Sound-insulation retaining wall for construction site

A construction site and retaining wall technology, applied in the direction of sound insulation, construction, building components, etc., can solve the problem of no sound insulation effect of the fixed board wall, and can not solve the problem of noise pollution, so as to control the problem of noise pollution, enhance the sound insulation effect, facilitate construction and The effect of disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

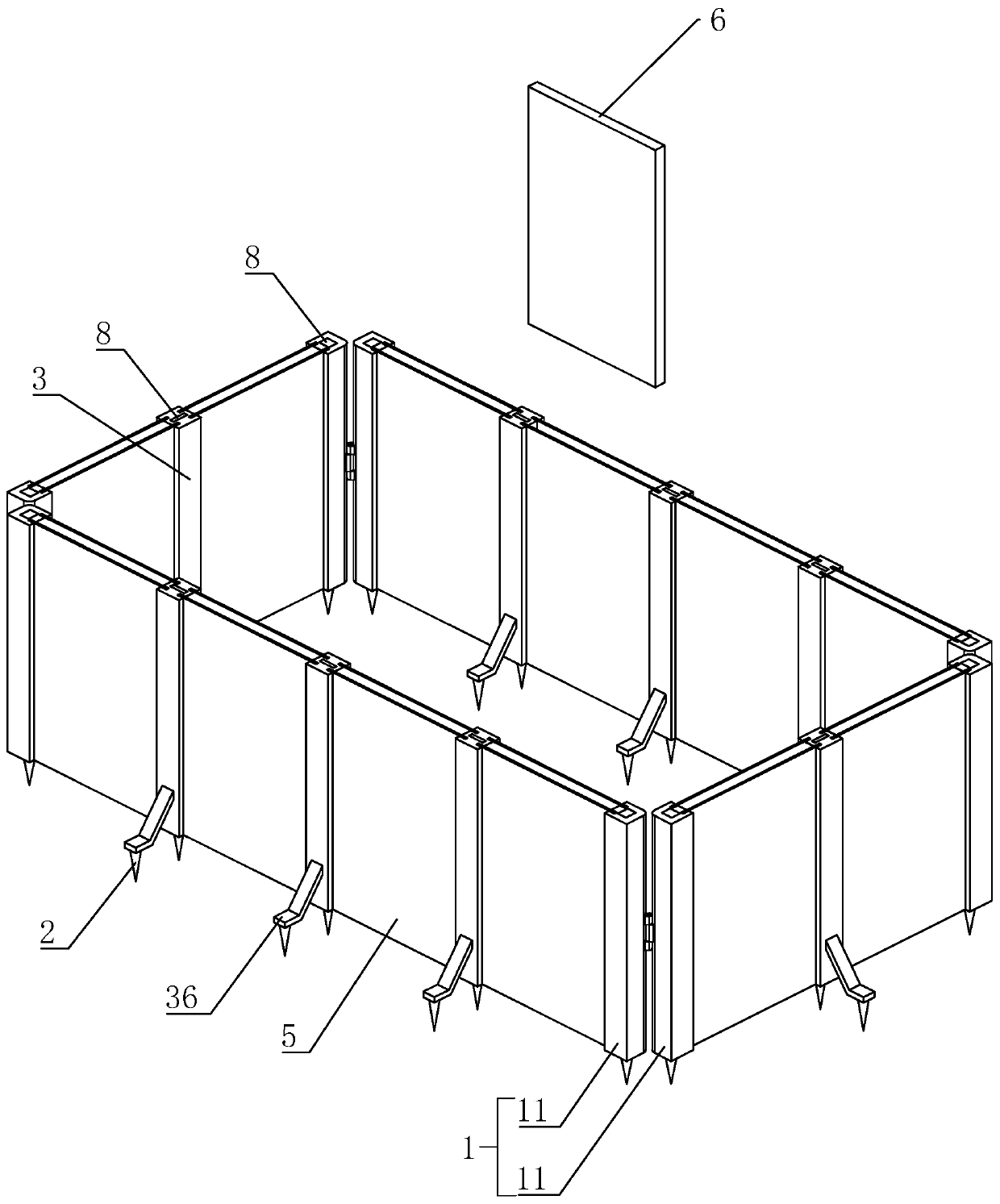

[0031] A construction site sound insulation retaining wall, such as figure 1 As shown, it includes corner pillars 1, side pillars 3 and partitions 5. The corner pillars 1 are located at the top corners of the soundproof retaining wall, and the side pillars 3 are evenly distributed on the connecting line between two adjacent corner pillars 1 . Partition boards 5 are arranged in pairs between two adjacent side pillars 3 and side pillars 3, and between side pillars 3 and corner pillars 1, forming a complete retaining wall and enclosing the noise source.

[0032] Such as figure 1 As shown, the corner pillar 1 and the side pillar 3 are arranged along the vertical direction, and pins 2 are fixedly connected to the bottom ends of the two. The corner pillar 1 and the side pillar 3 can be erected quickly by inserting the pin 2 into the soil layer of the foundation pit.

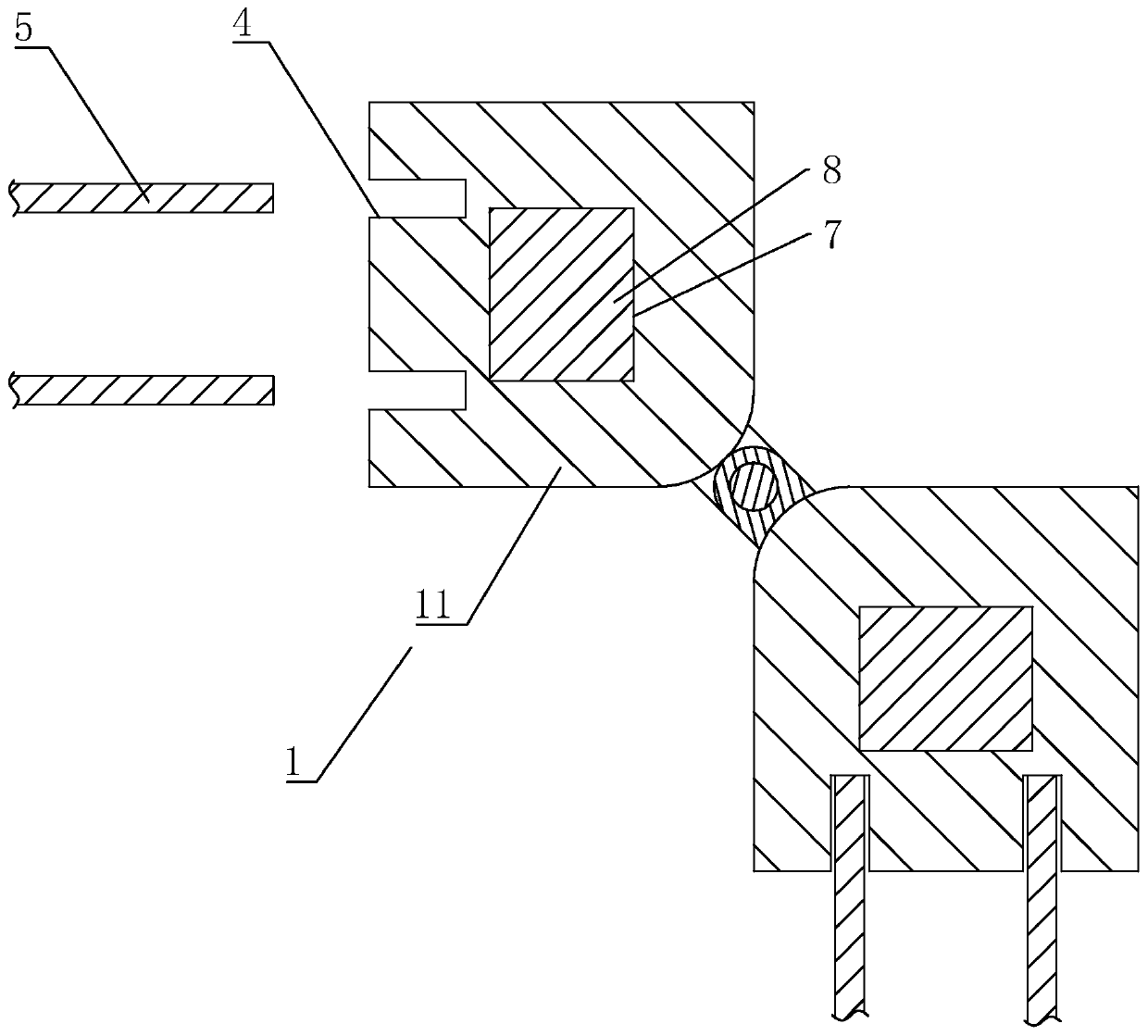

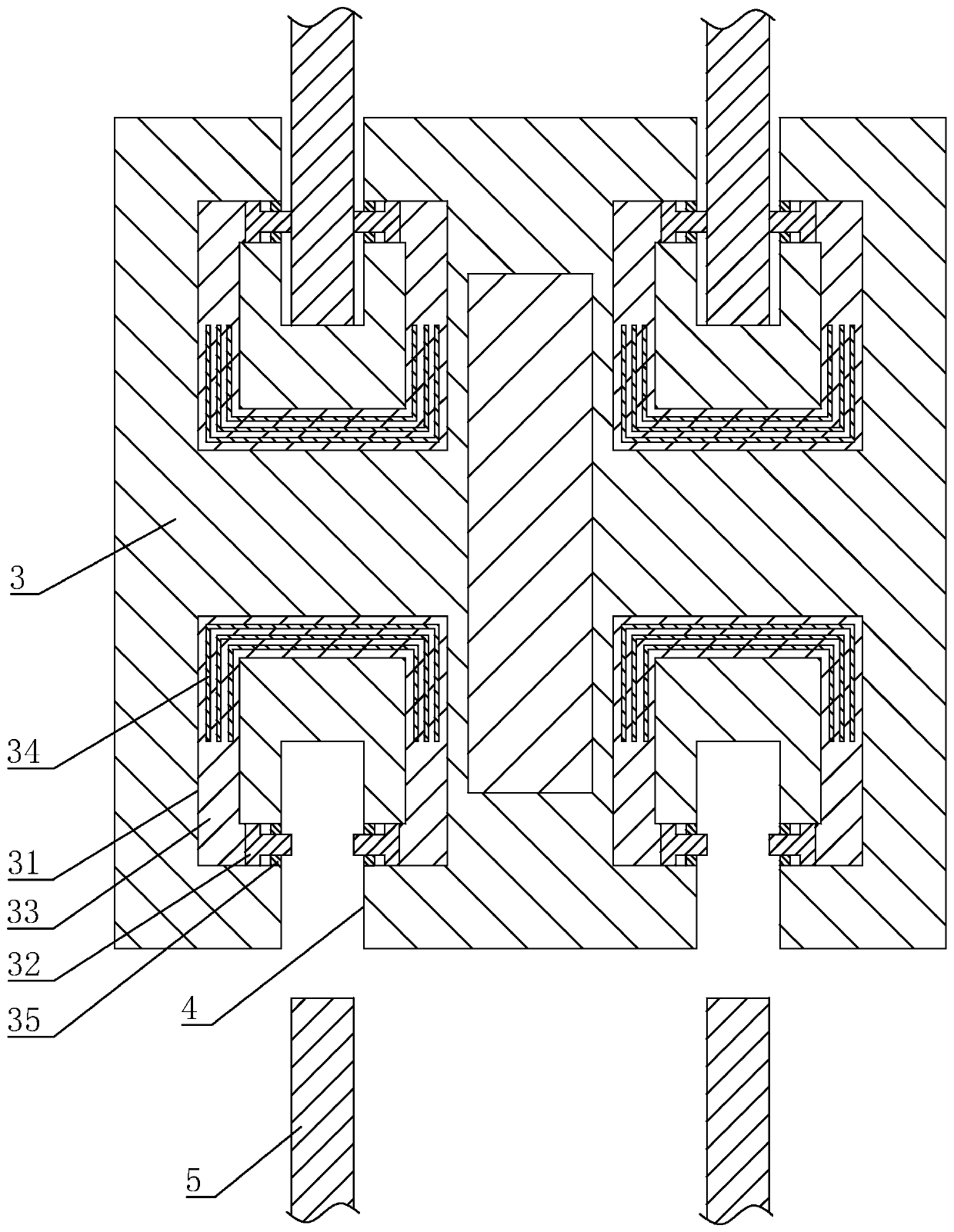

[0033] Such as figure 1 and figure 2 As shown, the corner pillar 1 is composed of two symmetrically arranged s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com