Fireproof and compressive cable

A technology for cables and cable core wires, applied in the field of fire-resistant and compression-resistant cables, can solve the problems of complex and useless outer protective layer structure, and achieve the effects of good heat dissipation performance, increased fire resistance performance, and good compression resistance and buffering capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

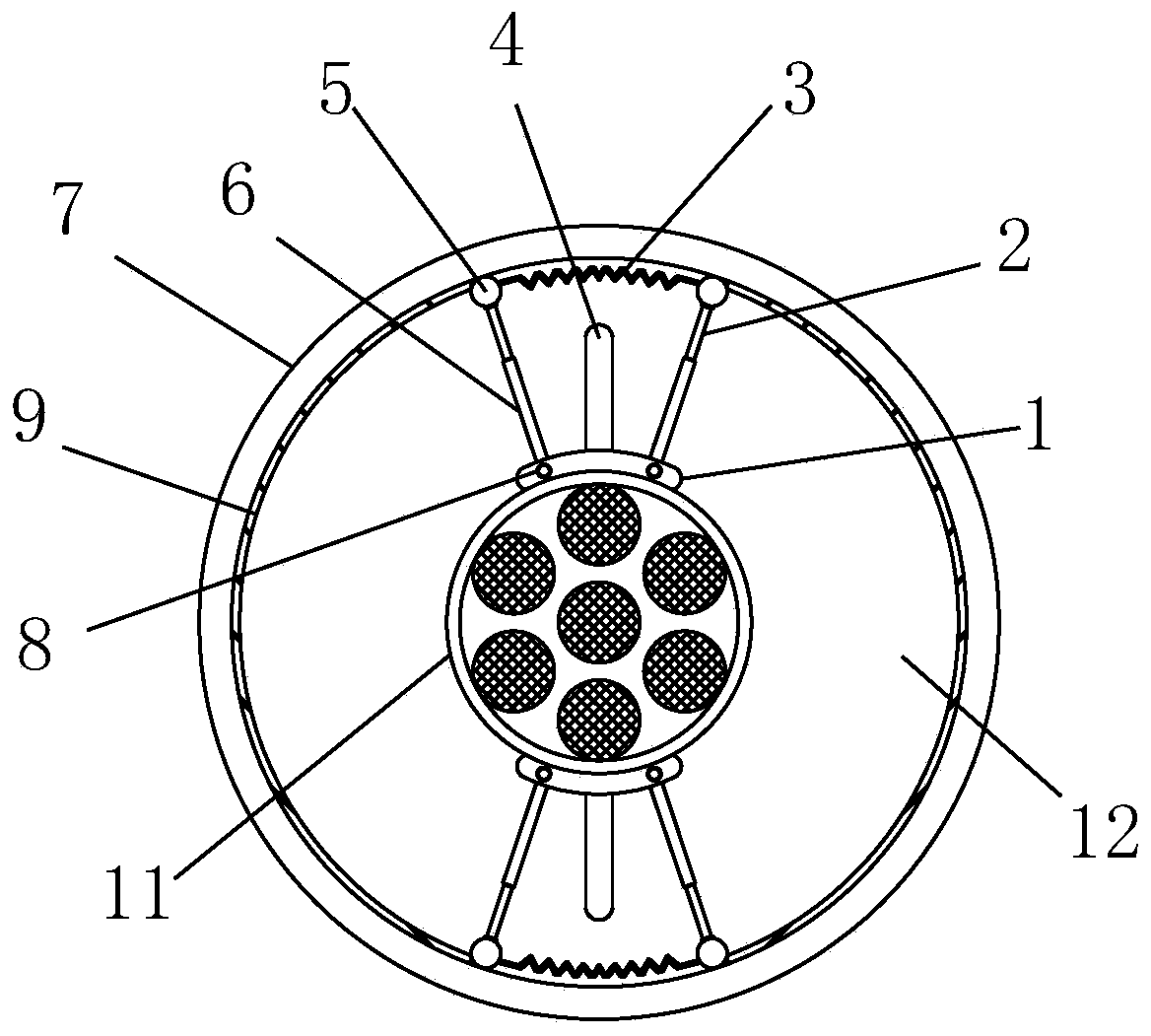

[0016] like figure 1 As shown, the fire-proof and compression-resistant cable includes a cable outer protective layer 7, and the inner portion of the cable outer protective layer 7 has a cable installation cavity 12, and the cable core wire 11 is arranged in the cable installation cavity 12, and the outer opposite surface of the cable core wire 11 An arc-shaped convex portion 1 is provided respectively, and the arc-shaped convex portion 1 extends along the length direction of the cable core wire 11;

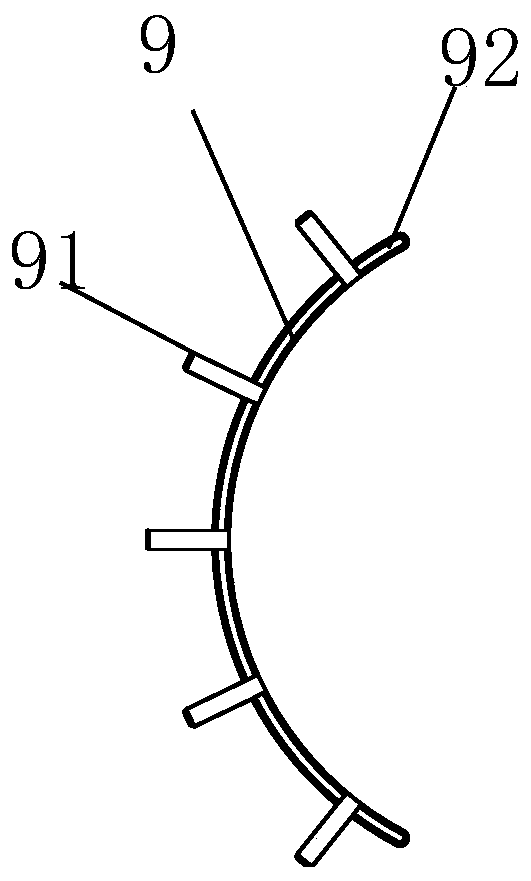

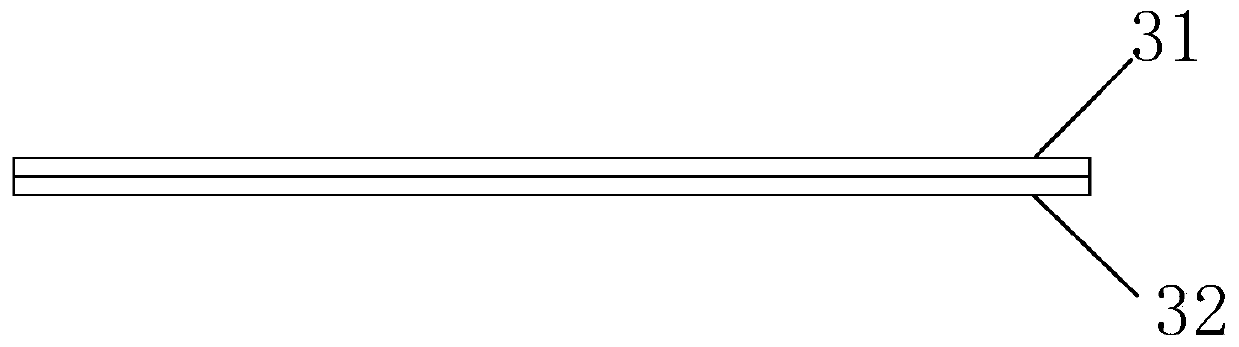

[0017] The two sides of arc-shaped convex part 1 are equidistantly provided with more than one turning groove (not shown), and a rotating shaft hole is respectively arranged on both sides of the turning groove inner wall, and a telescopic rod is all loaded into each turning groove, and the bottom of the telescopic rod A rotating shaft 8 is arranged on both sides respectively, and a torsion spring (not shown) is set on the rotating shaft 8. The rotating shaft 8 is elastically inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com