Hydraulic lifting column with shallow embedding depth

A hydraulic lifting column and pre-embedded technology, applied in the field of lifting columns, can solve problems such as poor anti-collision effect, easy damage maintenance, and difficult construction, and achieve the effects of convenient installation and maintenance, good crashworthiness, and reduced water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

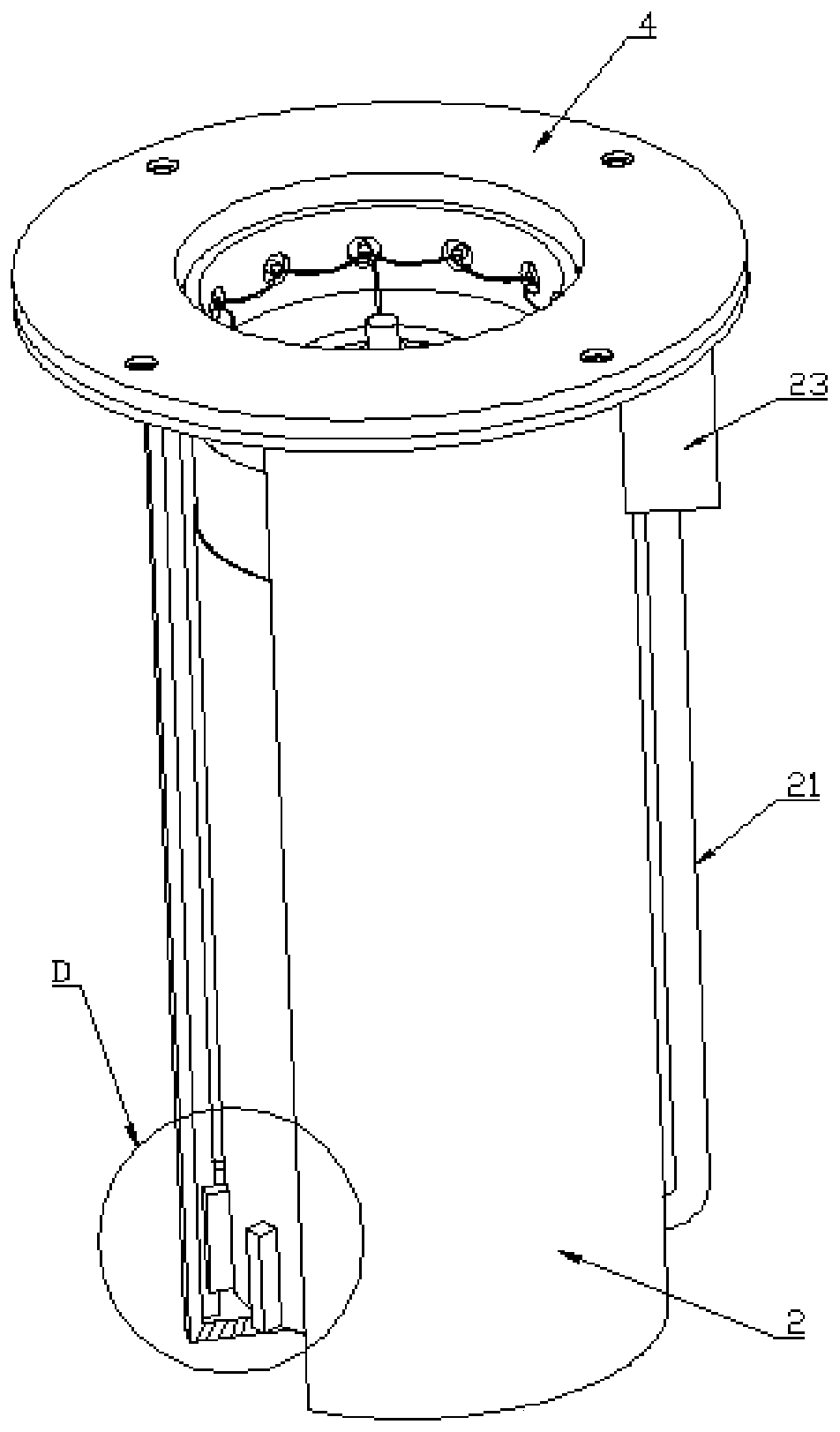

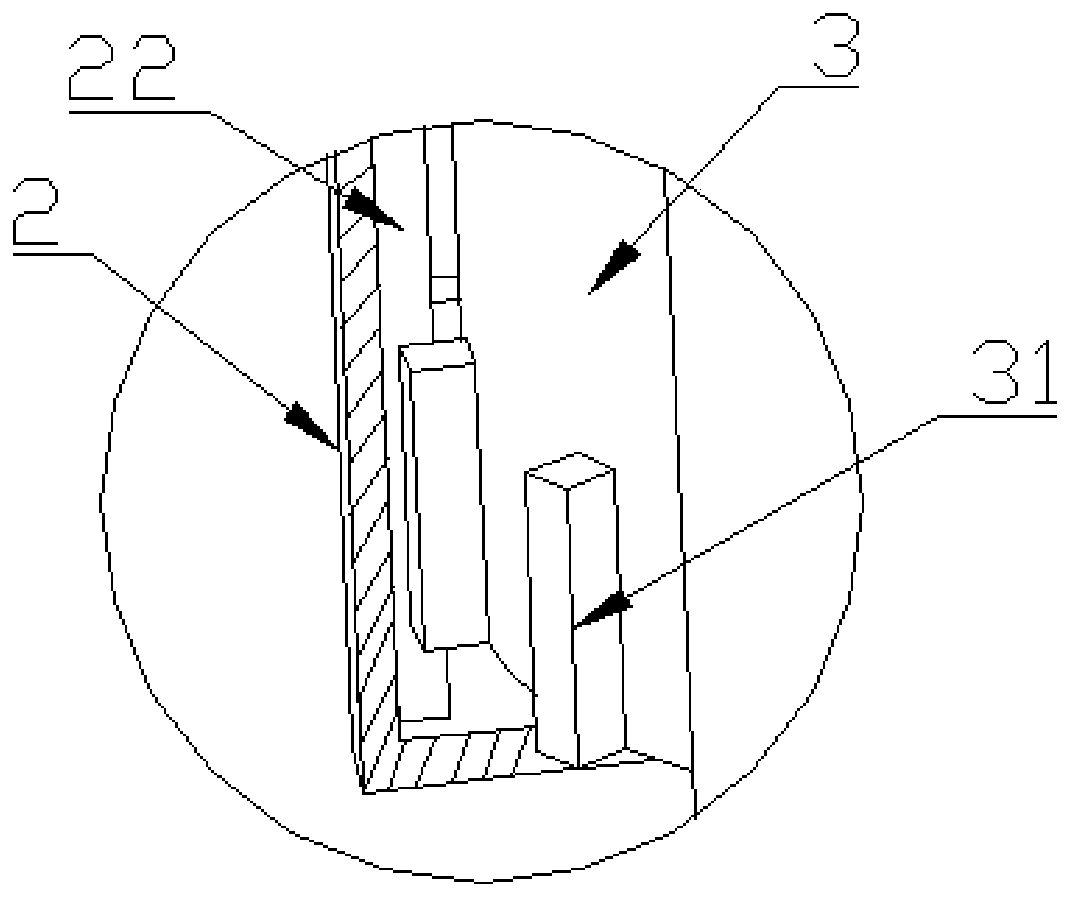

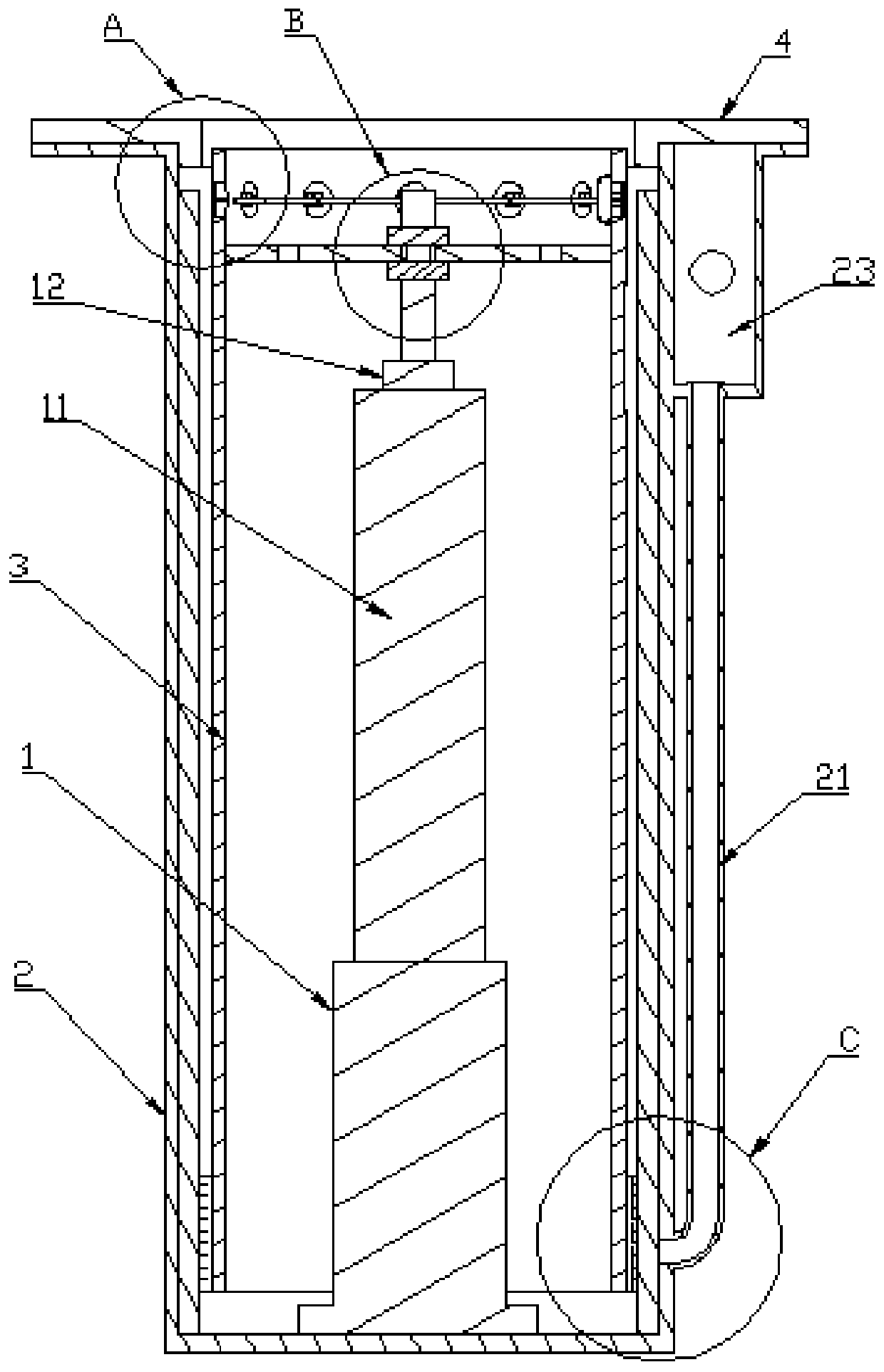

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0031] Such as figure 1 As shown, a hydraulic lifting column with a shallow pre-embedded depth provided in this embodiment includes a pre-embedded barrel 2 and a lifting inner column 3. The pre-embedded barrel 2 is all buried under the ground, and the lifting inner column 3 is located Among them, it also includes double-section hydraulic motor 1. Using double-section hydraulic motor 1 is simpler than directly using liquid to drive construction. You only need to install a fixed motor and connect the control wires to the main control box outside to realize the lifting of the whole group. The column is running, and the liquid-driven lifting column needs to set up a special infusion pipeline, and it is very troublesome to repair when the pipeline leaks. One end of the double-section hydraulic motor 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com