Elastic strip flying-proof structure device for bolt-free fastener

A technology without bolts and elastic strips, applied in the direction of fixing rails, roads, buildings, etc., can solve problems such as failure, damage of protective sleeves, weakening of anti-flying functions, etc., and achieve fewer structural parts, high installation efficiency, material cost and construction low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

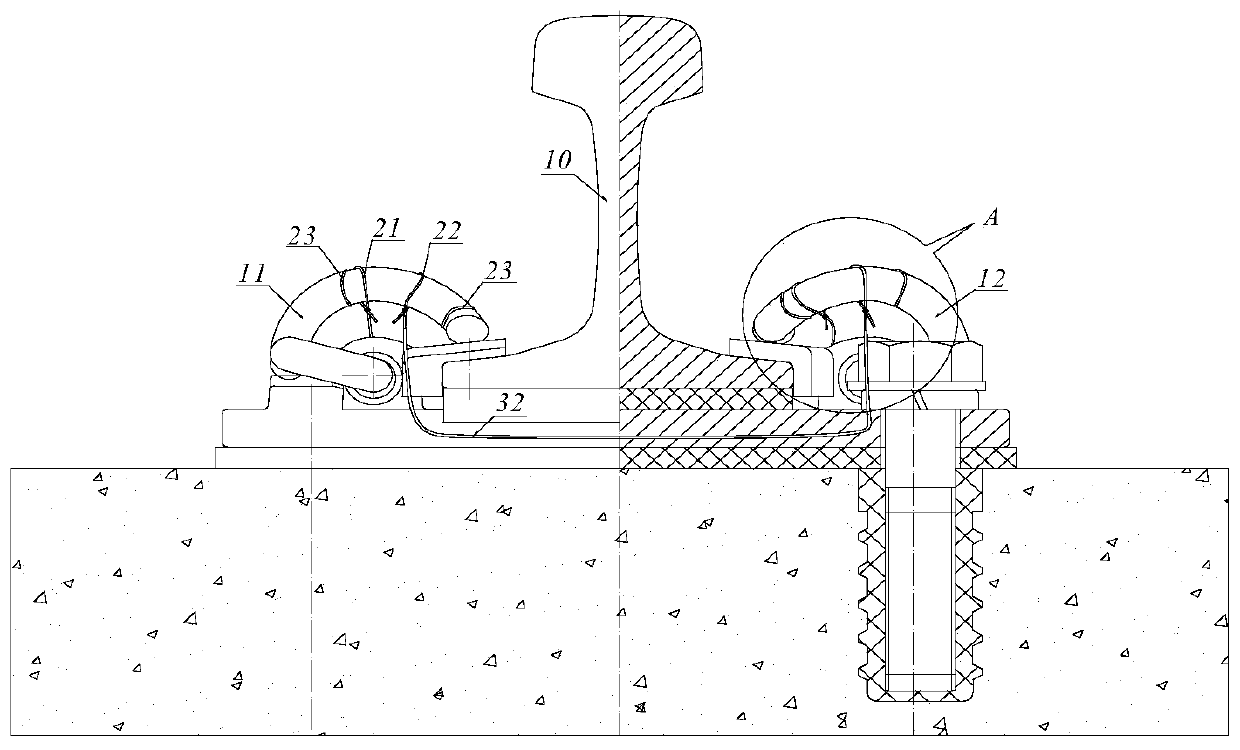

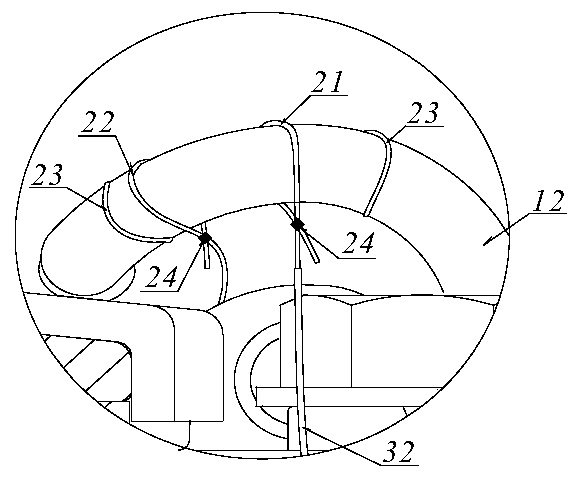

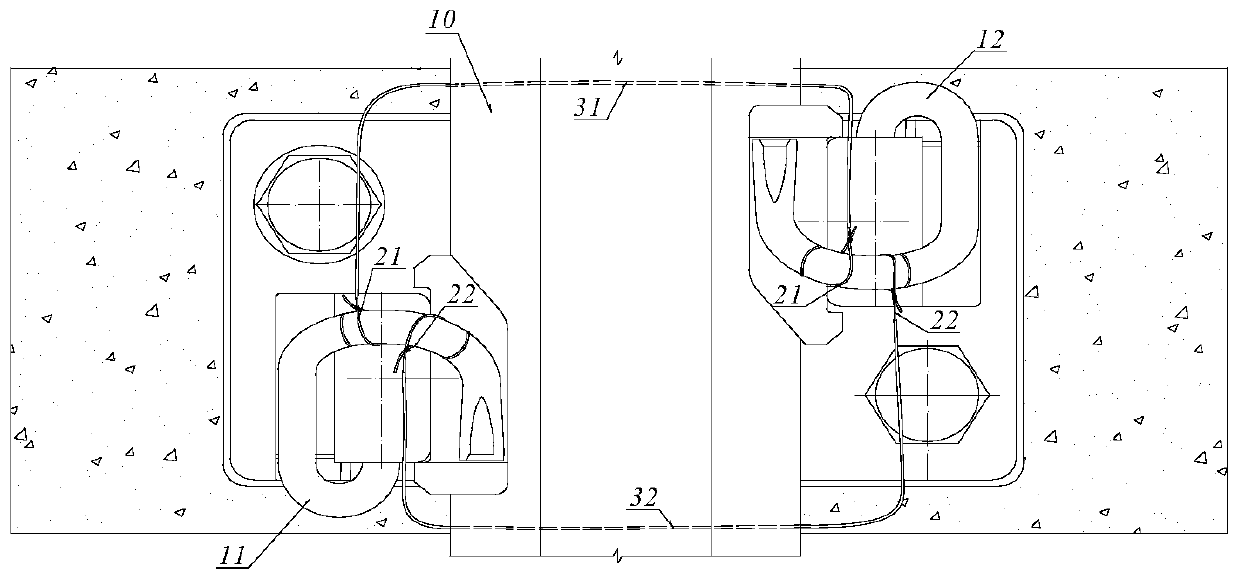

[0024] refer to figure 1 and image 3 , a spring anti-flying structural device for boltless fasteners according to the present invention includes a first e-shaped spring 11 and a second e-shaped spring 12 located on both lateral sides of the rail 10 . The first steel wire rope 21 and the second steel wire rope 22 that pass through the rail 10 are respectively arranged on both sides of the large arc of the front arch of the first e-shaped elastic strip 11 and the second e-shaped elastic strip 12. The first steel wire rope 21 and the second steel wire rope The two ends of 22 are respectively bound and connected with the first e-shaped elastic strip 11 and the front arch large arc position of the second e-shaped elastic strip 12 to form a self-locking system. It can ensure that the anti-flying function of the clip is effective, whether the clip on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com