Method and latex product for natural rubber latex prevulcanization

A natural latex and pre-vulcanization technology, applied in the field of natural rubber processing, can solve the problems of inability to popularize and apply, low cross-linking density, poor mechanical properties of products, etc., and achieve the effect of being beneficial to production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

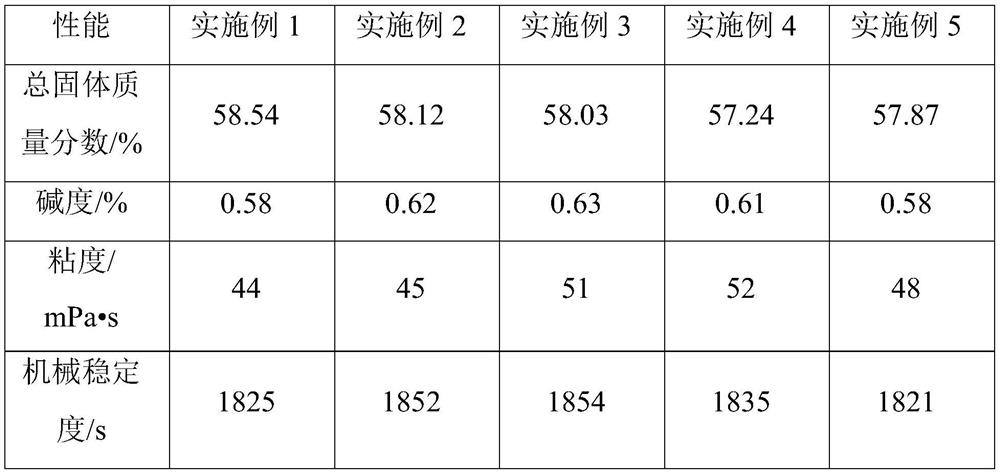

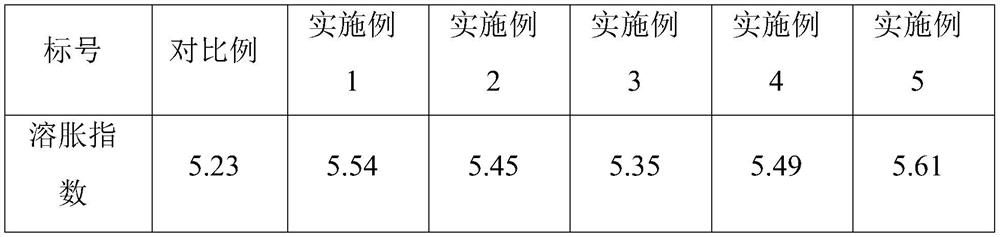

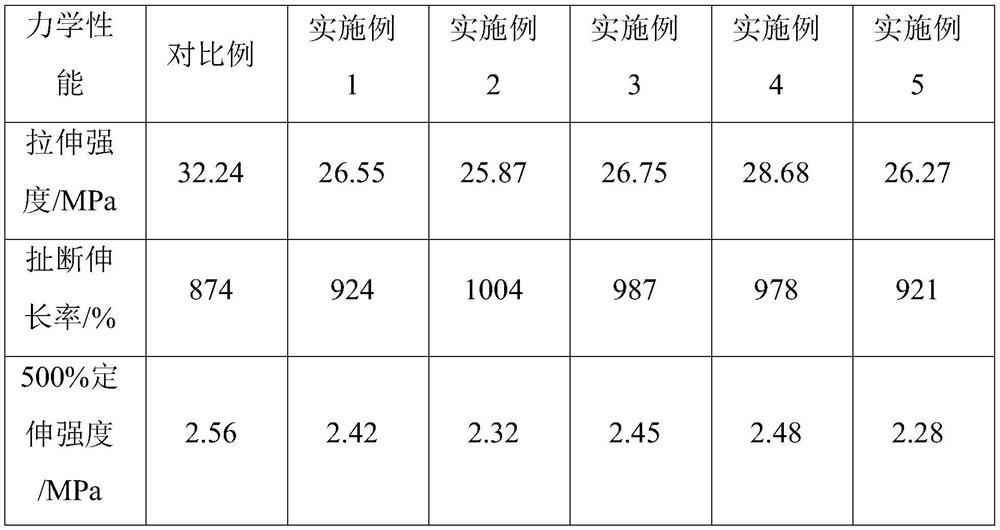

Embodiment 1

[0040] Weigh 16666 parts of concentrated natural rubber latex with a total solid mass fraction of 60%, and add it into a vulcanization reactor with a heating jacket. Under stirring conditions, add 100 parts of 20% potassium hydroxide aqueous solution, 100 parts of 20% Pingpinga "O" aqueous solution and 1500 parts of 20% diallyl monosulfide emulsification aqueous solution. After about ten minutes, under stirring conditions, 80 parts by mass fraction of 20% cumene hydrogen peroxide emulsified aqueous solution and 20 parts by mass fraction of 50% tetraethylenepentamine aqueous solution were added. Vulcanized at room temperature for 24 hours under the protection of nitrogen to obtain pre-vulcanized natural rubber latex.

Embodiment 2

[0042] Weigh 16666 parts of concentrated natural rubber latex with a total solid mass fraction of 60%, and add it into a vulcanization reactor with a heating jacket. Under stirring conditions, add 100 parts of 20% potassium hydroxide aqueous solution, 100 parts of 20% Pingpinga "O" aqueous solution and 1400 parts of 20% diallyl disulfide emulsification aqueous solution. After about ten minutes, under stirring conditions, 80 parts by mass fraction of 20% cumene hydrogen peroxide emulsified aqueous solution and 25 parts by mass fraction of 50% tetraethylenepentamine aqueous solution were added. Vulcanized at room temperature for 24 hours under the protection of nitrogen to obtain pre-vulcanized natural rubber latex.

Embodiment 3

[0044] Weigh 16666 parts of concentrated natural rubber latex with a total solid mass fraction of 60%, and add it into a vulcanization reactor with a heating jacket. Under stirring conditions, add 100 parts of 20% potassium hydroxide aqueous solution, 100 parts of 20% Pingpinga "O" aqueous solution and 600 parts of 20% diallyl disulfide emulsification Aqueous solution, 1000 parts by mass fraction is 20% diallyl trisulfide emulsified aqueous solution. After about ten minutes, under stirring condition, 90 parts by mass fraction of 20% cumene hydrogen peroxide emulsified aqueous solution and 30 parts by mass fraction of 50% tetraethylenepentamine aqueous solution were added. Vulcanized at room temperature for 24 hours under the protection of nitrogen to obtain pre-vulcanized natural rubber latex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com