Pneumatic tire

A technology of pneumatic tires and tires, which is applied to special tires, tire parts, tire treads/tread patterns, etc., can solve problems such as deterioration of driving stability, achieve excellent performance on ice, and suppress the effect of curing over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

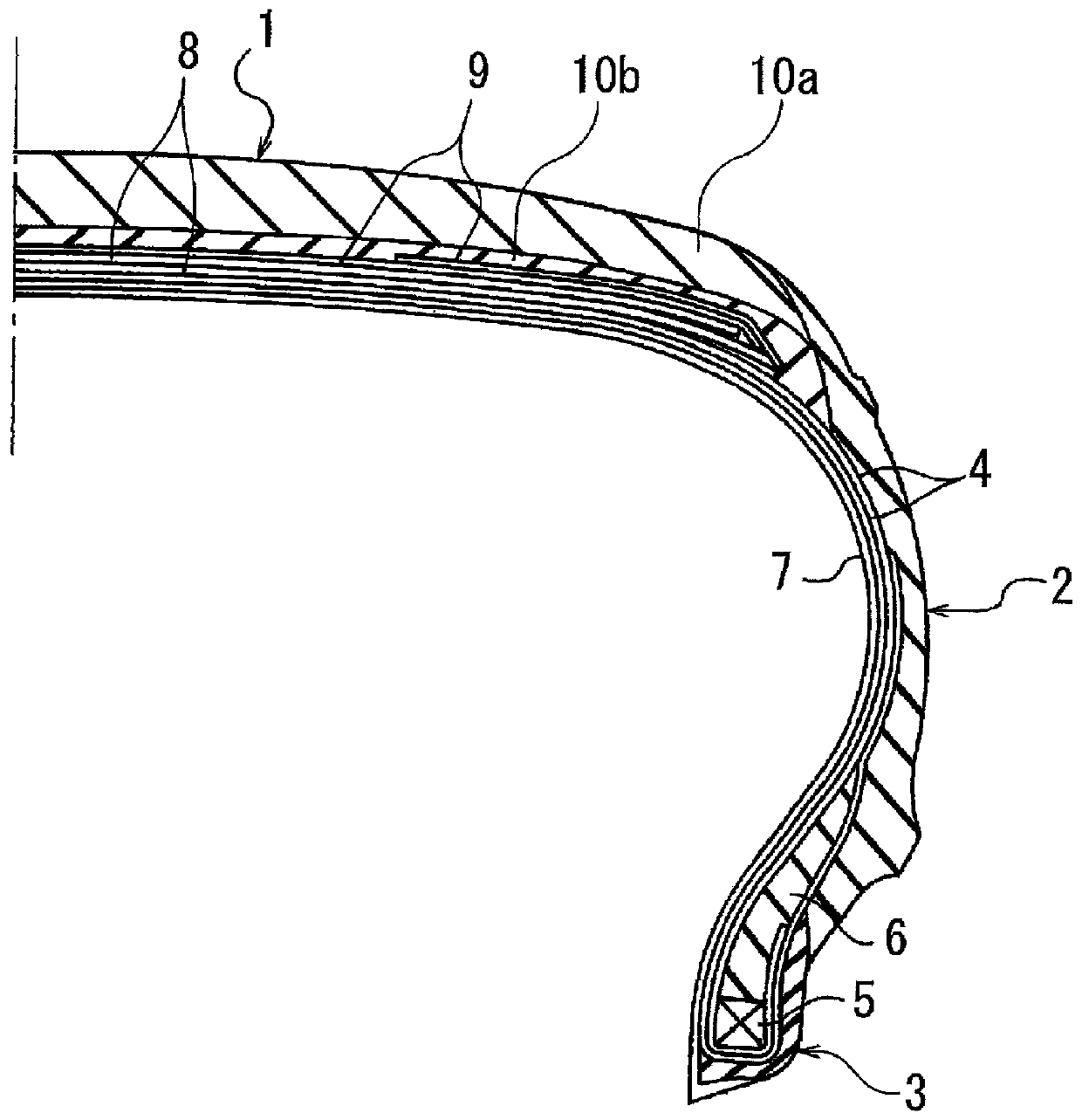

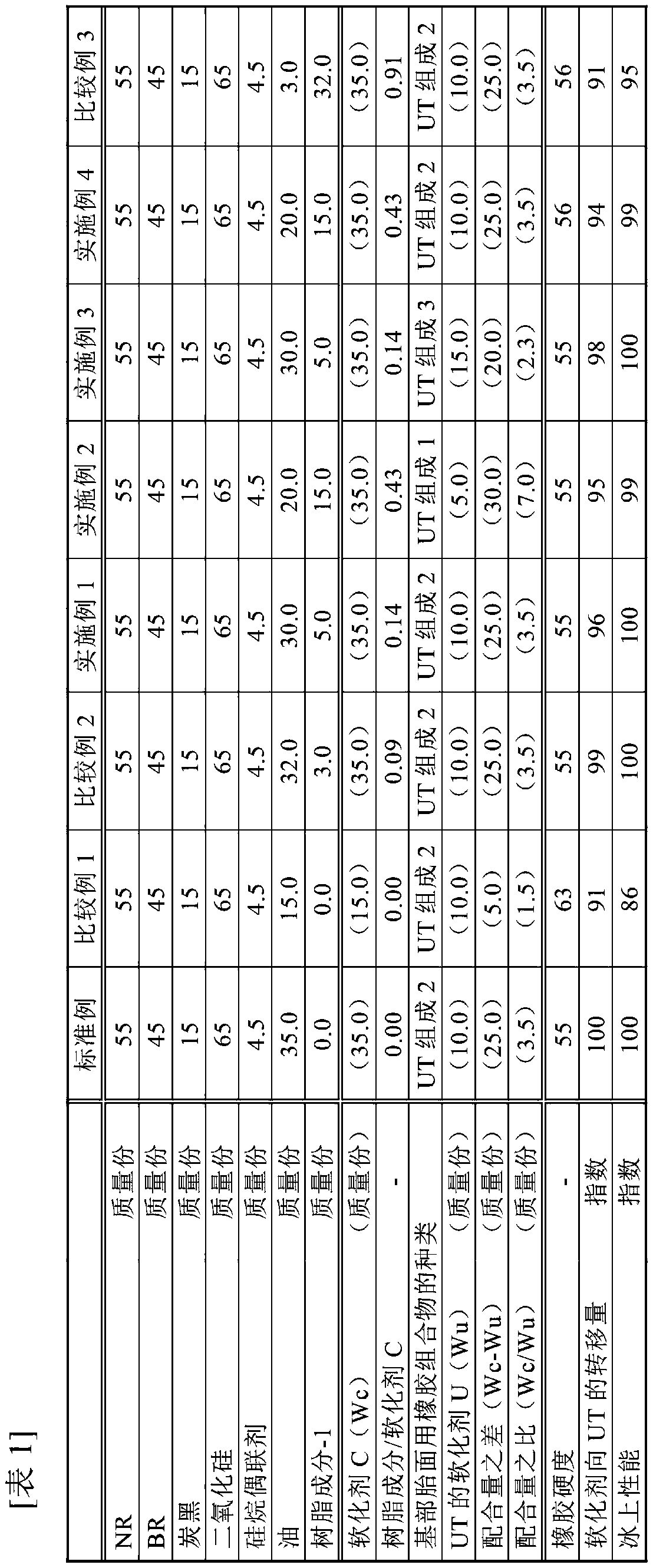

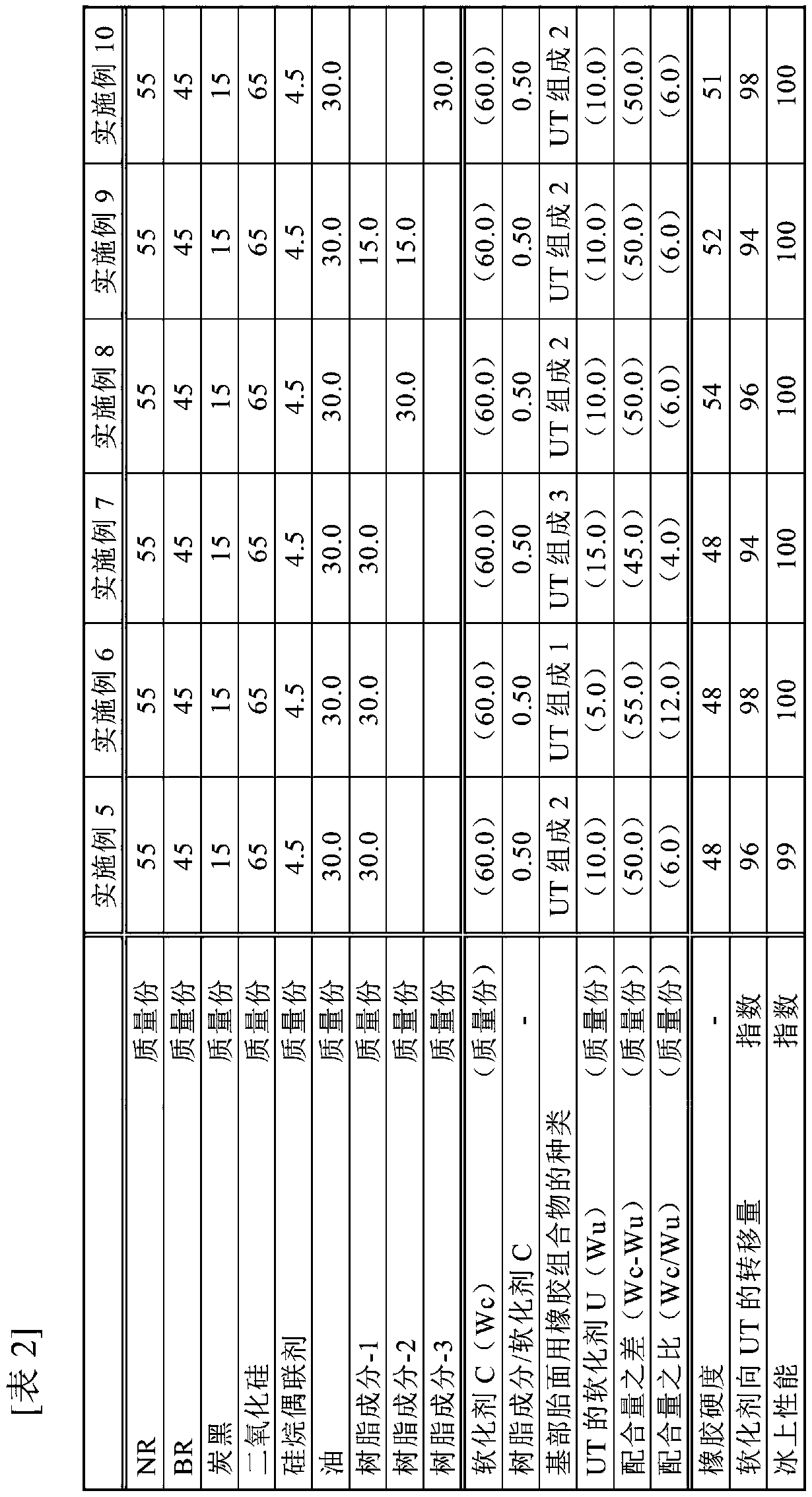

[0045] Manufacture the following pneumatic tires (size 195 / 65R15): by having the common formula shown in Table 4, containing 21 kinds of tire cap rubber compositions (embodiments 1-14, standard example, comparison Examples 1 to 6) were used to form the crown, and the base tread was formed from the three types of rubber compositions for the base tread shown in Table 5 (UT composition 1 to UT composition 3). When preparing each rubber composition, components other than sulfur and vulcanization accelerator were weighed, and after kneading for 5 minutes by a 1.7L closed-type Banbury mixer, the masterbatch was discharged and cooled at room temperature. The masterbatch was sent into a 1.7L closed-type Banbury internal mixer, sulfur and a vulcanization accelerator were added, and mixed to obtain various rubber compositions. Table 4 describes the compounding amount (parts by mass) of each compounding agent with respect to 100 parts by mass of the diene rubbers described in Tables 1 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com