Hydrodynamic noise silencer

A hydrodynamic and muffler technology, applied in the direction of pipes/pipe joints/fittings, mechanical equipment, pipe components, etc., can solve problems such as attenuation of hydrodynamic noise, attenuate hydrodynamic noise, reduce underwater radiated noise, and improve acoustic stealth. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will now be described in conjunction with the accompanying drawings, and the present invention is not limited to the following embodiments.

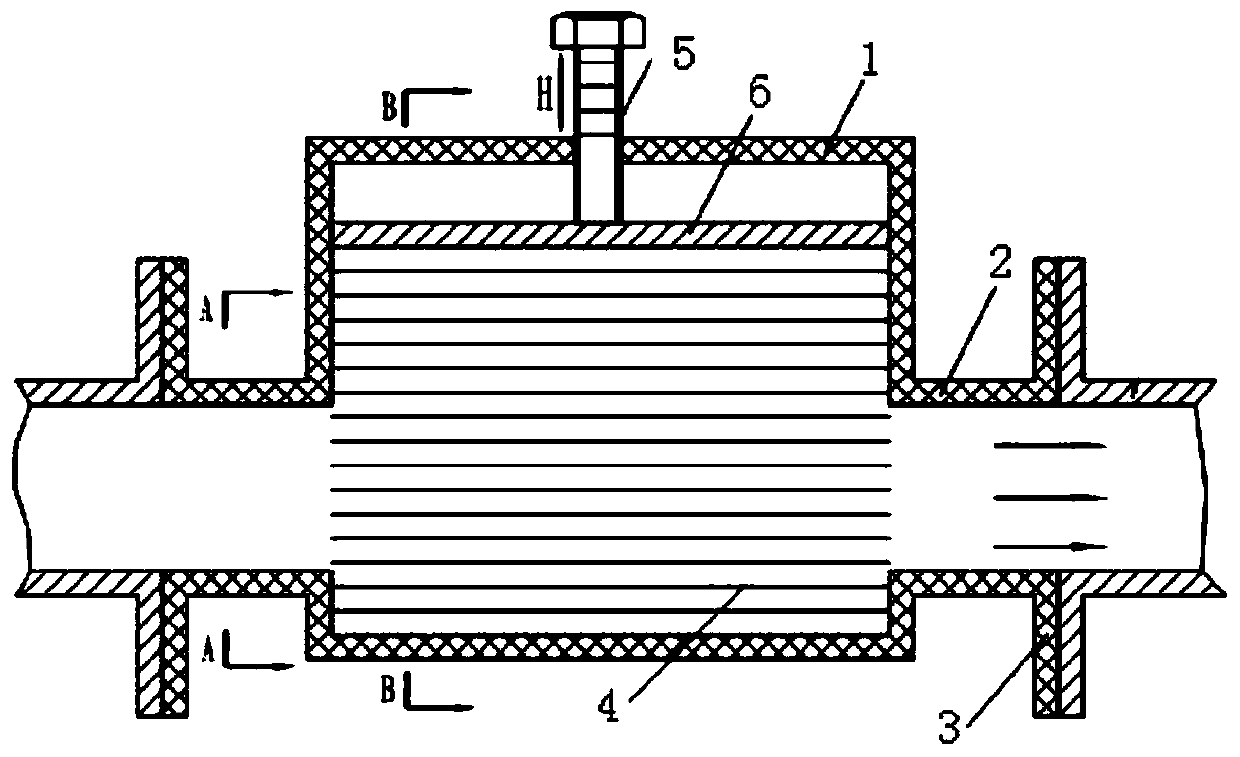

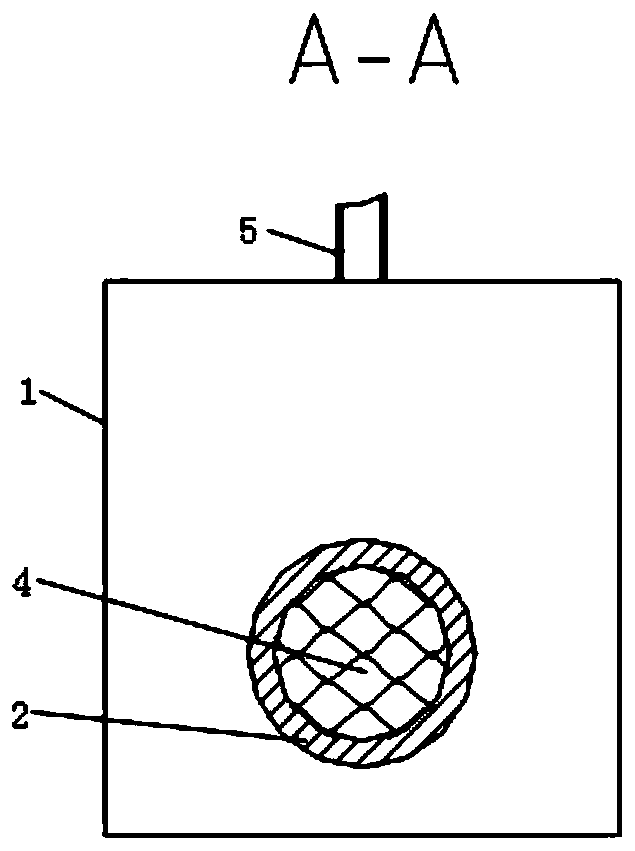

[0018] like Figure 1-Figure 3 As shown, a fluid dynamic noise muffler includes a muffler housing 1, a muffler assembly and a pressure adjustment device, the muffler assembly is arranged in the muffler housing, the pressure adjustment device is connected with the muffler housing, and is connected with the muffler assembly contact;

[0019] The muffler shell is a square structure, with connecting pipes 2 on the end faces on both sides, and connecting flanges 3 on the outer ends of the connecting pipes;

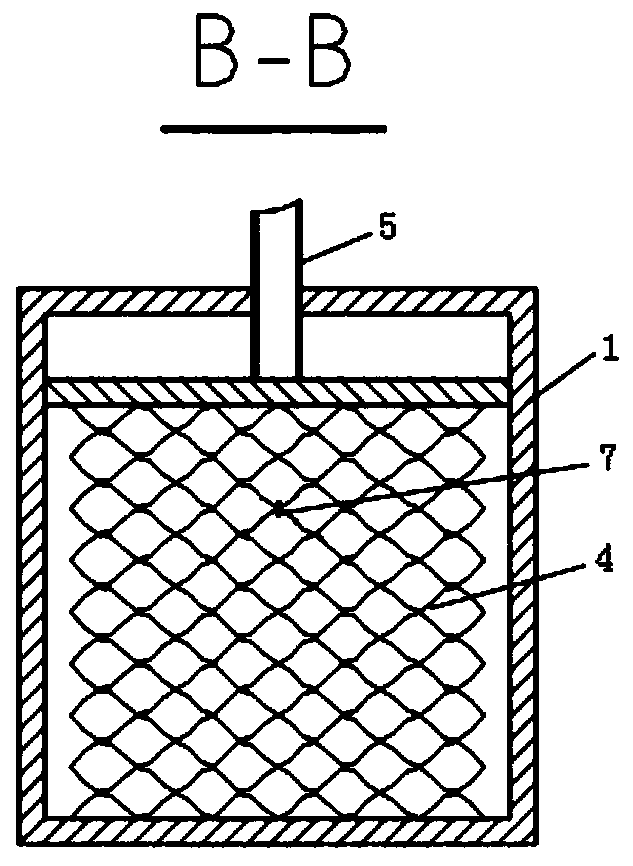

[0020] The muffler assembly includes a plurality of elastic corrugated plates 4, which are stacked up and down in the muffler shell, and the peaks and troughs of two adjacent elastic corrugated plates are arranged correspondingly one by one to form a grid end face;

[0021] The pressure re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com