Prefabricated eddy current damping wall

A technology of eddy current damping and prefabrication, which is applied in the direction of protective buildings/shelters, building types, buildings, etc., can solve the problems of unable to assemble normally in construction, save manpower and material resources, ensure construction quality, and reduce dynamic effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention provides a prefabricated assembled eddy current damping wall.

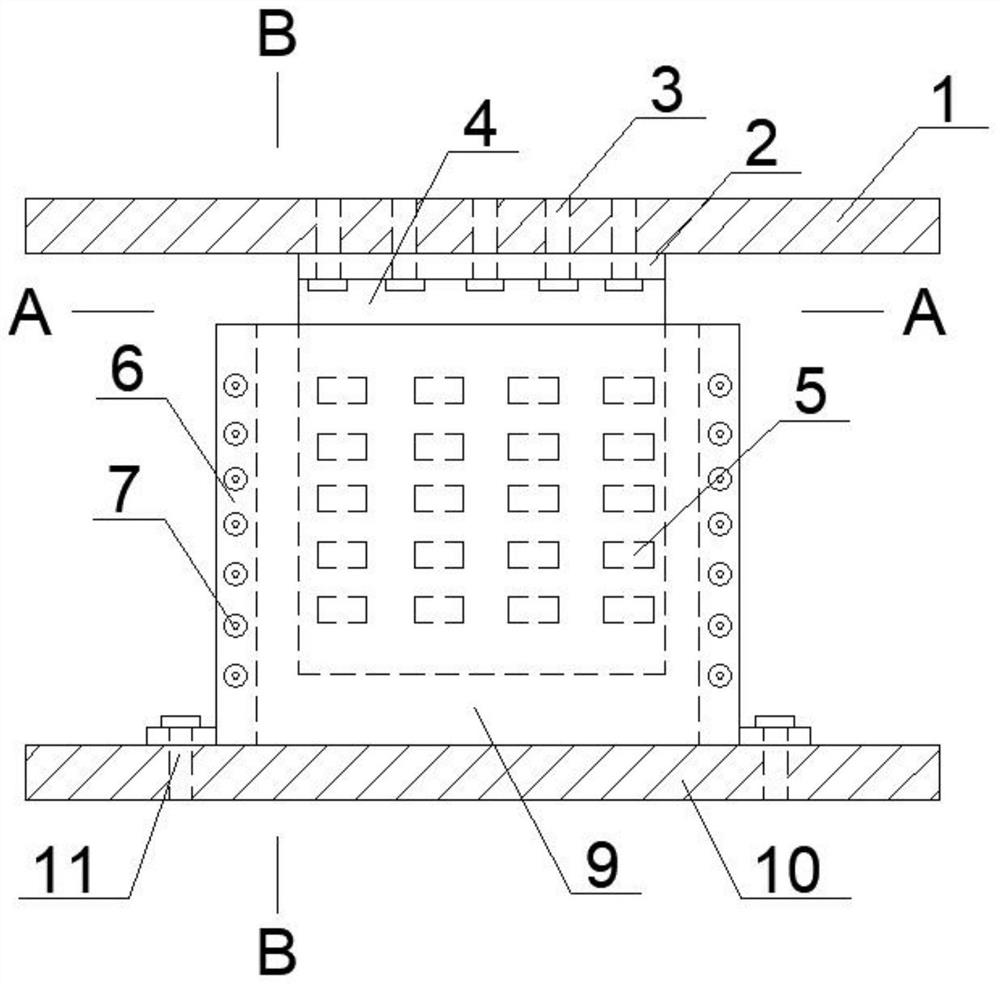

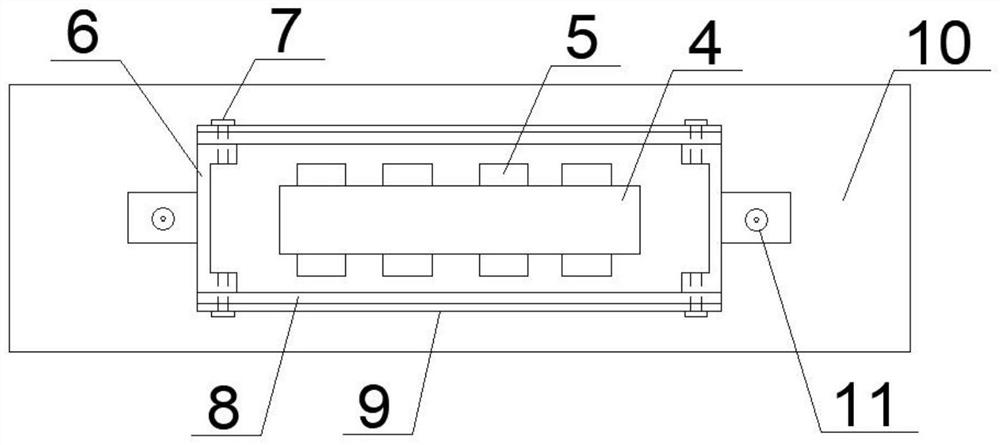

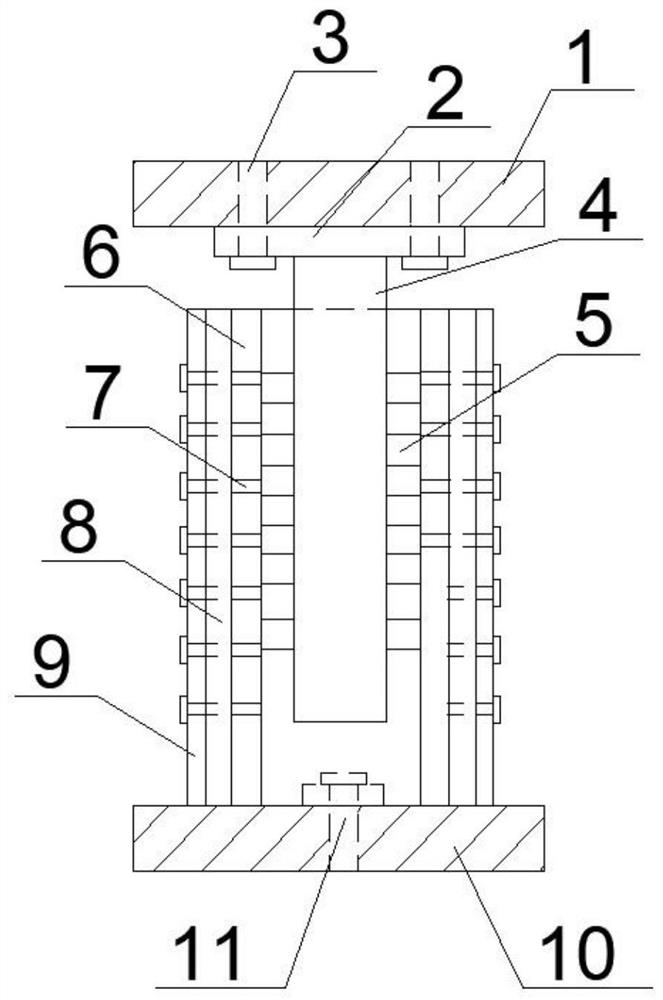

[0023] Such as Figure 1 to Figure 3 As shown, the prefabricated eddy current damping wall of the present invention consists of a top embedded steel plate 1, a damping wall top plate 2, a top bolt 3, a main steel plate 4, a permanent magnet 5, a lateral steel plate 6, a lateral bolt 7, and a conductor plate 8 , Magnetic steel plate 9, bottom embedded steel plate 10 and bottom bolt 11 are formed. Among them, the top plate 2 of the damping wall is connected to the top embedded steel plate 1 through the top bolt 3, the main steel plate 4 is connected to the top plate 2 of the damping wall through the top bolt 3, the permanent magnets 5 are evenly distributed on the main steel plate 4, and the two sides of the main steel plate 4 are arranged symmetrically The conductor plate 8 and the magnetically permeable steel plate 9 are symmetrically arranged on both sides of the conductor plate 8. The later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com