Method for evaluating temperatures in active heave compensation ropes

A roped, active technology that can be used in thermometers that give differential values, earthwork drilling, special data processing applications, etc., to solve problems such as not focusing on specific windows of interest

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

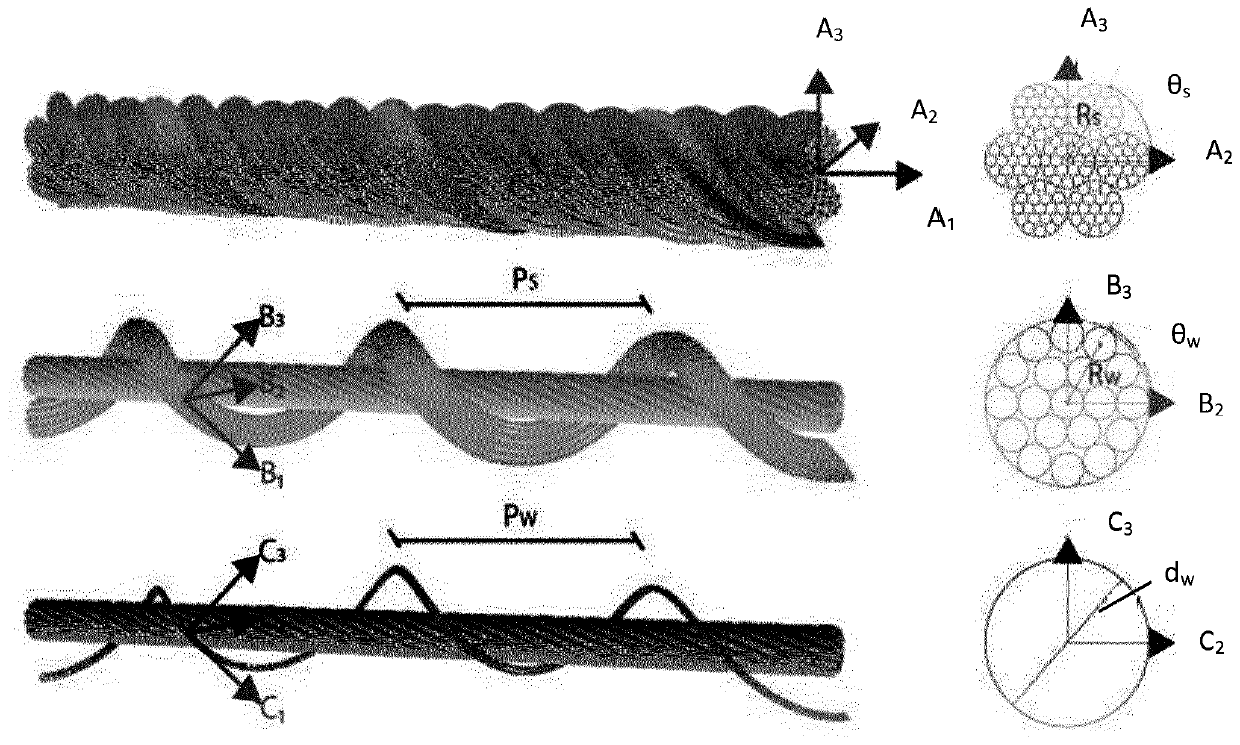

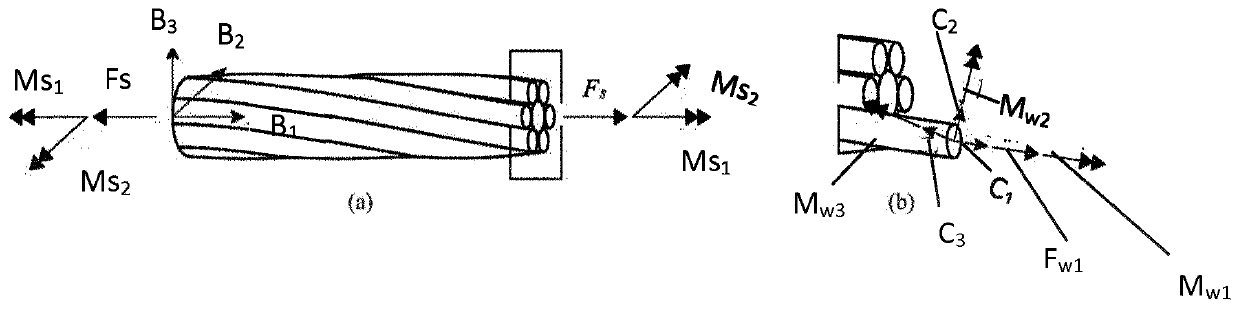

[0016] A method for evaluating the temperature in an active heave compensation rope has been defined in relation to a mechanical model and a thermal model. Calibration of the model has been carried out through extensive experimental campaigns. Set-up tests have been performed combining the various inputs (load, speed, D / d) with the rope to determine the internal and external temperature change (ΔT) of the wire rope relative to the ambient temperature.

[0017] Referring now to the drawings and in particular to figure 1 , the method S100 for evaluating the temperature in an active heave compensation rope includes the following steps in chronological order:

[0018] - S110 describes the geometry of the wire rope as a composite structure obtained by assembling helical components in layers, the layers being the wire, the rope and the rope itself;

[0019] - S120 uses a mechanical model of the rope showing the material properties of each wire under the assumption of linear elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com