Double-head double-saw tractor

A tractor and clamping saw technology, applied in sawing machine devices, metal sawing equipment, tool dressing of sawing machine devices, etc., can solve the problems of poor control speed, large mechanical wear, inflexible activities, etc. Solve the effect of easy distortion and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

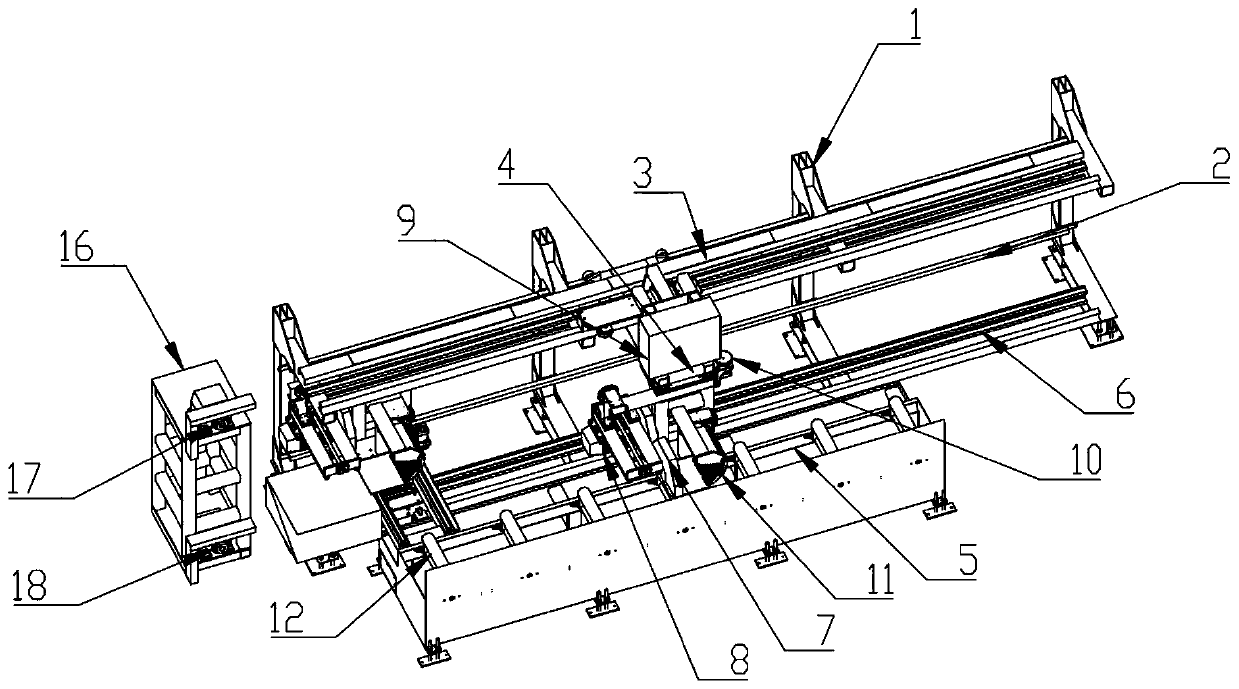

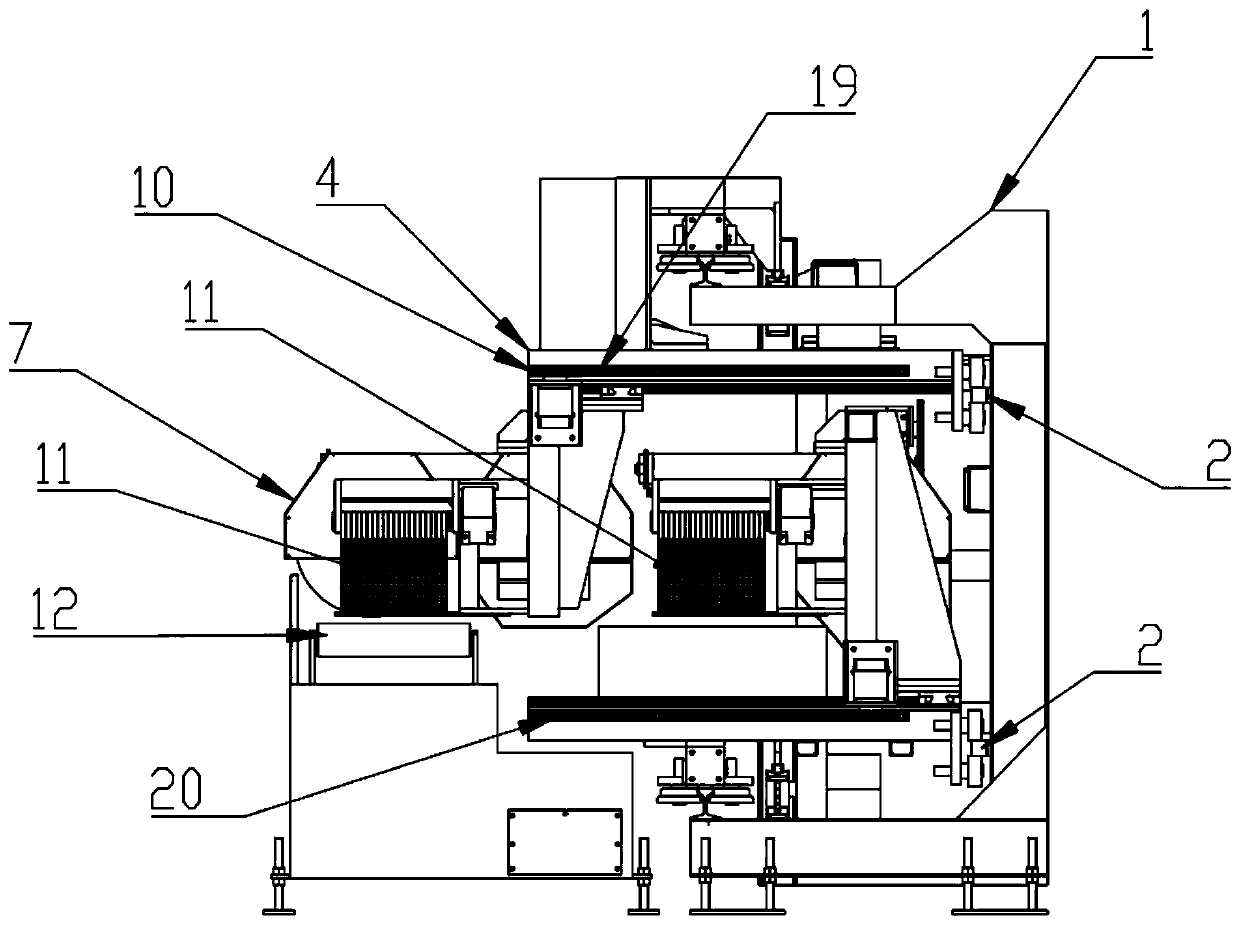

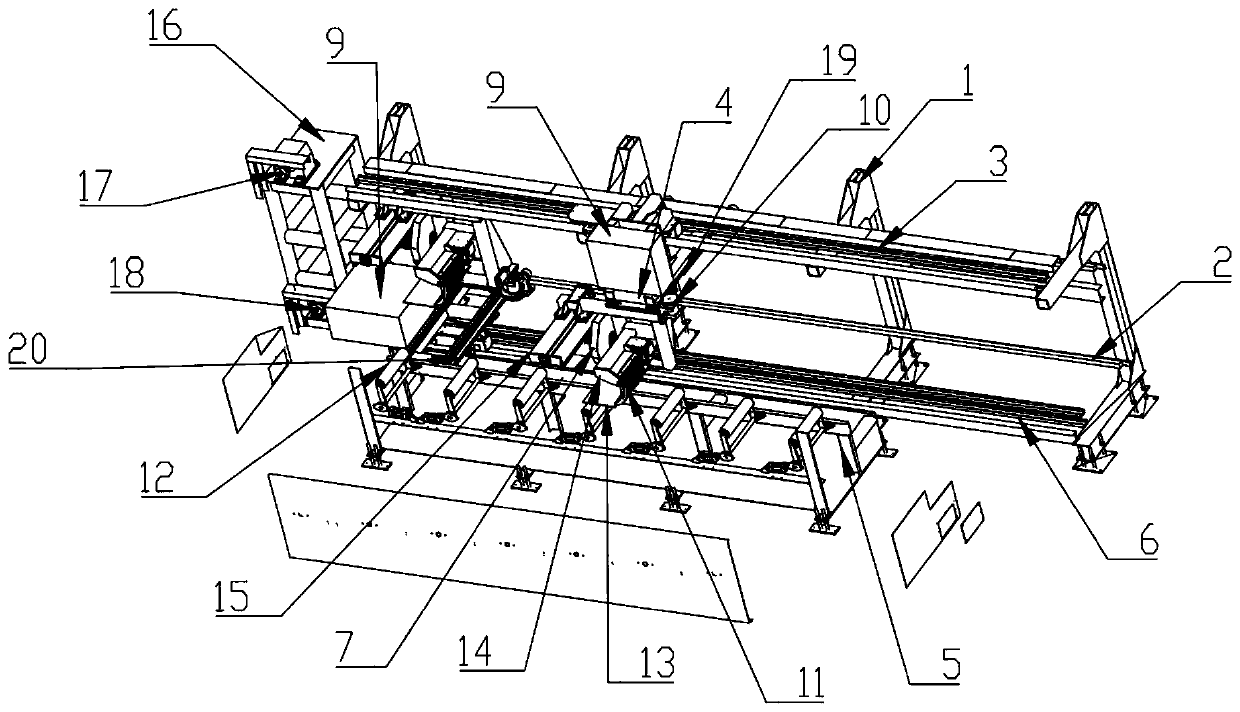

[0025] Embodiment one, such as Figure 1-6 As shown, this embodiment provides a double-headed double-saw tractor, including several support frames 1, two support rods 2, two guide rails, a first pull-saw device, a second pull-saw device, a transmission frame 5, The power motor 17 and the controller are characterized in that each of the support frames 1 is arranged on one side of the guide rail, each of the support frames 1 is equally spaced and distributed parallel to each other, and the support rods 2 are vertically fixedly connected to the The support frame 1, each of the guide rails is arranged on one side of the transmission frame 5 and is arranged in parallel with the transmission frame 5 along the length direction. The length direction of the guide rail extends, and the guide rail includes an upper guide rail 3 and a lower guide rail 6, and the first pulling saw device and the second pulling saw device are respectively installed on the upper guide rail 3 and the lower gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com