Cleaning and drying integration device for mechanical parts

A technology for mechanical parts and cleaning devices, applied in the directions of dry gas arrangement, cleaning method using liquid, drying, etc., can solve the problems affecting the later use of products, poor cleaning effect, etc., to improve efficiency and ensure surface cleanliness , the effect of reducing the steps of the post-process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

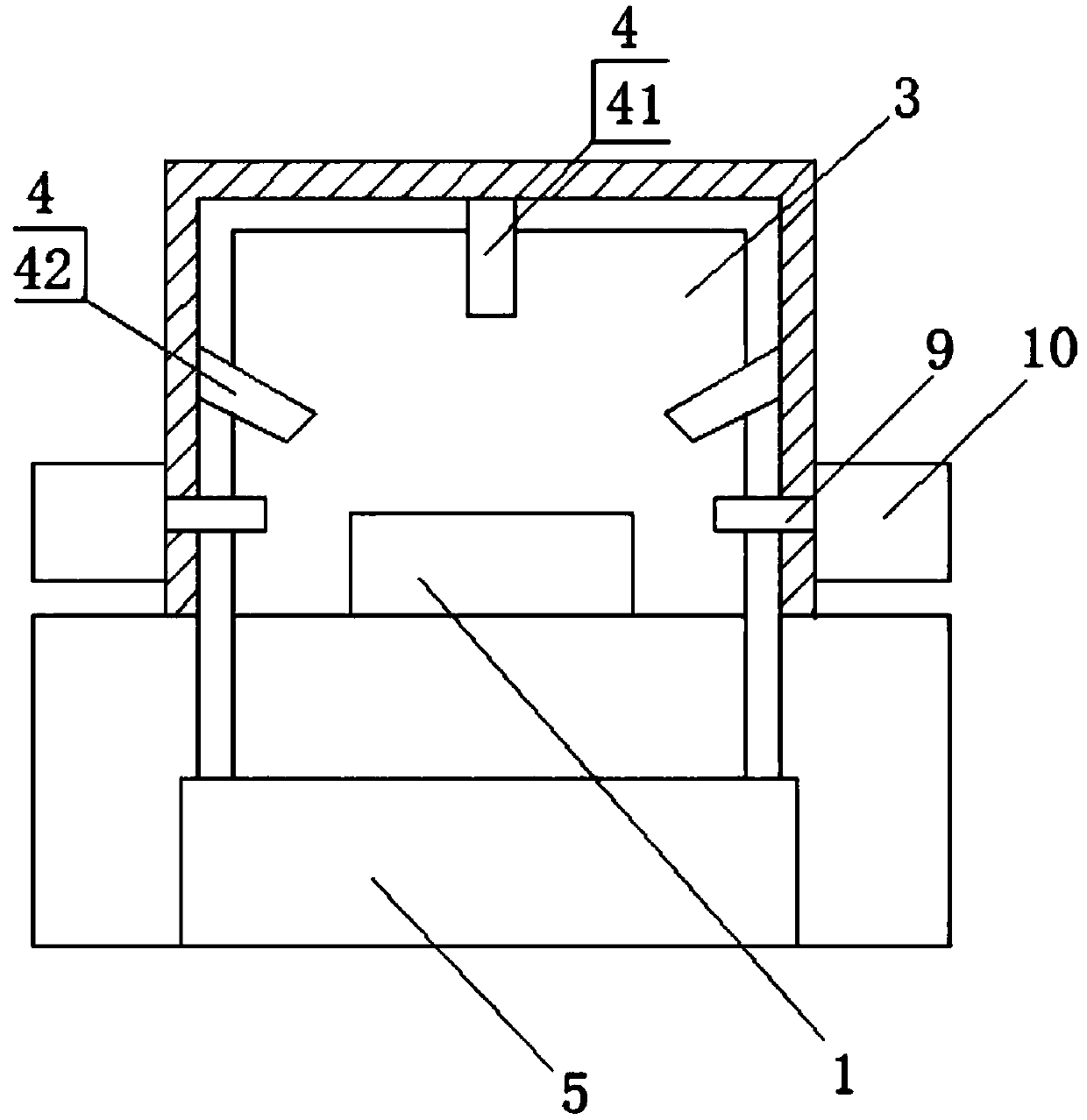

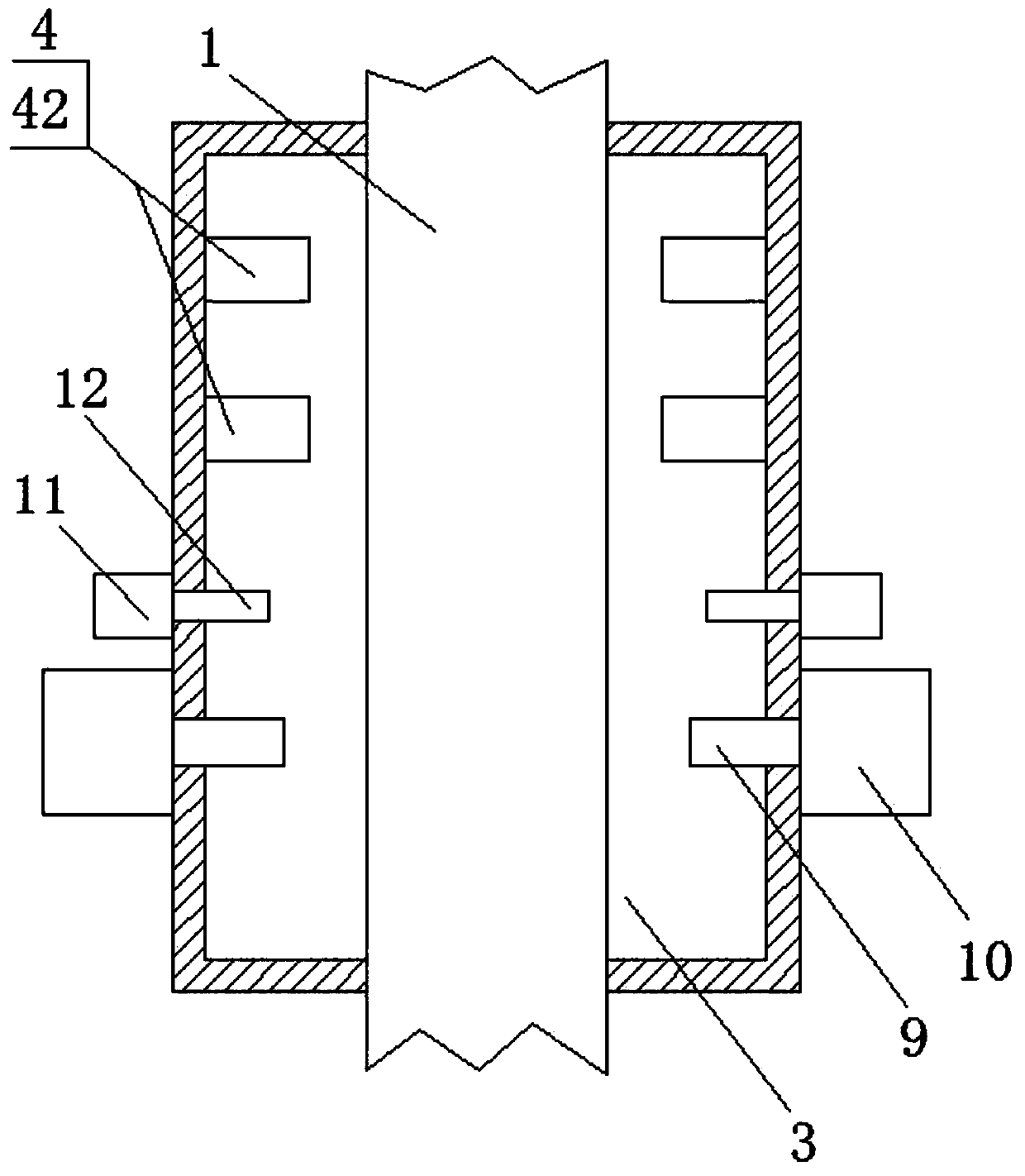

[0023] As an improvement of the present invention, the cleaning chamber 3 is provided with a plurality of ultrasonic cleaning devices, which are composed of an ultrasonic generator 11 and an ultrasonic transducer 12, wherein the ultrasonic transducer 12 extends to the inside of the cleaning chamber 3, The extension line of the axis of the ultrasonic transducer 12 intersects with the upper end surface of the transmission belt 1 . With the above design, the ultrasonic wave generated by the ultrasonic device can act on the mechanical parts, so that the dirt that may exist on the surface of the mechanical parts can be further cleaned, thereby improving the effect of the cleaning process.

[0024] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

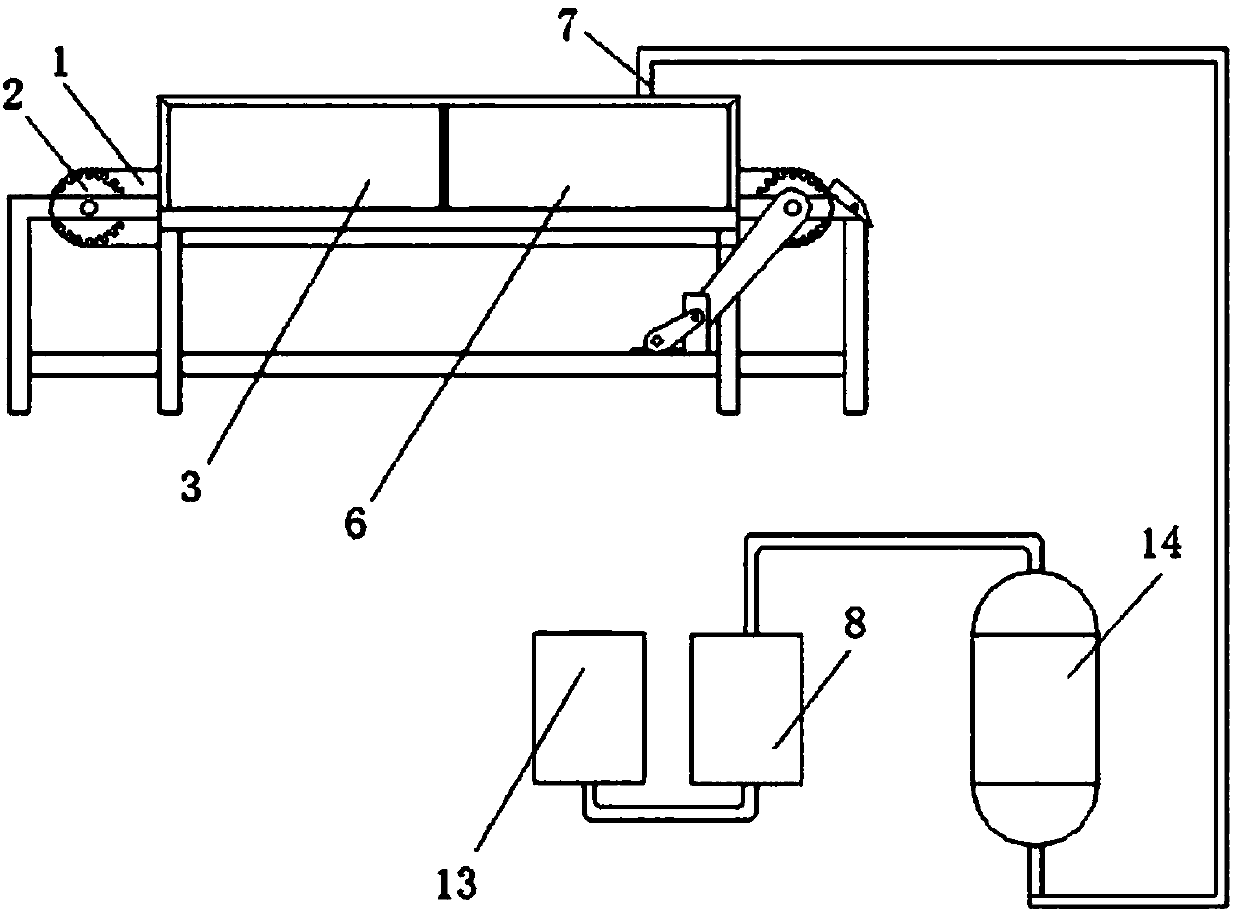

[0026] As an improvement of the present invention, the hot air blower 8 is communicated with an air desiccant 13 ; an air storage tank 14 is arranged between the hot air blower 8 and the drying nozzle 7 . With the above design, it can ensure the dryness of the drying gas to ensure the drying effect and avoid accidents caused by excessive air pressure in the pipeline.

[0027] The remaining features and advantages of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com