A reciprocating underwater very low frequency sound source

A very low-frequency, reciprocating technology, applied in the field of underwater very low-frequency sound sources, can solve the problems of heavy electric rammer, unusable electric rammer, broken spring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples describe the present invention in more detail.

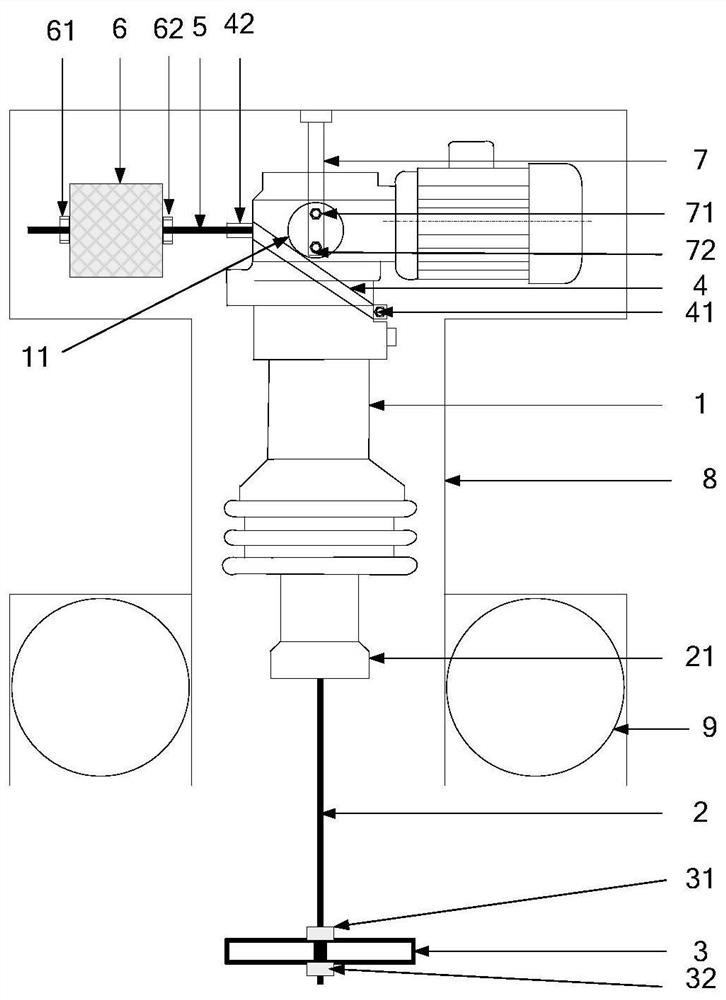

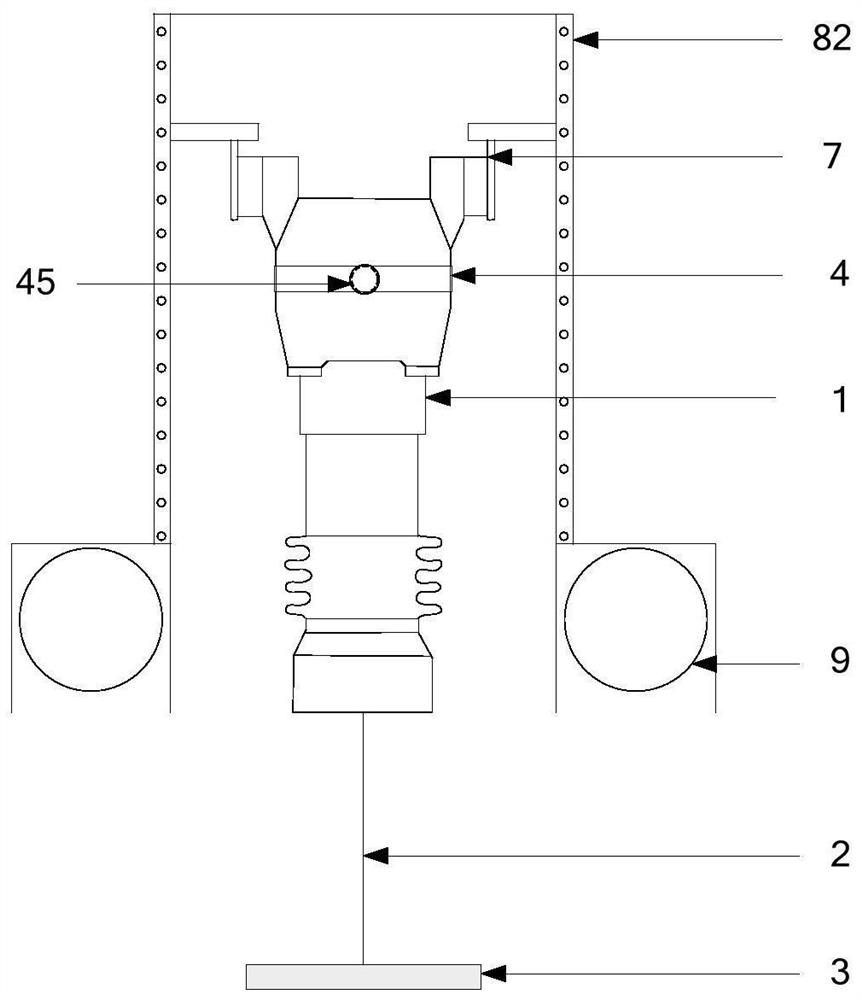

[0027] The underwater very low frequency sound source designed with a reciprocating mechanism of the present invention includes an electric rammer 1, an exciting rod 2, a piston 3, a clamp 4, a balance bar 5, a balance block 6, a support frame 7, a sound insulation cover 8, an inflatable Air bag 9, frequency converter. The electric rammer 1 removes the handrail and ramming plate, the bottom of the electric rammer 1 is connected to the excitation rod installation flange 21 of the excitation rod 2, the other end of the excitation rod 2 is connected to the piston 3, and the clamp 4 runs through the electric rammer 1 One end of the balance bar 5 is fixed on the fixture 4, and the other end is installed with a balance block 6. One end of the support frame 7 is fixed on the shock absorber 11 of the electric rammer 1, and the other end is fixed on the sound insulation cover 8. The sound cover 8 wraps the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com