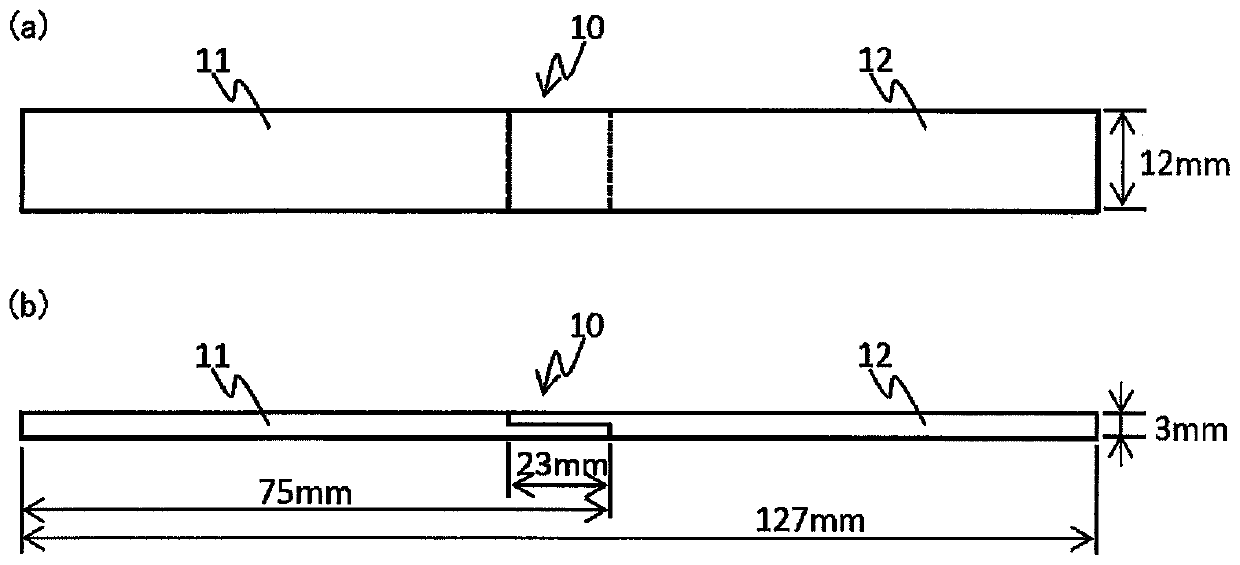

Molded article and method for manufacturing same

A manufacturing method, technology of molded body, applied in the direction of coating, etc., can solve the undisclosed problems, and achieve the effect of excellent bonding strength, damage resistance and coloring resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

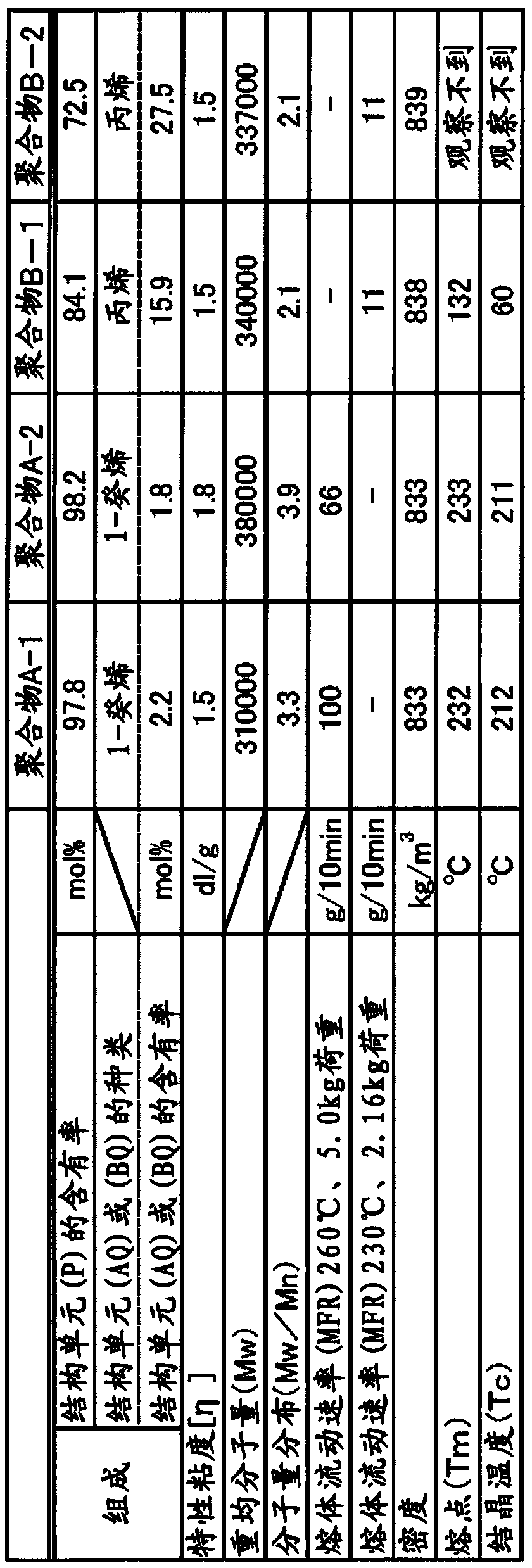

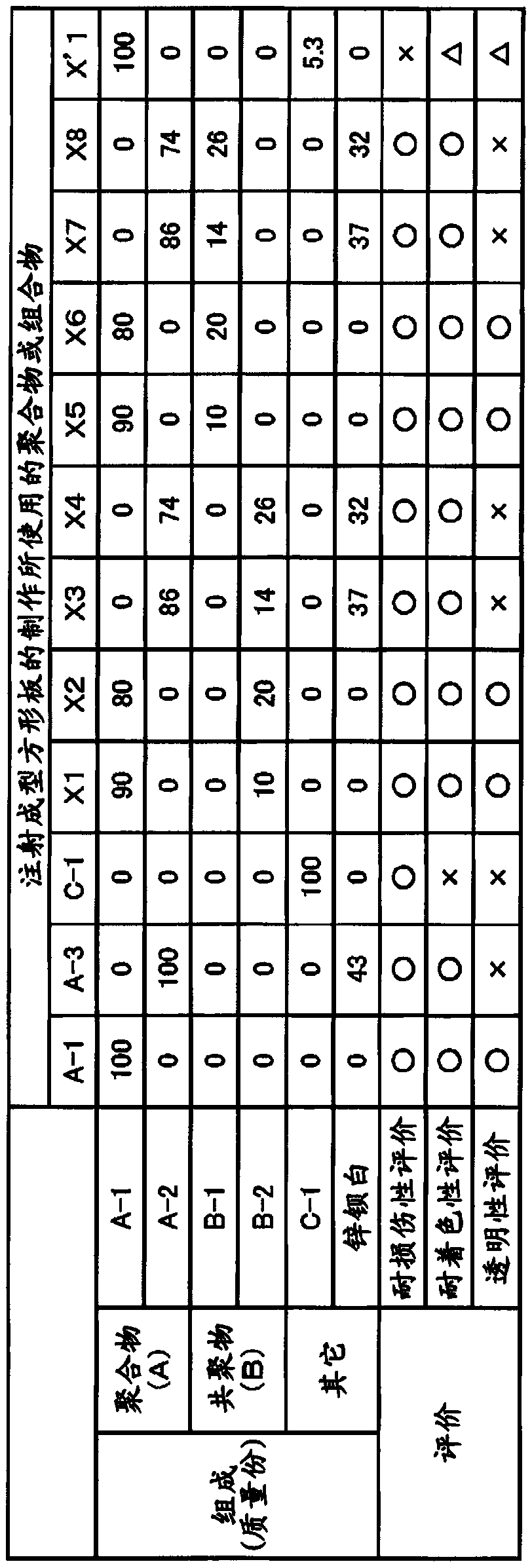

[0130] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to the following Example unless the summary is exceeded.

[0131] [Measuring methods of various physical properties]

[0132] The methods used for measuring various physical properties of the polymers obtained in this example are shown below.

[0133] (1) Composition

[0134] By adopting the above 13 The C-NMR measurement method determines the composition of the polymer.

[0135] (2) Intrinsic viscosity [η]

[0136] The intrinsic viscosity [η] measured at 135° C. in a decahydronaphthalene solvent was determined by the method described above using an Ubbelohde viscometer.

[0137] (3) Weight average molecular weight (Mw) and molecular weight distribution (Mw / Mn)

[0138] Liquid chromatography: ALC / GPC 150-C plus type (differential refractometer detector integrated type) manufactured by Waters was used, and GMH6-HT × 2 and GMH6-HTL × 2 manufactured by Tosoh Co....

Synthetic example 1

[0151] ~Synthesis of Polymer B-1~

[0152] Into a 1.5 L capacity SUS autoclave with stirring blades fully replaced with nitrogen, 300 ml of n-hexane (dried product dried on activated alumina under a dry nitrogen atmosphere) was charged at 23°C. After mixing with 450 ml of 4-methyl-1-pentene, 0.75 ml of a 1.0 mmol / ml toluene solution of triisobutylaluminum (TIBAL) was charged, and stirring was started.

[0153] Next, the autoclave was heated until the inner temperature became 60° C., and pressurized with propylene so that the total pressure (gauge pressure) became 0.19 MPa.

[0154] Next, a pre-prepared mixture containing 1 mmol of methylaluminoxane and 0.01 mmol of diphenylmethylene (1-ethyl-3-tert-butyl-cyclopentadienyl) (2 , 0.34ml of a toluene solution of 7-di-tert-butylfluorenyl) zirconium dichloride was injected into the autoclave with nitrogen pressure to start the polymerization reaction. During the polymerization reaction, the temperature was adjusted so that the inn...

Synthetic example 2

[0157] ~Synthesis of Polymer B-2~

[0158] 750 ml of 4-methyl-1-pentene was charged at 23° C. into a 1.5-liter SUS autoclave with a capacity of 1.5 liters that had been fully replaced with nitrogen. 0.75 ml of a 1.0 mmol / ml toluene solution of triisobutylaluminum (TIBAL) was charged into the autoclave, and stirring was started.

[0159]Next, the autoclave was heated to an inner temperature of 60° C., and pressurized with propylene so that the total pressure became 0.13 MPa (gauge pressure). Next, pre-prepared methylaluminoxane and diphenylmethylene (1-ethyl-3-tert-butyl-cyclopentadienyl) (2,7-di-tert- 0.34 ml of a toluene solution of 0.01 mmol of butylfluorenyl) zirconium dichloride was injected into the autoclave with nitrogen pressure to start polymerization. During the polymerization reaction, the temperature was adjusted so that the inner temperature of the autoclave was 60°C. Sixty minutes after the start of the polymerization, 5 ml of methanol was pressurized into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com