Stack type low noise sea chest

A submarine valve box and low-noise technology, applied in ship propulsion, ship components, ships, etc., can solve the problems of reduced ship acoustic stealth performance, cavity vibration fatigue damage, unfavorable fluid-solid coupling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

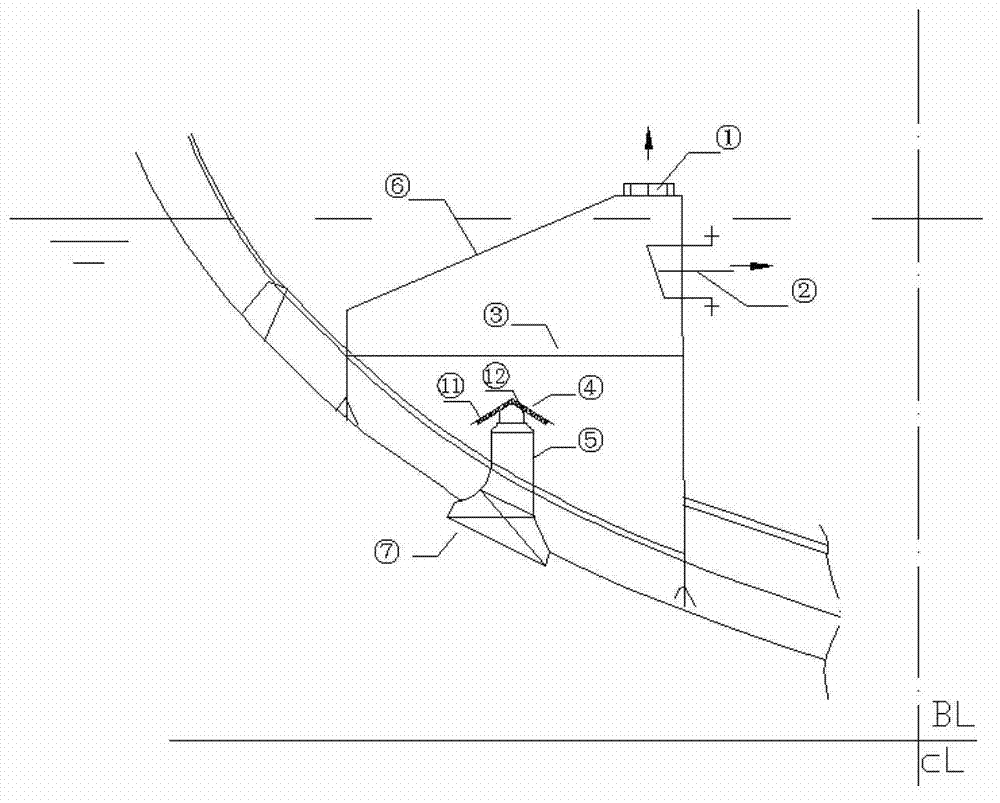

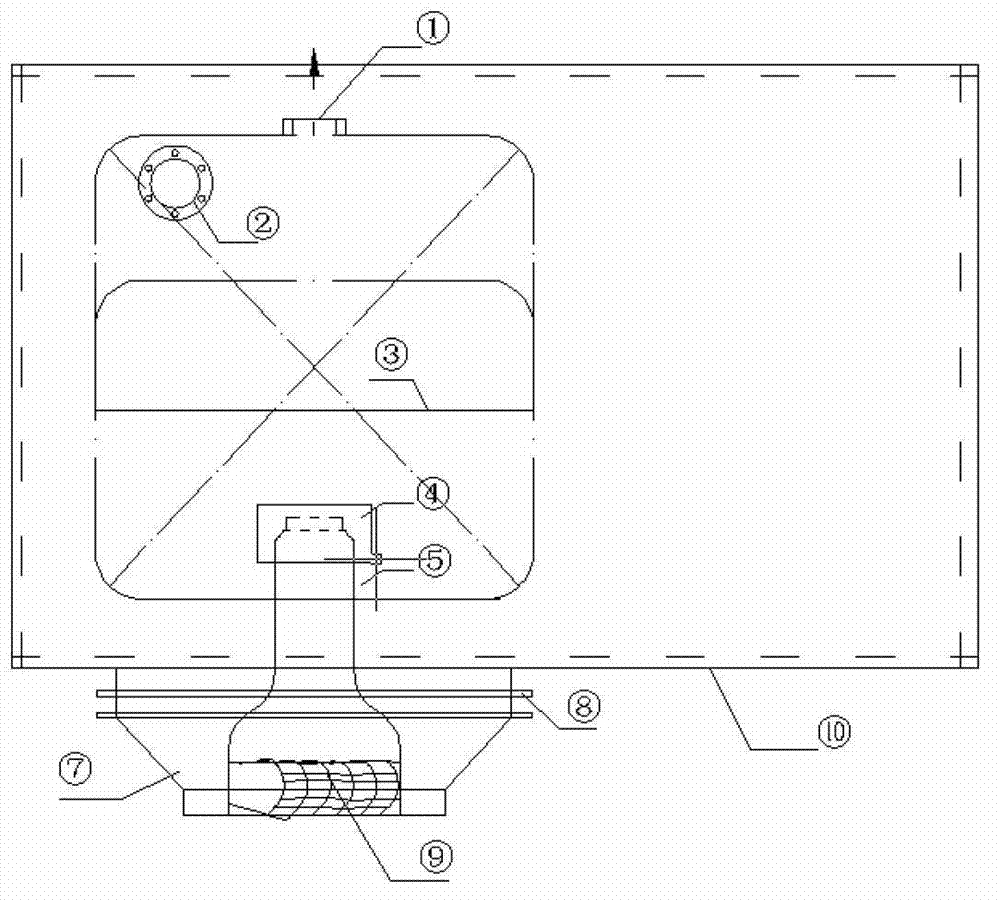

[0017] Below in conjunction with accompanying drawing example this invention is described in more detail:

[0018] The submarine valve box structure may be arranged at the position of the seawater main pipe at the bow, middle, and stern of the ship. The present invention will be described in more detail by taking the typical submarine valve box structure at the side of the middle part of the ship as an example:

[0019] The detachable inner concave grid piece 9 is connected with the cavity opening 7 of the rotating box through the pin shaft, which is convenient for disassembly; the isolation plate 5 of the partition box is welded on the inner bottom plate; the chimney-type baffle 4 and the isolation plate 5 of the partition box pass through 4 pillars 12 are connected and a certain gap is reserved; the inner side of the chimney baffle plate 4 is coated with anti-corrosion material 11; rows of gas-liquid separation holes are arranged on the horizontal partition plate 3 with holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com