Microbubble Noise Reduction Applicable to Ducted Propellers

A technology of micro-bubbles and ducted propellers, which is applied in transportation and packaging, ship propulsion, ship parts, etc., can solve the adverse effects of marine organisms, sound pollution of ships, etc., and achieve the goal of improving concealment, protecting the living environment, and reducing noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

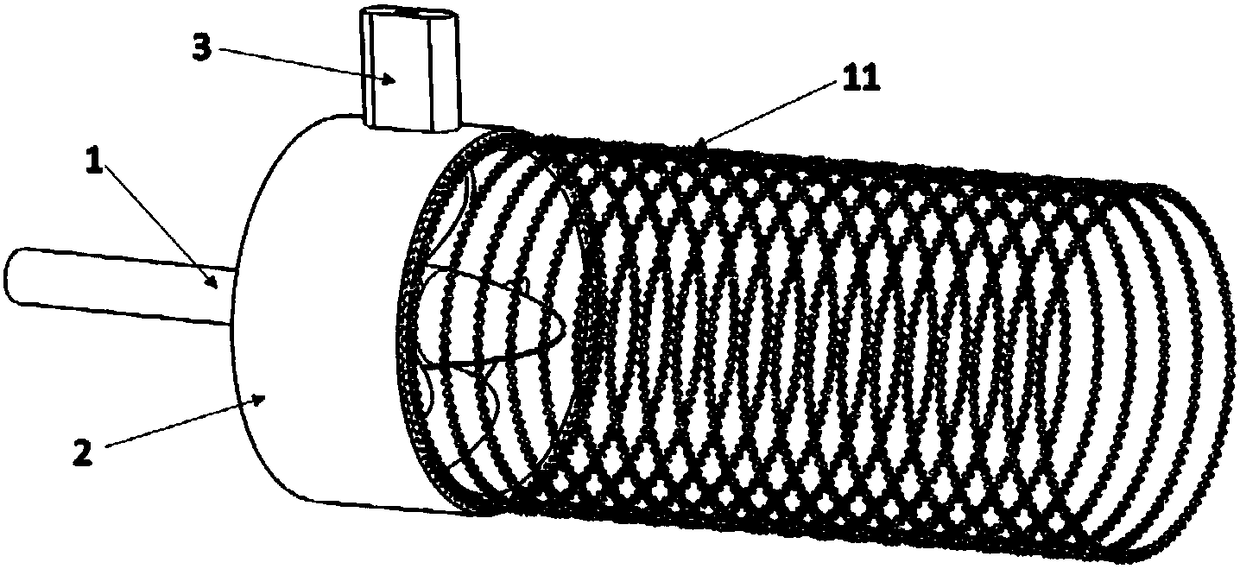

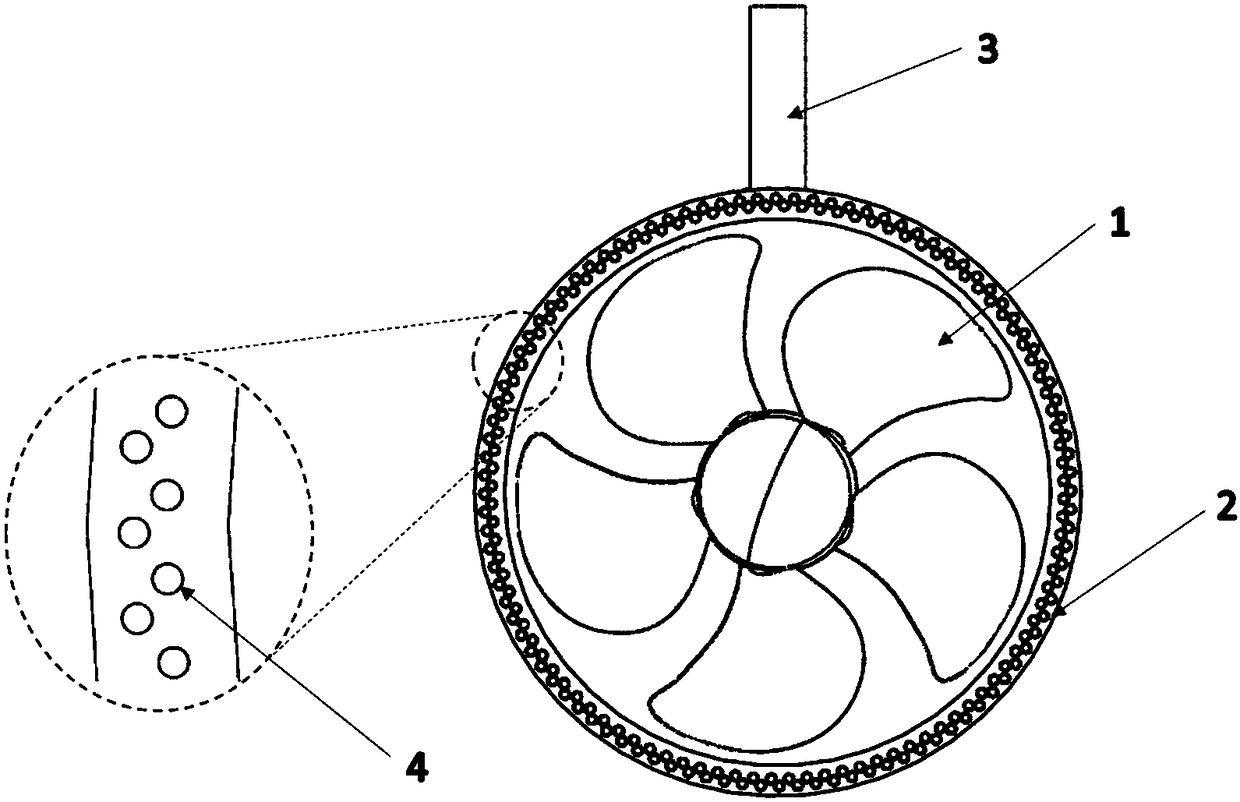

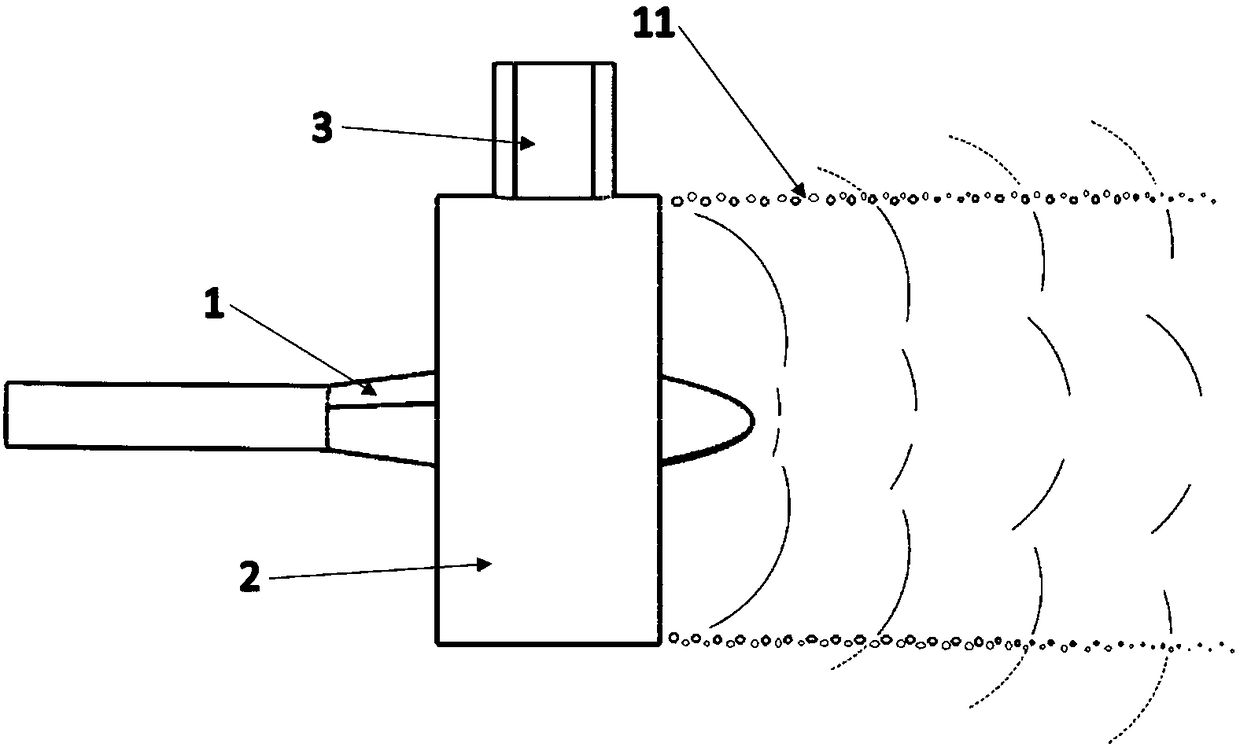

[0013] combine Figure 1 to Figure 5 , the present invention is a microbubble noise reduction device suitable for ducted propellers, mainly including ducted propellers, air supply pipelines and air compressors, wherein the ducted propellers include a propeller 1, a duct 2 and a duct support 3, and the trailing edge of the duct has two The small holes 4 with dense rings can generate a large number of microbubbles, thereby forming a gas-liquid mixture with a certain thickness. The gas supply pipeline includes the gas charging port 5, the gas supply pipeline 6, the pressure gauge 7 and two jet semi-rings 8, and the air pressure Machine comprises main parts such as adjustable high-pressure valve 9 and air storage tank 10. The air pipeline has two branches, and the air is input from the upper and lower ends of the two air jet half-rings o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com