Voltage trimming method

A voltage and measurement technology, applied in the direction of measuring electricity, measuring electrical variables, and electronic circuit testing, etc., can solve the problems of long file-seeking time in the voltage trimming method, and achieve the problem of overcoming the range that does not meet the demand and avoiding the long-term file-seeking time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

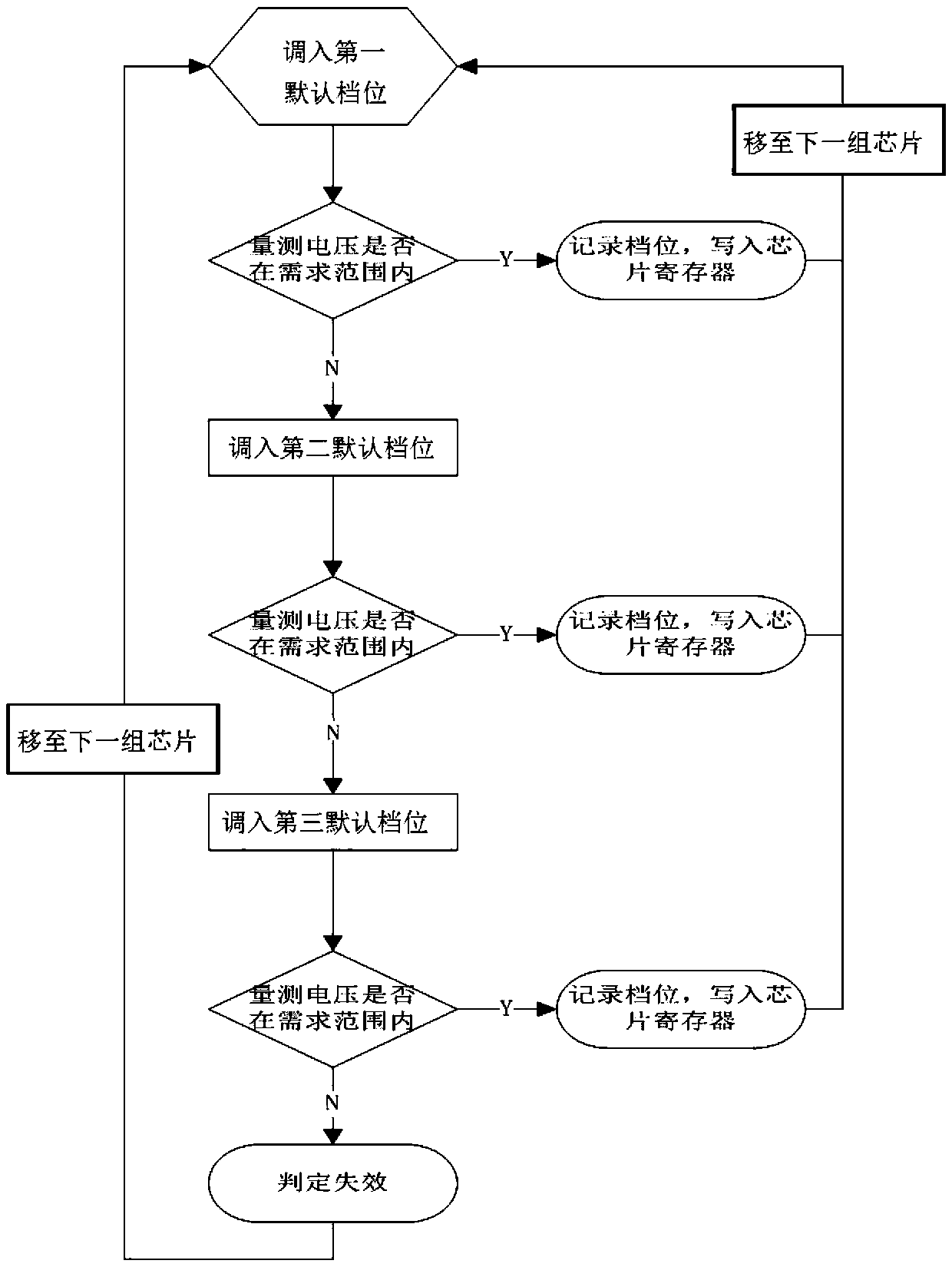

[0030] The voltage adjustment method proposed by the present invention will be further described in detail below in conjunction with the drawings and specific embodiments. According to the following description and claims, the advantages and features of the present invention will be clearer. It should be noted that the drawings are in a very simplified form and all use imprecise proportions, which are only used to conveniently and clearly assist in explaining the purpose of the embodiments of the present invention.

[0031] The core idea of the present invention is to provide a voltage trimming method to solve the problem of long search time for the existing voltage trimming method.

[0032] In order to realize the above-mentioned idea, the present invention provides a voltage adjustment method, the voltage adjustment method includes: establishing a program sub-function in the test machine; placing the wafer on the probe station and adjusting the first default gear Into the test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com