Disk monitoring system and method thereof

A monitoring system, a technology for loading trays, applied in conveyor control devices, welding equipment, manufacturing tools, etc., can solve problems such as inability to monitor trays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

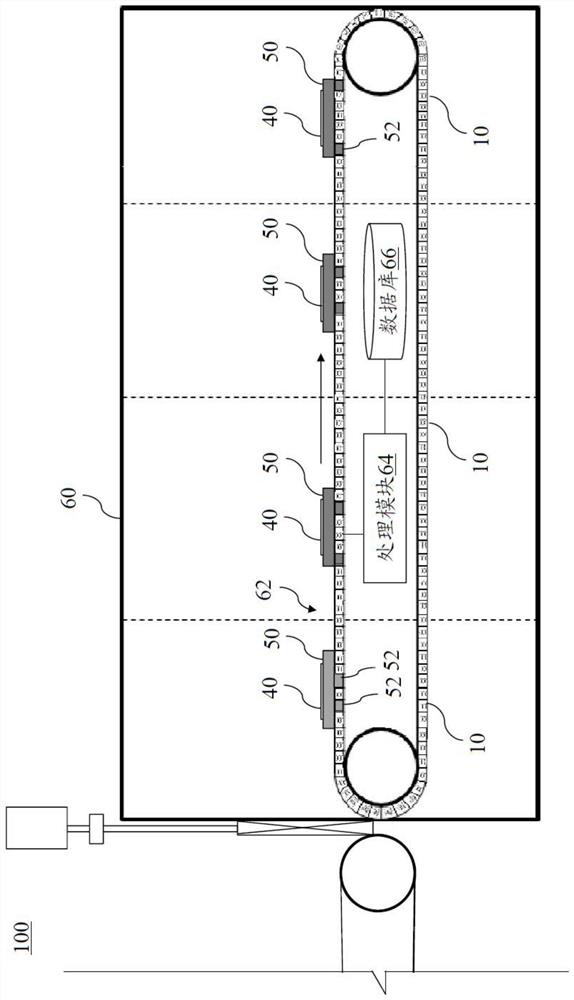

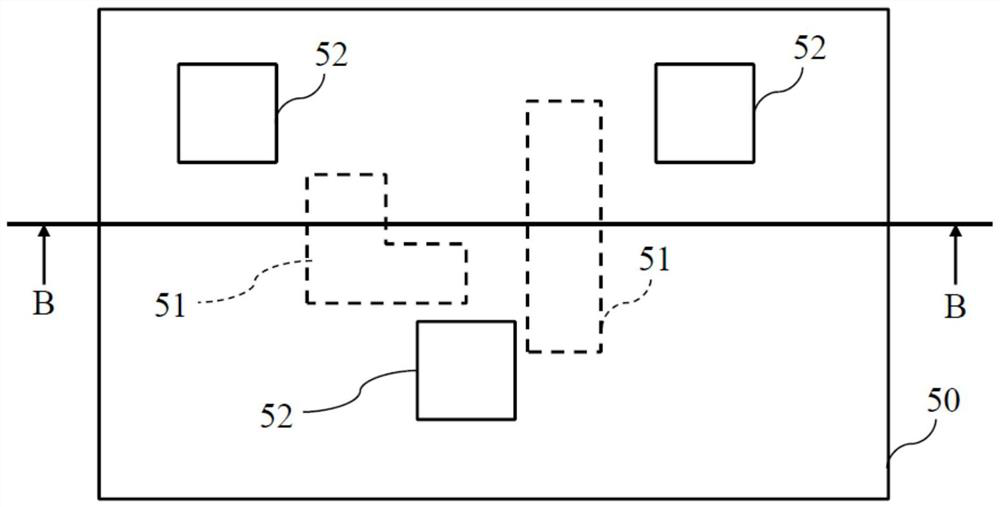

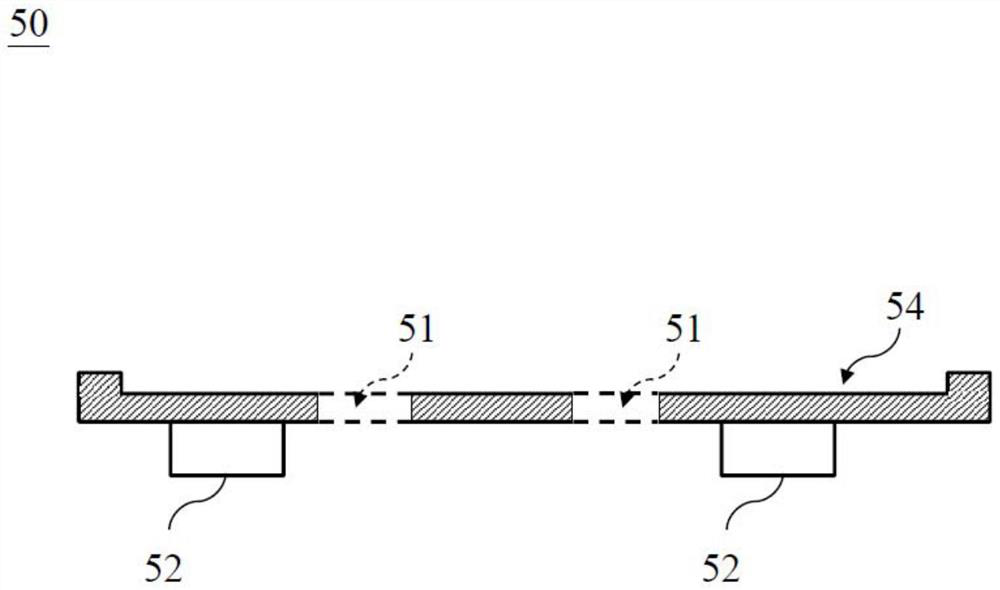

[0036] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

[0037] Before explaining the disc monitoring system and its method disclosed in the present invention, the nouns defined in the present invention will be described first. The processing modules included in the disc monitoring system of the present invention can be implemented in various ways, including software, hardware, firmware or any combination thereof. The technology presented in the implementation uses software or firmware that can be stored on a machine-readable storage medium, such as: read only memory (ROM), random access memory (RAM), magnetic disk storage medium, optical storage medium, flash memory device, etc. , and may be executed by one or more general-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com