Nuclear power station pool filter screen and disassembly method thereof

A technology for a nuclear power plant and a filter screen is applied in the field of a nuclear power plant pool filter screen and its disassembly and assembly, which can solve the problems of long time consumption, complicated operation, unreasonable filter screen structure setting, etc., and achieve the effect of reducing the stay time and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

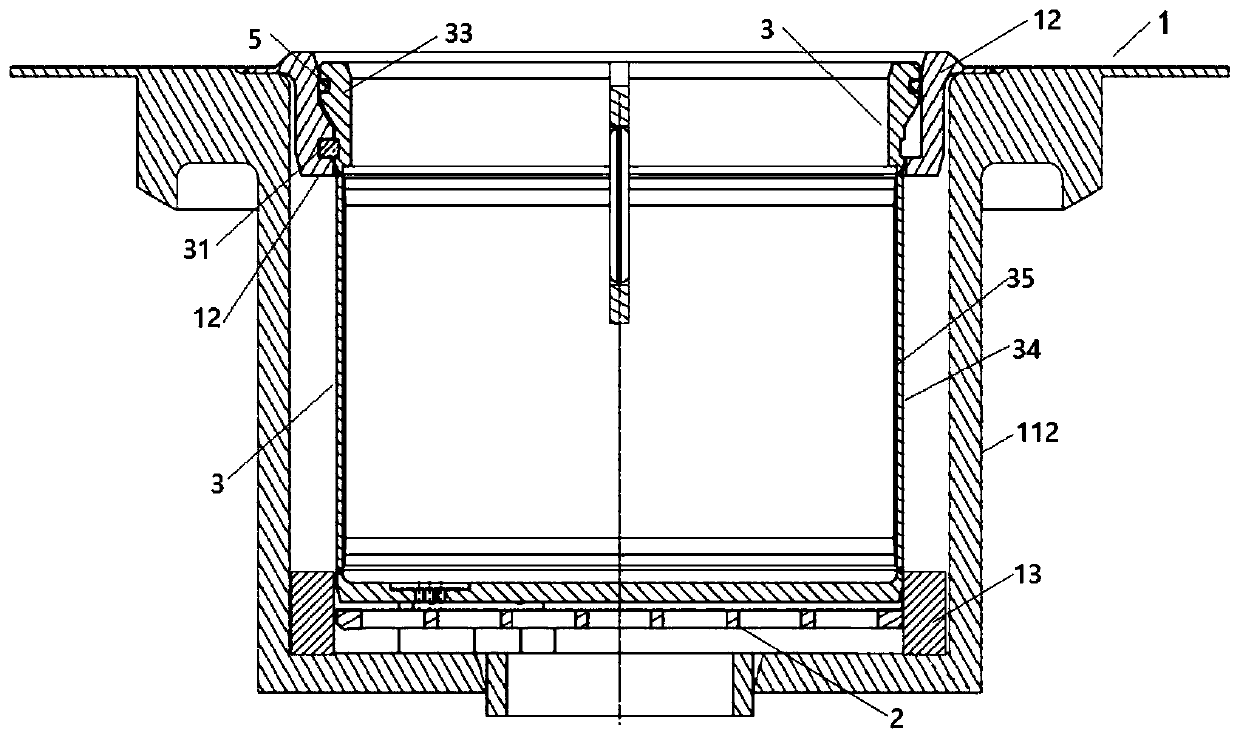

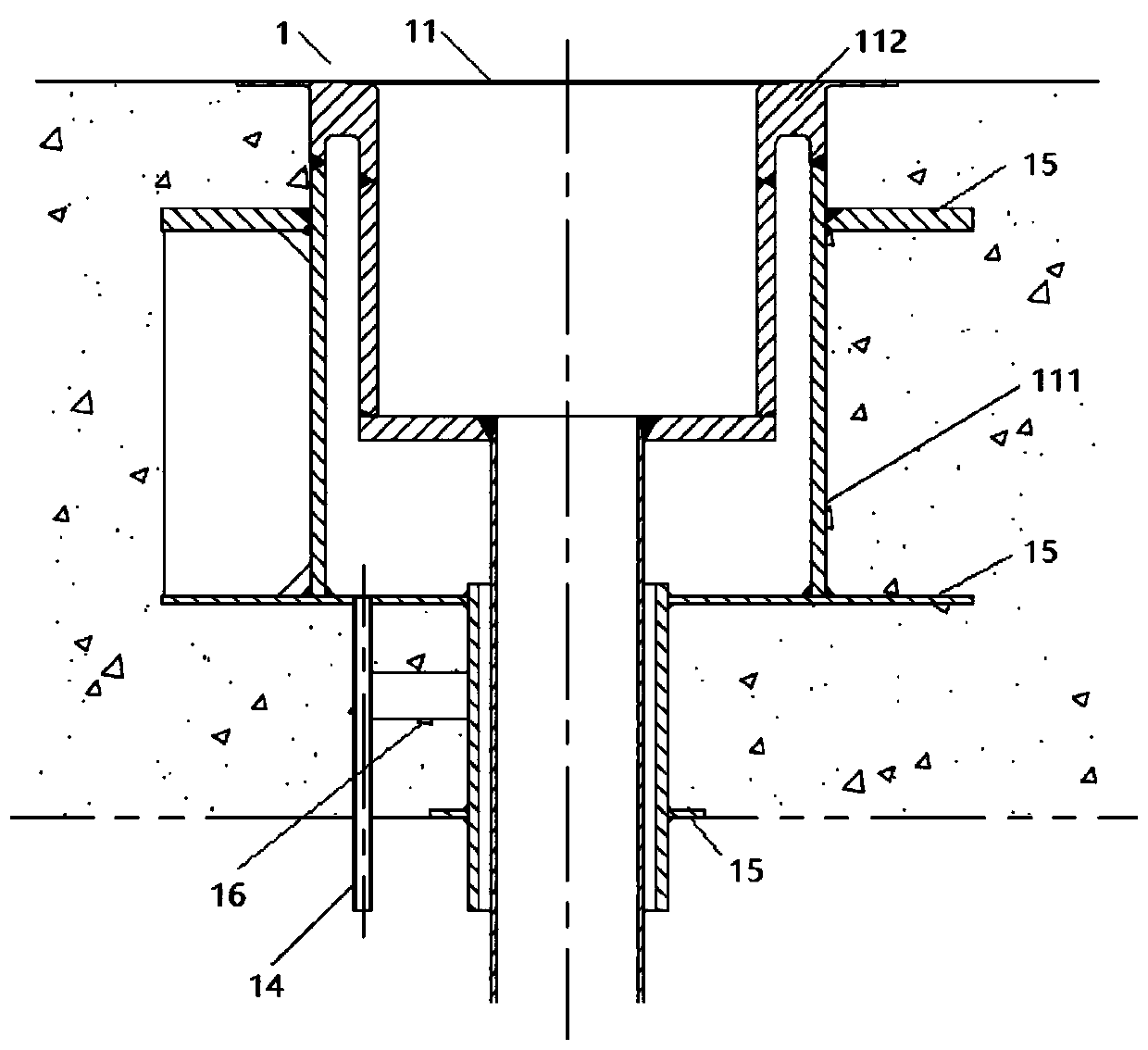

[0058] Embodiment 1. The embodiment of the present invention provides a nuclear power plant pool filter, see figure 1 and figure 2 , including a bushing assembly 1, which is arranged at the bottom of the pool and communicates with the refueling water tank inside the containment;

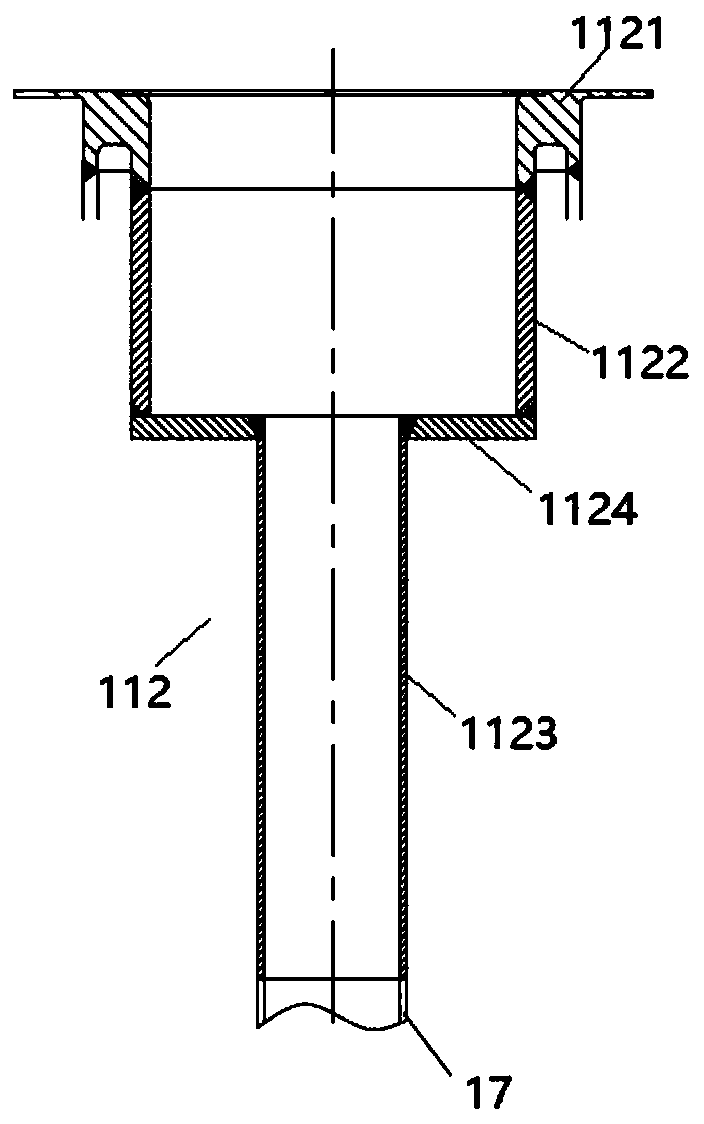

[0059] Coarse strainer 2, which is arranged at the bottom of the casing assembly 1, is used to filter debris in the pool; since the coarse strainer 2 works during unit operation, it prevents large debris from entering the PTR pipeline 17 ( see image 3 ), it is installed at the bottom of bushing assembly 1, and it does not need to be replaced during unit operation and refueling.

[0060] Fine filter 3, which is arranged on the top of the sleeve assembly 1, and is connected with the sleeve assembly 1 by rotation, is used to filter the hot spots in the pool; the fine filter 3 is only used when refueling Use it, remove it after refueling, and install it on the top of the bushing assembly 1, which is...

Embodiment 2

[0092] Embodiment 2, the present invention provides a kind of disassembly method of nuclear power plant pool filter net, comprises the following steps:

[0093] Before the pool is not filled with water, install the coarse filter 2 and the fine filter 3 on the bottom and top of the sleeve assembly 1 respectively, and the fine filter 3 and the sleeve assembly 1 are Rotary snap connection;

[0094] One end of the rope assembly 4 is connected with the fine filter screen 3, and the other end is placed on the top operating platform of the nuclear power plant pool;

[0095] After the pool is drained, the rope assembly 4 is pulled with force, so as to rotate and loosen the fastening connection between the fine filter 3 and the sleeve assembly 1, and extract the fine filter 3 from the pool.

[0096] Specifically, during refueling overhaul and before the pool is not filled with water, the operator enters the bottom of the pool through a ladder, installs the fine filter 3 on the bushing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com