Carpet surface replacement type assembled ground mat

A carpet surface and floor mat technology, which is applied in the field of replacing the carpet surface assembled floor mat, can solve the problems that the assembled floor mat part and edges are easy to lift, consume a lot of manpower and material resources, and the single-buckle structure is easy to fall off. Service, solve the installation effectiveness, the effect of not easy to warp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

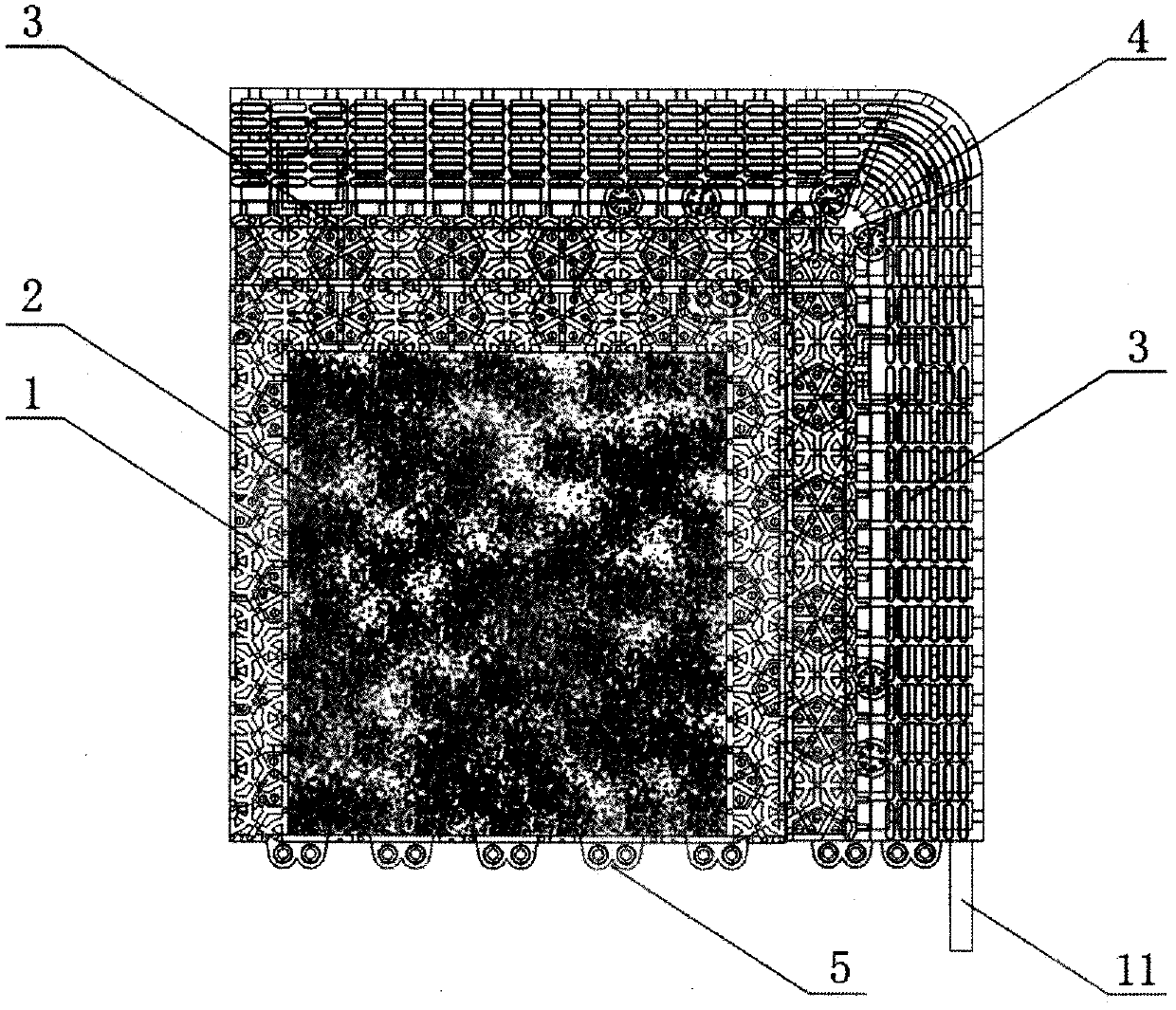

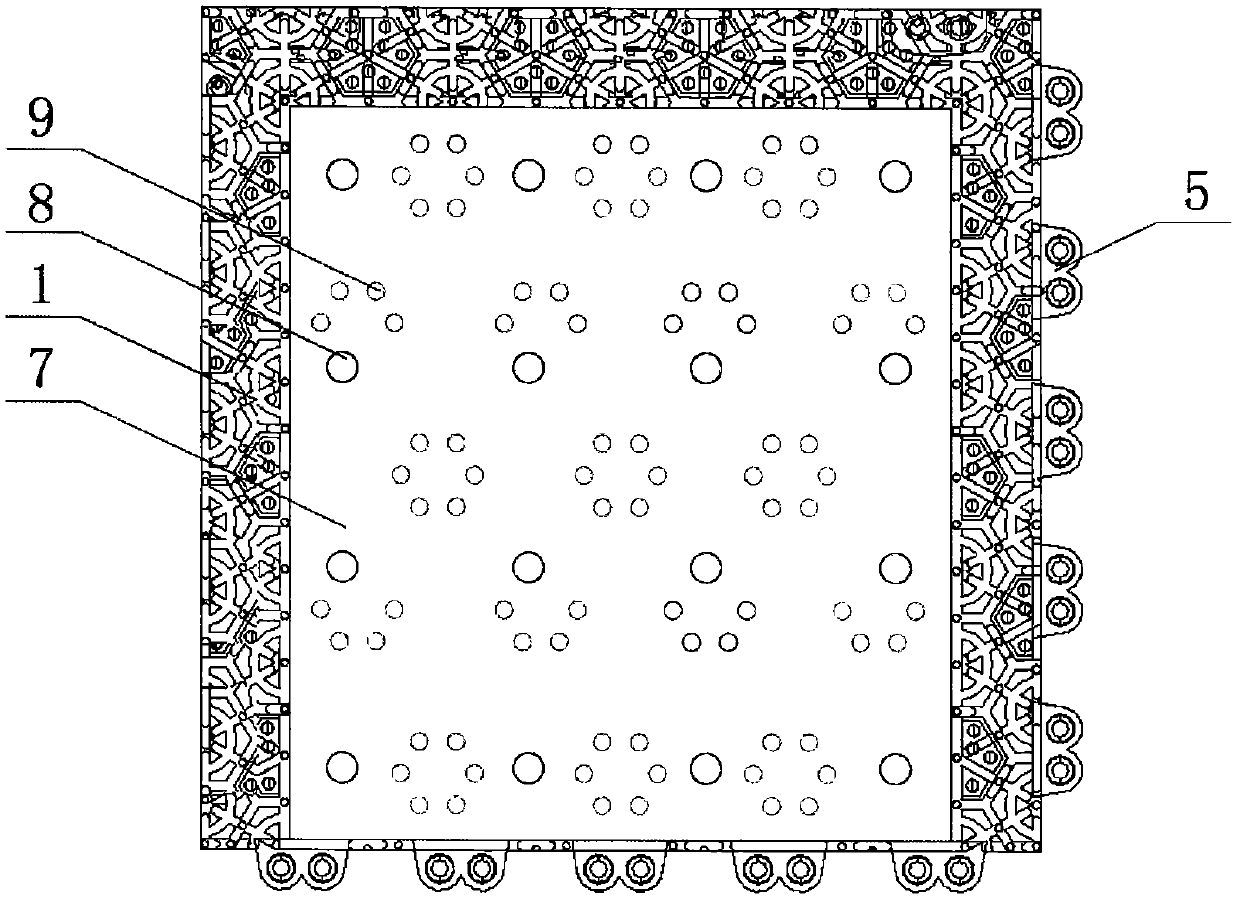

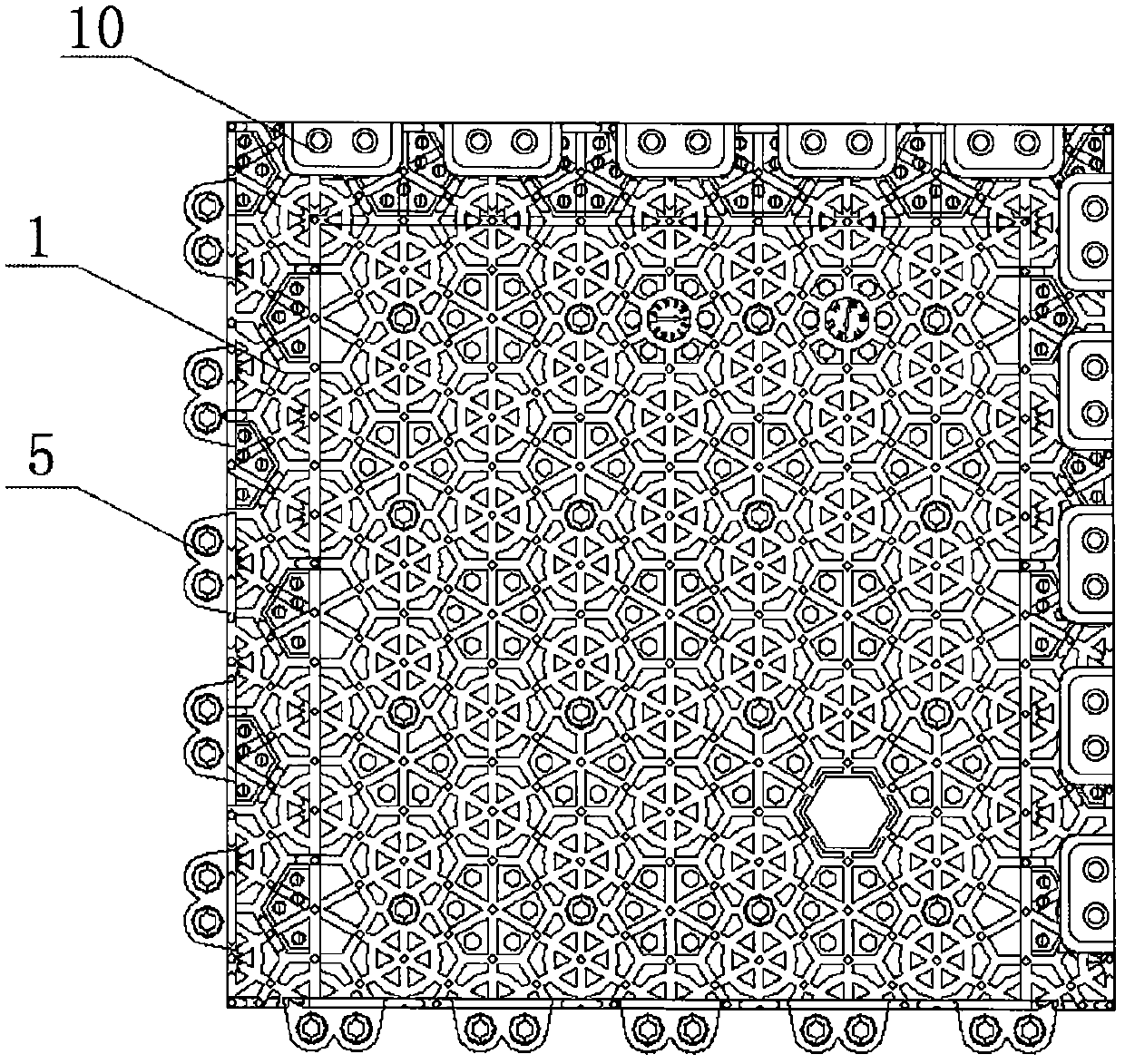

[0031] according to Figure 1 to Figure 9 Shown: a replacement carpet-type assembled floor mat, including a bottom frame body 1, a bevel body 3 and a bevel body 4 spliced with each other, and the bevel body 3 is provided with two adjacent to the bottom frame body 1 Splicing on both sides, the beveled body 4 is located between the ends of the two beveled bodies 3 that are close to each other and spliced with the two beveled bodies 3. This structure is the corner structure of the assembled floor mat. The length and width of the assembled floor mat A specified number of chassis body 1 and hypotenuse body 3 can be assembled as required, wherein:

[0032] Described base frame body 1 top surface is provided with groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com