Main bar connection device of fabricated steel-mixed construction part

A connecting device and assembled technology, which is applied in the direction of building components, building structures, structural elements, etc., can solve the problems of non-use, construction workers have high requirements, and affect the effect of connecting upper and lower steel bars, so as to achieve high connection strength, The effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

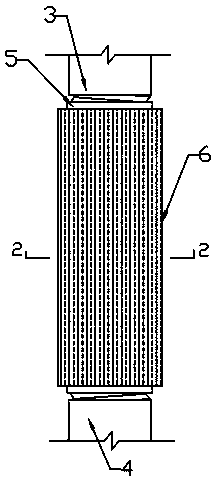

[0034] The main reinforcement connecting device of the prefabricated steel-concrete structure provided in this embodiment can be applied to prefabricated shear walls, columns and beams. Such as Figure 1-Figure 8 As shown, taking the prefabricated shear wall as an example, the existing shear wall is mainly composed of an upper shear wall and a lower shear wall. For vertical steel bars and lower vertical steel bars, a plurality of reserved blind holes corresponding to the upper vertical steel bars are arranged in the upper shear wall, and at the lower end of each upper vertical steel bar and each lower vertical steel bar The upper end is provided with a section of prefabricated threads of the same specification; each reserved blind hole is provided with a connection for connecting each two corresponding upper vertical steel bars and lower vertical bars in the upper shear wall and lower shear wall. To the steel bar, and after the upper vertical steel bar 3 and the lower vertica...

Embodiment 2

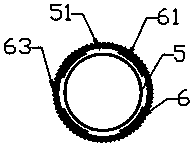

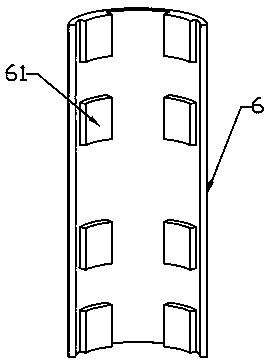

[0042] This embodiment discloses a main reinforcement connecting device of a prefabricated steel-concrete structure, which is mainly used in the assembly of main reinforcement of prefabricated beams, including an outer sleeve 6 and two outer walls and the outer sleeve 6 The inner wall is matched, and the inner wall is respectively used for the inner sleeve 5 that is threadedly connected with the two vertical main bars in the steel-concrete structure; There are differences, the specific difference lies in the shape and length of the inner protrusion 61 and the outer protrusion 51 and the axial length of the locking groove 52, and the rest are completely the same. Such as Figure 10 , Figure 11 As shown, the outer wall of each inner sleeve 5 in this embodiment is provided with four rows of outer clamping parts at axial intervals, and each row of outer clamping parts is composed of two outer protrusions 51 arranged at intervals. The size and shape of the protrusions 51 are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com