A manufacturing system fault tracing method and system based on a digital twin model

A manufacturing system and twinning technology, applied in complex mathematical operations, design optimization/simulation, computer-aided design, etc., to achieve the effect of improving diagnosability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

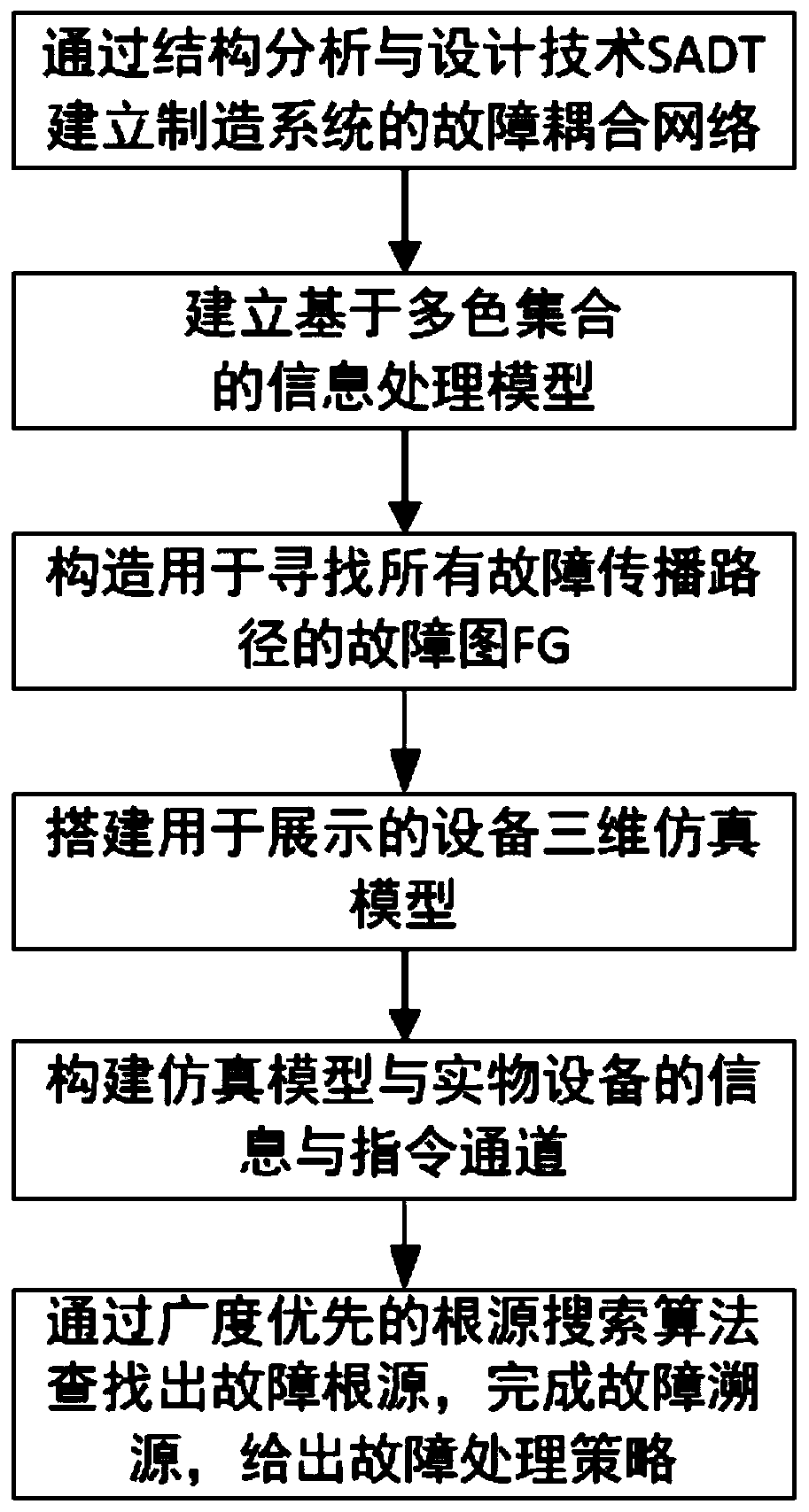

[0039] The manufacturing system fault tracing method based on the digital twin model of this embodiment, such as figure 1 shown, including the following steps:

[0040] Step A, build a mathematical model of the fault traceability of the digital twin on the simulation platform:

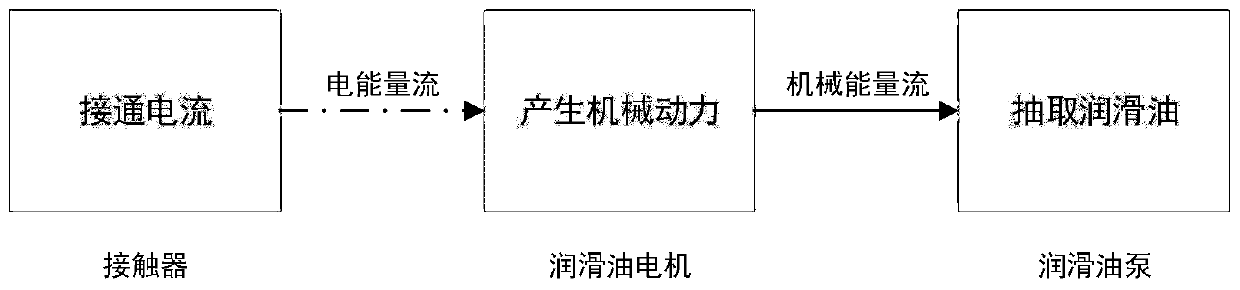

[0041] Step A1, obtain the functional coupling relationship, nodes and directed edges among the components in the manufacturing system through the structural analysis and design technology SADT, and establish the fault coupling network of the manufacturing system;

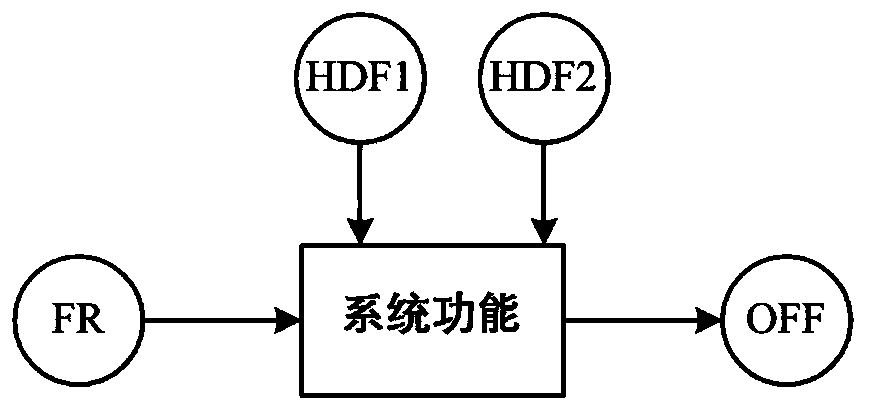

[0042] Step A2, obtain the coupling connection relationship between the multi-attributes of the fault mode in the fault coupling network of the manufacturing system through the multi-color set, and establish an information processing model based on the multi-color...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com