Permanent magnet synchronous spiral linear motor

A linear motor, permanent magnet synchronous technology, applied in the field of electric motors, can solve the problems of increasing the complexity of the motion mechanism, increase the complexity of control, etc., and achieve the effects of high linear motion accuracy, small starting current, and simple motion mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

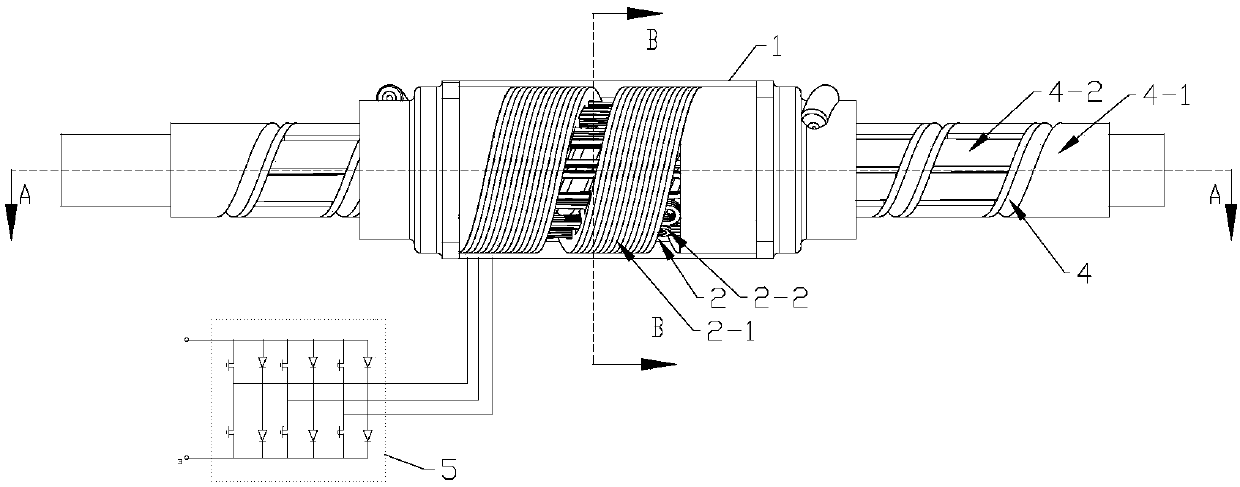

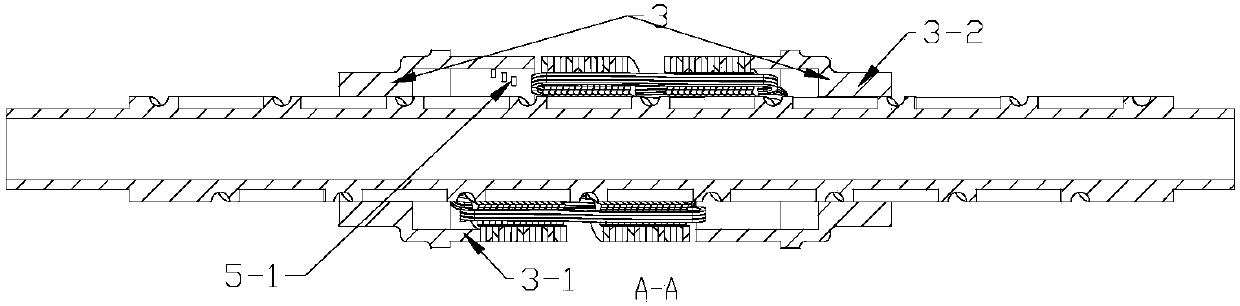

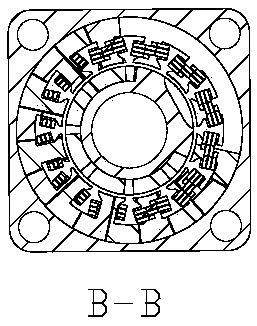

[0018] Such as figure 1 , 2 , shown in 3: a permanent magnet synchronous helical linear motor, comprising: a shell 1, an armature 2 set with the shell 1, an end cover 3 with a ball nut 3-2 connected to the two ends of the shell 1, and the armature 2 and The rotatable exciter 4 set by the end cover 3, the control circuit 5 connected to the coil group 2-2 of the armature 2 to supply power to the armature 2; the armature 2 is composed of a spiral iron core 2-1 and a coil group 2-2; the exciter 4 is composed of a cylindrical yoke 4-1 and a number of permanent magnet tiles 4-2 uniformly distributed on the circumferential surface of the yoke 4-1 in a spiral shape; it is characterized in that: The spiral core 2-1 of the armature 2 is to form a number of magnetic poles by punching evenly distributed notches in the inner circle of several annular silicon steel sheets, break a gap at the same position of several annular silicon steel sheets, and place several annular silicon steel shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com