Battery module structure applicable to various integration modes

A battery module and concave-convex structure technology, which is applied to battery pack parts, batteries, structural parts, etc., can solve the problems of space occupation, low battery assembly integration efficiency, and large installation workload, etc. The effect of complex processing difficulty and reduced integration difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

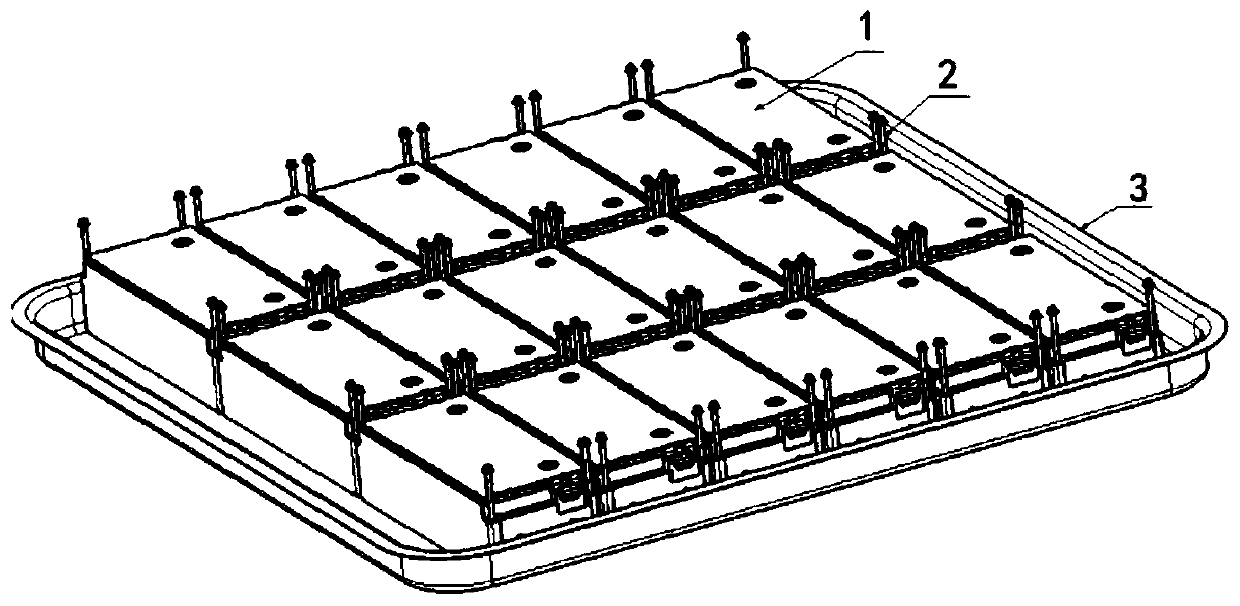

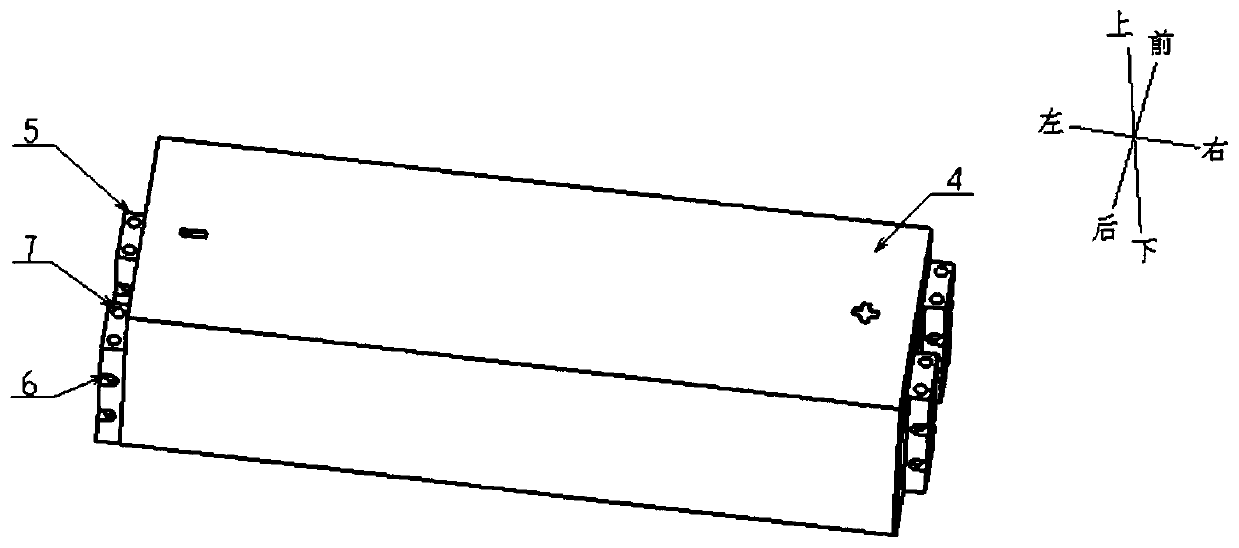

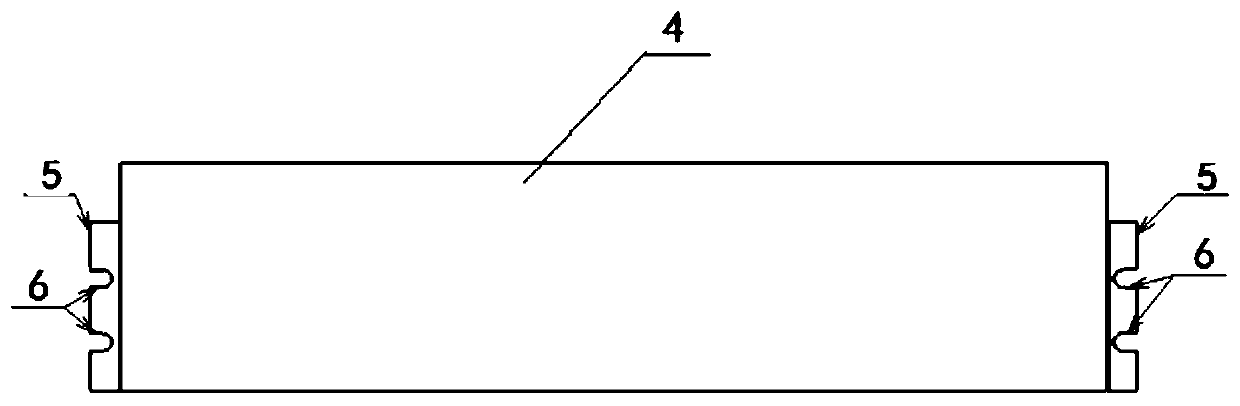

[0029] see Figure 2 to Figure 11 The shown battery module structure is suitable for various integration methods, including a plurality of rectangular parallelepiped battery modules 4, and the battery module 4 is a first battery module 41 or a second battery module with the same structure. Group 42, characterized by:

[0030] The two ends of the battery module 4 are respectively provided with a concave-convex structure 5, and the concave-convex structure 5 is formed by connecting a convex part and a concave part; The concave-convex structure 5 at one end of the negative electrode of the battery module 4 is misaligned to form a mortise-tenon connection; the positive and negative electrodes of multiple battery modules 4 are connected to form a row of battery packs, and multiple rows of battery packs are connected together through long screws 9 . Constitute a battery mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com