestressed highway tunnel anti-collision barrier, including highway foundation 1, anti-collision barrier 2, anti-collision roller 3, prestressed rigging 4, bottom sleeve 5, connecting bolt 6, roller fixing part 7, Concrete pouring belt 8, expansion bolt 9;

[0035] The anti-collision guardrail 2 is composed of a prefabricated guardrail main body 2-1, a horizontally stressed steel bar 2-2, a vertically stressed steel bar 2-3, a transversely stressed shear steel bar 2-4, a bottom mounting tenon 2-5, an outer Stretching steel cage 2-6, drum installation platform 2-7, cableway 2-8 consists of eight parts;

[0036] The prefabricated guardrail main body 2-1 is internally arranged with horizontally stressed steel bars 2-2, vertically stressed steel bars 2-3 and transversely stressed shear steel bars 2-4; At the bottom, the horizontal stress reinforcement 2-2 and the vertical stress reinforcement 2-3 are installed at the bottom with tenons 2-5 to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com