Organic light-emitting display panel, manufacturing method thereof, display device and mask

A light-emitting display and mask technology, applied in organic light-emitting devices, organic light-emitting device structures, vacuum evaporation coating, etc., can solve problems affecting the display effect of organic light-emitting display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

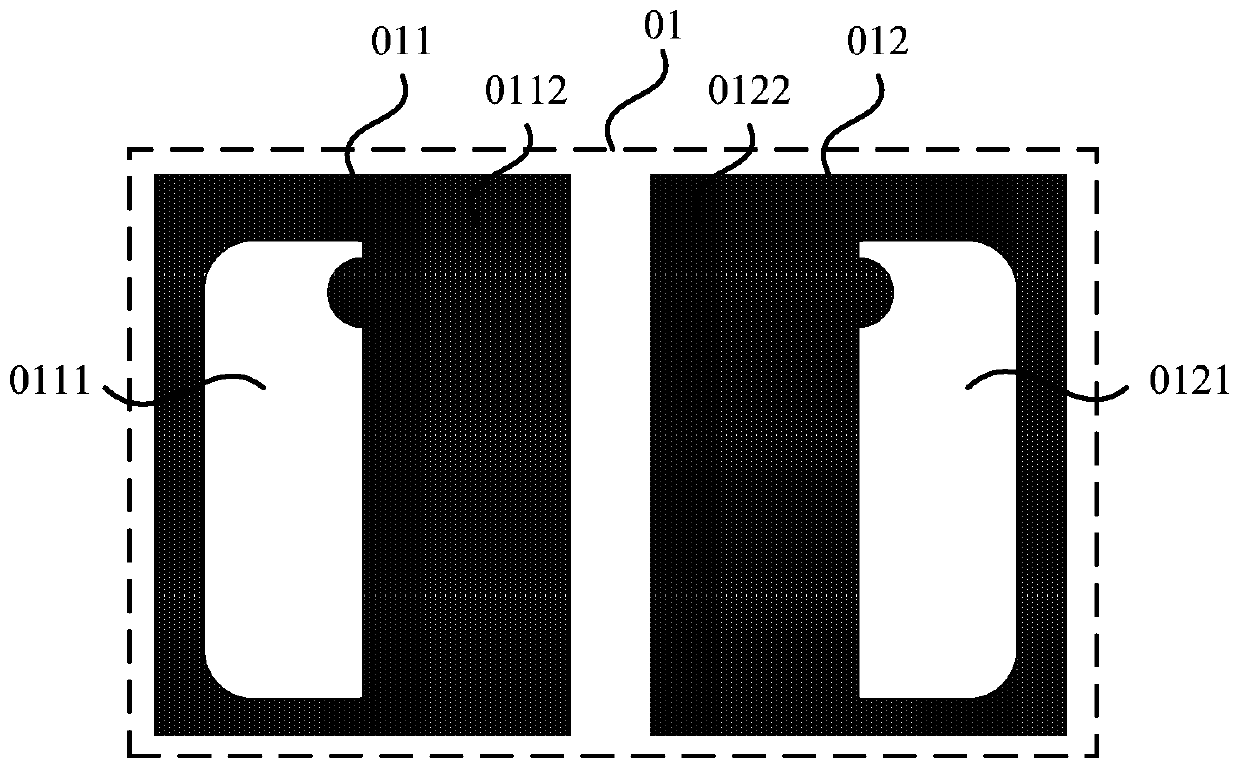

[0039] figure 1 For a structural schematic diagram of a mask plate provided for a prior art, please refer to figure 1 , the reticle 01 includes a first splicing mask 011 and a second splicing mask 012 . The first stitching mask 011 includes a first film-forming region 0111 and a first shielding region 0112 , and the second stitching mask 012 includes a second film-forming region 0121 and a second shielding region 0122 . When using the first stitching mask 011 to vapor-deposit the cathode 110 of the organic light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com