An environment-friendly and dust-reducing construction rammer

A rammer and construction technology, applied in the field of construction rammers, can solve the problems of polluting the construction site environment, not being environmentally friendly, and raising a lot of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

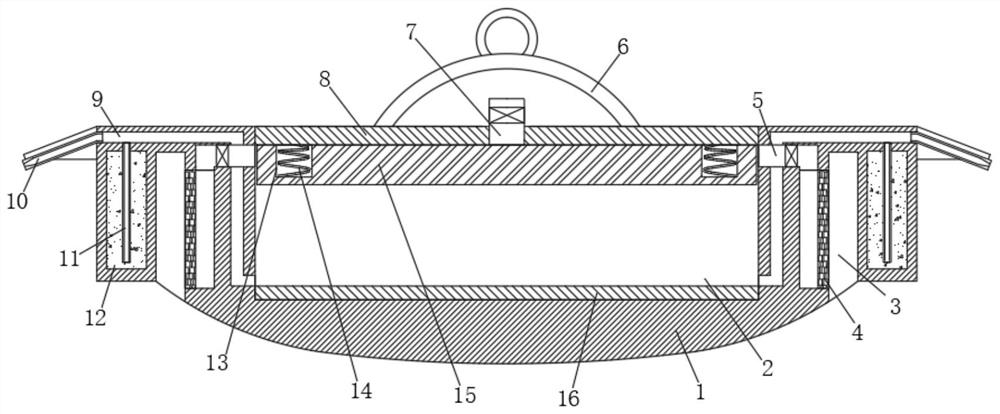

[0019] refer to figure 1 , an environment-friendly and dust-reducing construction rammer, comprising a rammer body 1, the upper end of the rammer body 1 is provided with a chute 2, the inner thread of the chute 2 is connected with a sealing plate 8, and the upper end of the sealing plate 8 is fixedly connected with a traction rope 6. There is a counterweight plate 15 that can slide up and down in the chute 2. The counterweight plate 15 divides the interior of the chute 2 into a negative pressure chamber and a positive pressure chamber arranged up and down. There are two symmetrically arranged on the counterweight plate 15. Mounting hole 13, the first tension spring 14 is arranged in the mounting hole 13, the two ends of the first tension spring 14 are respectively fixedly connected on the inner bottom wall of the sealing plate 8 and the mounting hole 13, and the lower end surface of the rammer body 1 is provided with There is a ring-shaped dust suction port 3, and the dust suc...

Embodiment 2

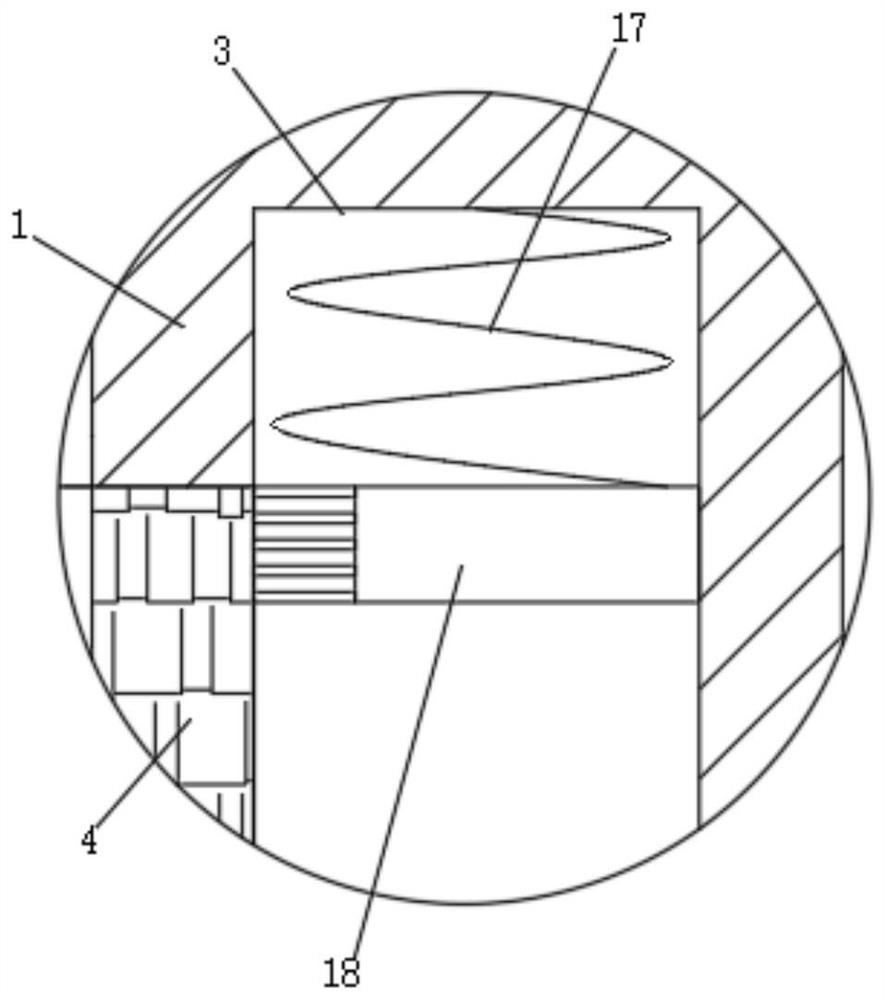

[0026] refer to figure 2 The difference between embodiment two and embodiment one is that in this embodiment, a cleaning mechanism for cleaning the filter screen 4 is provided in the dust suction port 3, and the cleaning mechanism includes an annular ring that is arranged in the dust suction port 3 and can move up and down. plate 18, the upper end surface of the annular plate 18 is fixedly connected with a plurality of second extension springs 17 along its circumferential direction at equal intervals, and the other end of the second extension spring 17 is fixedly connected on the inner top wall of the dust suction port 3, and the annular plate 18 The side walls close to the filter screen 4 are evenly distributed with bristles in contact with the surface of the filter screen 4 .

[0027] When the tamper body 1 falls and hits the ground, the annular plate 18 moves downward due to inertia, and then cleans the surface of the filter screen 4 through the bristles to remove the dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com