Radiation refrigeration coating material and preparation method thereof

A coating material and radiant cooling technology, applied in coatings, polyurea/polyurethane coatings, sustainable manufacturing/processing, etc., can solve problems such as limited application, complicated process, and large equipment investment, and achieve moisture suppression and adhesion strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

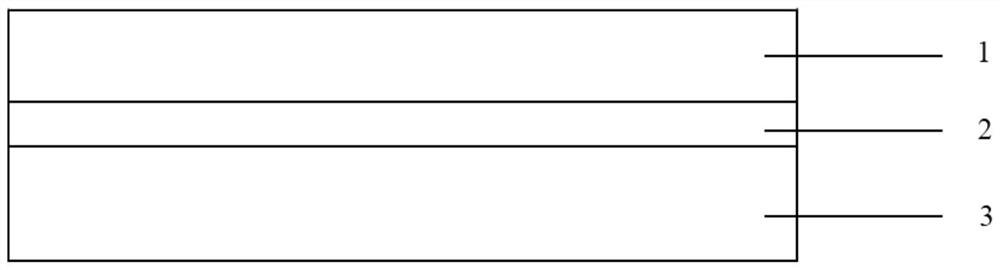

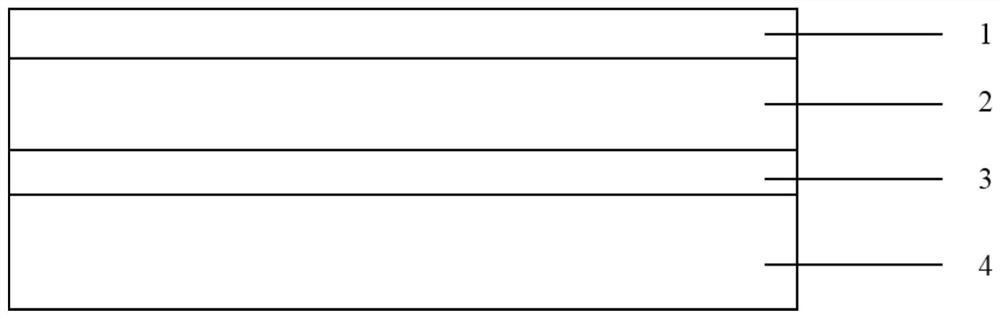

Image

Examples

Embodiment 1

[0058] (1) The base material is made of 6 series aluminum alloy with a thickness of 2mm (purchased from Shenzhen Hongnian Metal Materials Co., Ltd.), with an area of 75×150mm, and the surface is polished with 240# water sandpaper, 1000# water sandpaper and 1500# sandpaper in turn. Then use acetone and deionized water to ultrasonically clean the polished aluminum alloy surface, and dry the surface to obtain a treated aluminum alloy substrate.

[0059] (2) 0.5g of carbon nanotubes and 0.5g of graphene were added to 1L of 1-ethyl-2-pyrrolidone, and the carbon nanotubes with a solid concentration of 1mg / mL were prepared by ultrasonically stirring the solution and blending Graphene composite carbon material suspension.

[0060] (3) Place the base material on a heating platform, the heating temperature is 100°C, and the polyurethane is dissolved in dimethylacetamide (DMAC) to form a polyurethane slurry, and the volume ratio of the polyurethane to the dimethylacetamide is 4:1, The...

Embodiment 2

[0067] (1) The substrate is made of carbon fiber board (T300-Toray) with a thickness of 3mm, with an area of 50×50mm. The surface is textured and cleaned. The pretreatment is to use 240# water sandpaper, 1000# water sandpaper and 1500# sandpaper. The surface was polished, and then the polished carbon fiber surface was ultrasonically cleaned with acetone and deionized water, and the surface was blown dry to obtain a treated carbon fiber substrate.

[0068] (2) 0.6g carbon nanotubes, 0.3g graphene and 0.1g fullerene C 60 It was added to 1 L of tetrahydrofuran, and the composite suspension of carbon nanotubes / graphene as the main phase with a solid content concentration of 1 mg / mL was prepared by ultrasonic stirring and blending of the solution.

[0069] (3) Place the substrate on a heating platform, the heating temperature is 100°C, and the polyimide is dissolved in the polyimide slurry dissolved in dimethylformamide (DMF). The volume ratio of amide is 4:1, and the viscosity ...

Embodiment 3

[0076] (1) The base material is made of 6 series aluminum alloy with a thickness of 2mm (purchased from Shenzhen Hongnian Metal Materials Co., Ltd.), with an area of 75×150mm, and the surface is polished with 240# water sandpaper, 1000# water sandpaper and 1500# sandpaper in turn. Then use acetone and deionized water to ultrasonically clean the polished aluminum alloy surface, and dry the surface to obtain a treated aluminum alloy substrate.

[0077] (2) 0.5g of carbon nanotubes and 0.5g of graphene were added to 1L of 1-ethyl-2-pyrrolidone, and the carbon nanotubes with a solid concentration of 1mg / mL were prepared by ultrasonically stirring the solution and blending Graphene composite carbon material suspension.

[0078] (3) Place the base material on a heating platform, the heating temperature is 100°C, and the polyurethane is dissolved in dimethylacetamide (DMAC) to form a polyurethane slurry, and the volume ratio of the polyurethane to the dimethylacetamide is 4:1, The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com