Workpiece safety intelligent polishing machine

A polishing machine and safety technology, applied in the field of polishing machines, can solve the problems of resource waste, polishing efficiency and low safety, and achieve the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

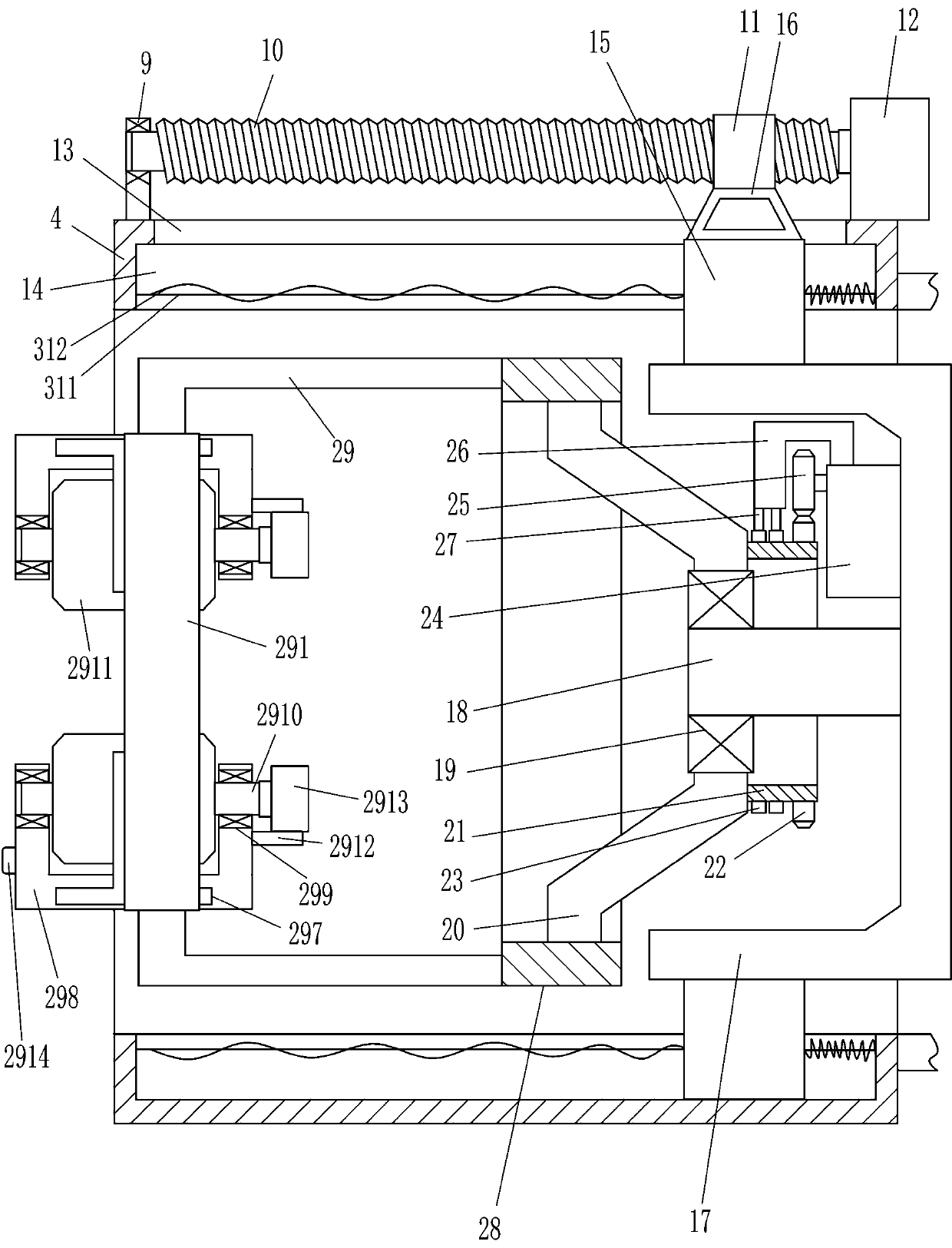

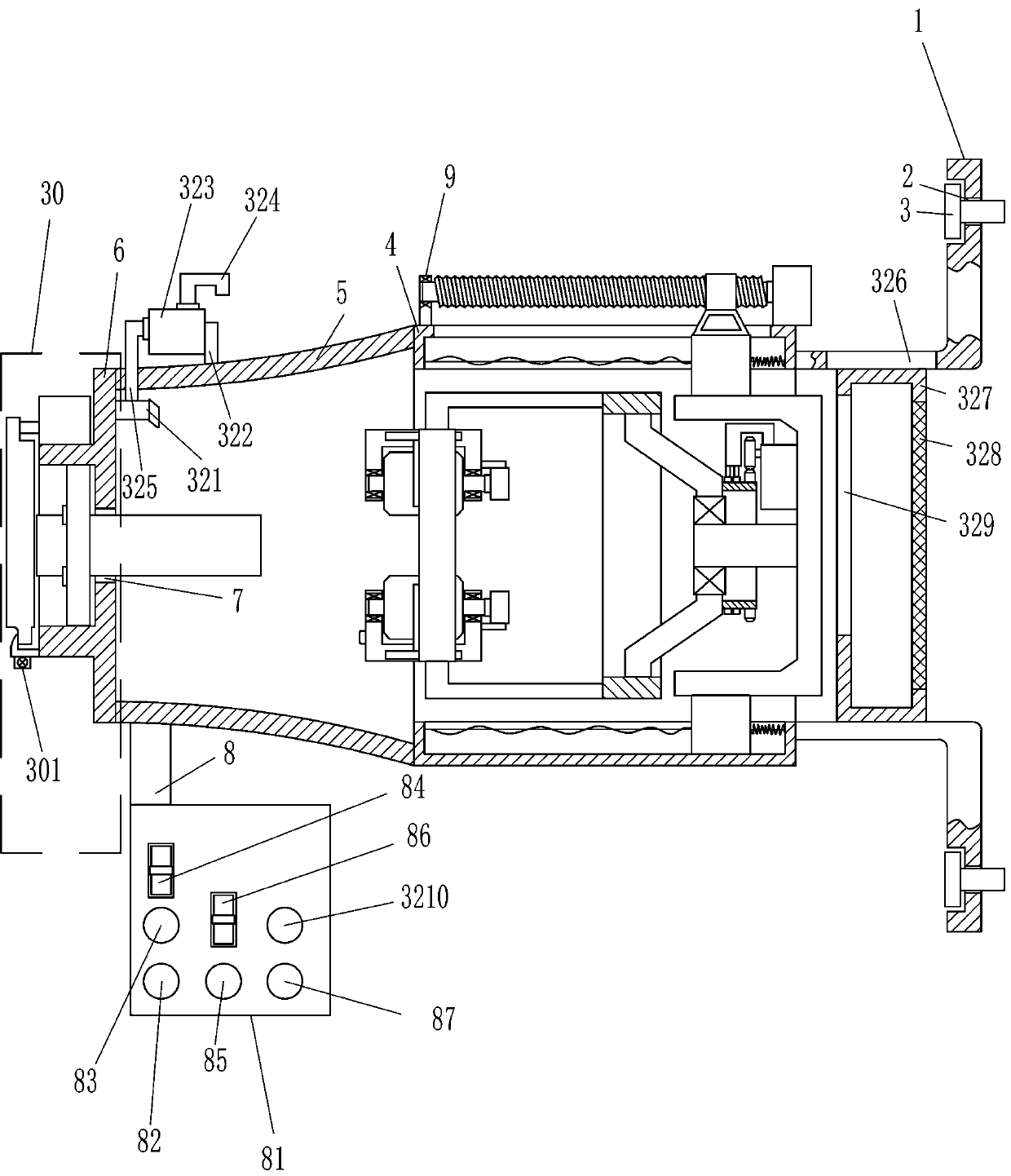

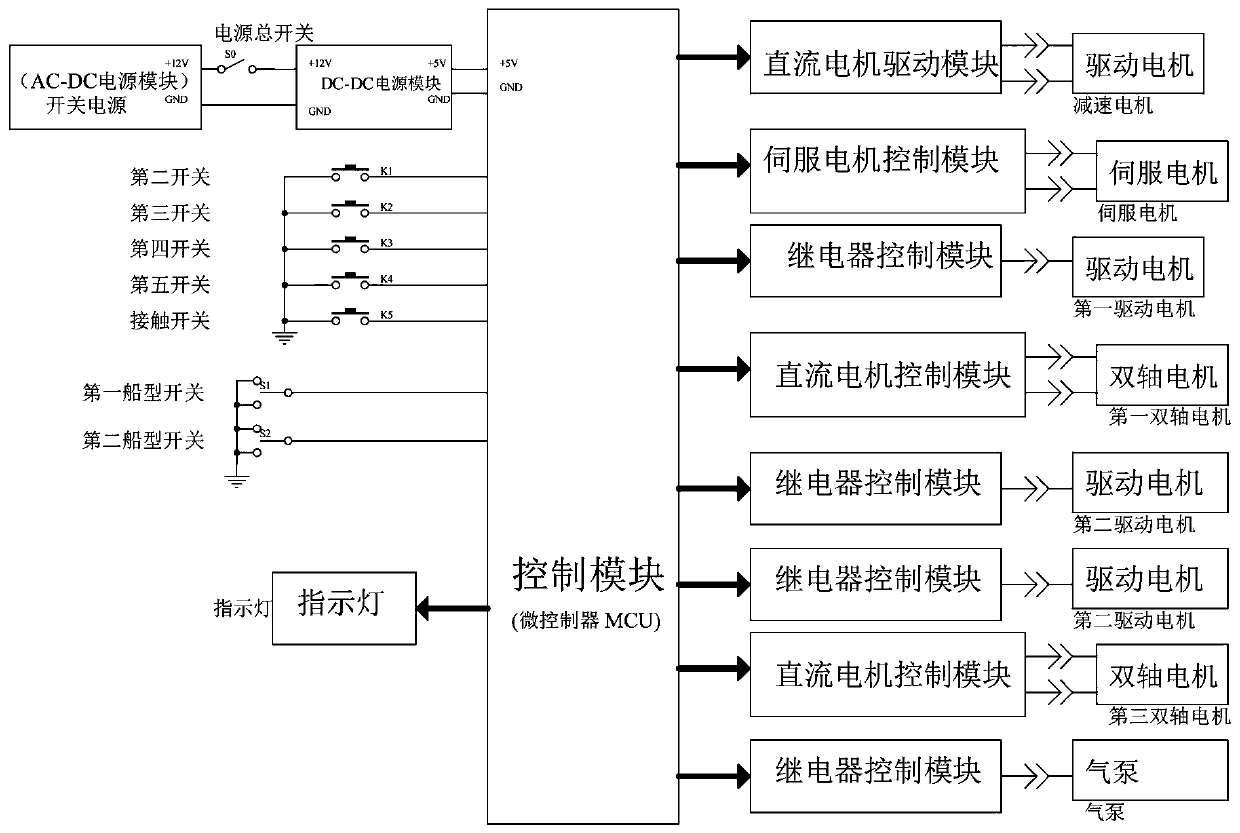

[0020] A workpiece safety intelligent polishing machine, such as Figure 1-7As shown, it includes installation frame 1, expansion screw 3, installation box 4, operation box 5, observation glass 51, fixed frame 6, first connection block 8, control box 81, main power switch 82, second switch 83, the first A ship type switch 84, the third switch 85, the second ship type switch 86, the fourth switch 87, the first bearing block 9, the first screw mandrel 10, the first nut 11, the reduction motor 12, the slide rail 14, the slide block 15, The second connecting block 16, the first N-shaped frame 17, the fixed rod 18, the second bearing seat 19, the first connecting frame 20, the first rotating ring 21, the first gear 22, the receiving ring 23, and the first driving motor 24 , second gear 25, second connecting frame 26, electrode 27, second rotating ring 28, third connecting frame 29, second N-shaped frame 291, first guide rail 292, first guide sleeve 293, third bearing seat 294 , th...

Embodiment 2

[0022] A workpiece safety intelligent polishing machine, such as Figure 1-7 As shown, it includes installation frame 1, expansion screw 3, installation box 4, operation box 5, observation glass 51, fixed frame 6, first connection block 8, control box 81, main power switch 82, second switch 83, the first A ship type switch 84, the third switch 85, the second ship type switch 86, the fourth switch 87, the first bearing block 9, the first screw mandrel 10, the first nut 11, the reduction motor 12, the slide rail 14, the slide block 15, The second connecting block 16, the first N-shaped frame 17, the fixed rod 18, the second bearing seat 19, the first connecting frame 20, the first rotating ring 21, the first gear 22, the receiving ring 23, and the first driving motor 24 , second gear 25, second connecting frame 26, electrode 27, second rotating ring 28, third connecting frame 29, second N-shaped frame 291, first guide rail 292, first guide sleeve 293, third bearing seat 294 , t...

Embodiment 3

[0025] A workpiece safety intelligent polishing machine, such as Figure 1-7As shown, it includes installation frame 1, expansion screw 3, installation box 4, operation box 5, observation glass 51, fixed frame 6, first connection block 8, control box 81, main power switch 82, second switch 83, the first A ship type switch 84, the third switch 85, the second ship type switch 86, the fourth switch 87, the first bearing block 9, the first screw mandrel 10, the first nut 11, the reduction motor 12, the slide rail 14, the slide block 15, The second connecting block 16, the first N-shaped frame 17, the fixed rod 18, the second bearing seat 19, the first connecting frame 20, the first rotating ring 21, the first gear 22, the receiving ring 23, and the first driving motor 24 , second gear 25, second connecting frame 26, electrode 27, second rotating ring 28, third connecting frame 29, second N-shaped frame 291, first guide rail 292, first guide sleeve 293, third bearing seat 294 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com