A test section for studying burst failure of annular fuel cladding

A fuel cladding and test section technology, applied in the direction of reducing greenhouse gases, climate sustainability, reactors, etc., can solve the problem of the inability to simulate the gas environment on the inner and outer surfaces of the annular fuel element cladding, and the inability to realize the deformation measurement of the inner and outer surfaces of the annular cladding, etc. low cost, easy installation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

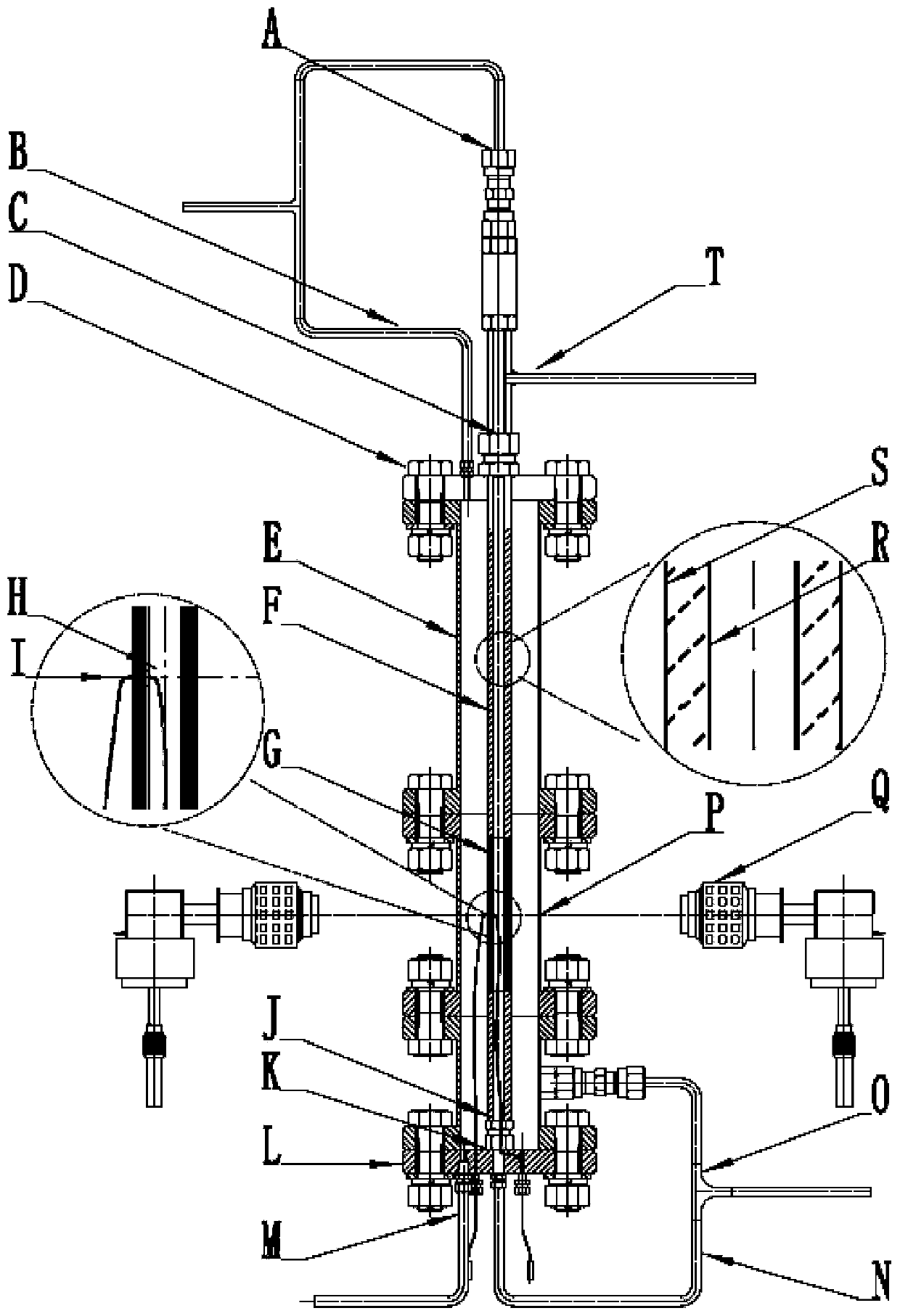

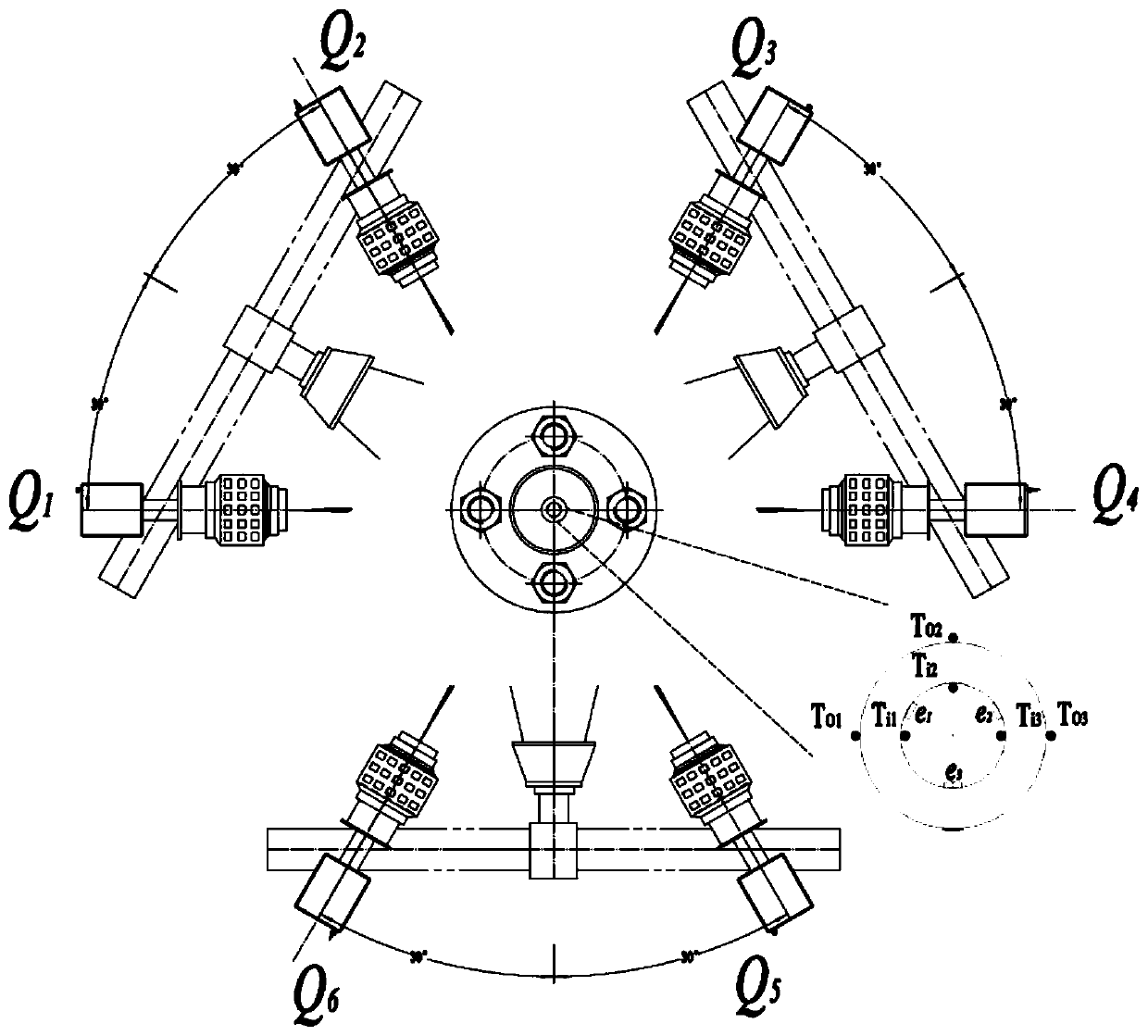

[0024] Such as figure 1As shown, a test section for studying the blasting failure of annular fuel cladding, including the inner cladding tube R and the outer cladding tube S of the annular fuel element, the annular molybdenum F between the inner cladding tube R and the outer cladding tube S and the annular electric current The heating element G, the temperature and strain measuring point H on the surface of the inner cladding tube R, the temperature measuring point I on the surface of the outer cladding tube S, the upper part of the inner cladding tube R and the outer cladding tube S are provided with an air inlet for high temperature and high pressure gas in the cladding T, the upper part of the inner cladding tube R and the outer cladding tube S is provided with a sealing gland C, and the bottom is provided with a supporting base L for supporting the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com