Tyre tread for hgv trailer

A tread and trailer technology, used in heavy-duty tires, heavy-duty vehicles, tire treads/tread patterns, etc., can solve problems such as axial outer part wear, and achieve the effect of high mechanical rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

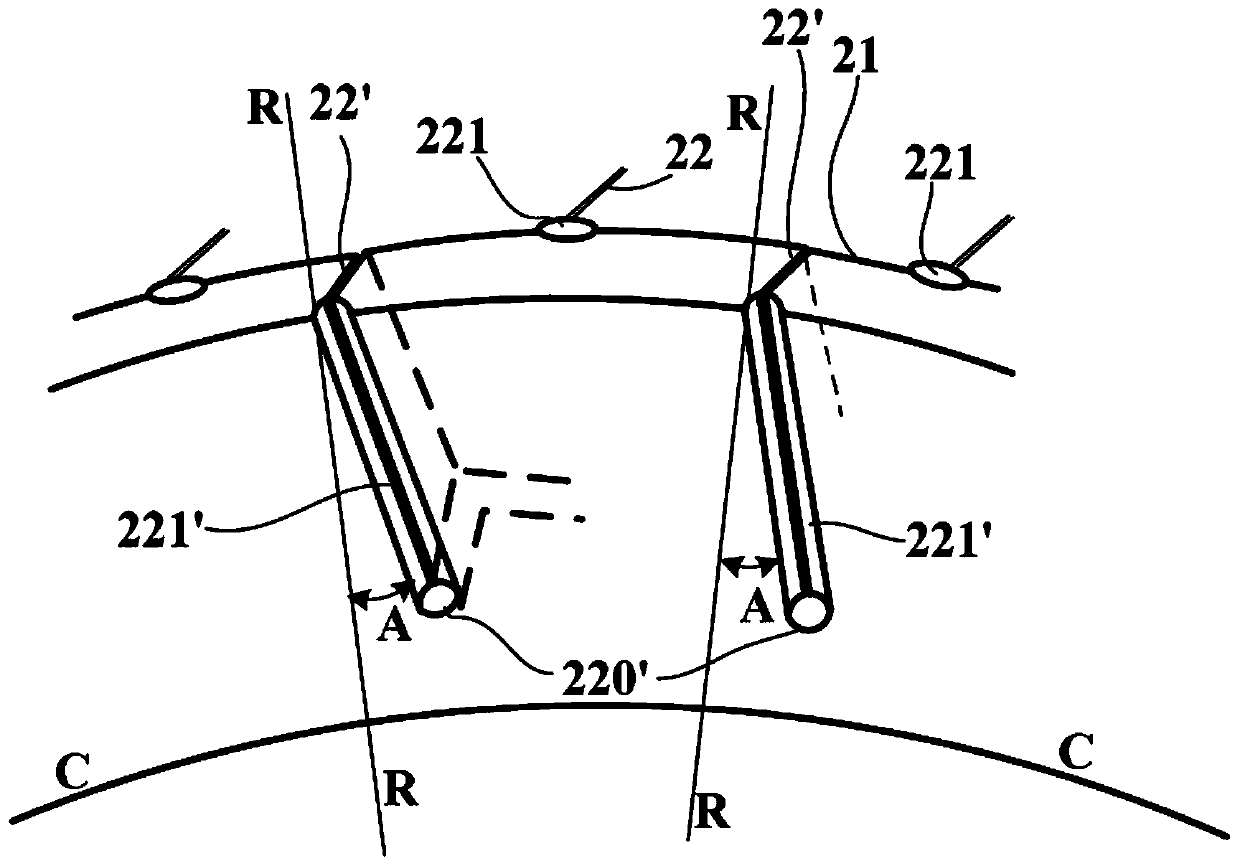

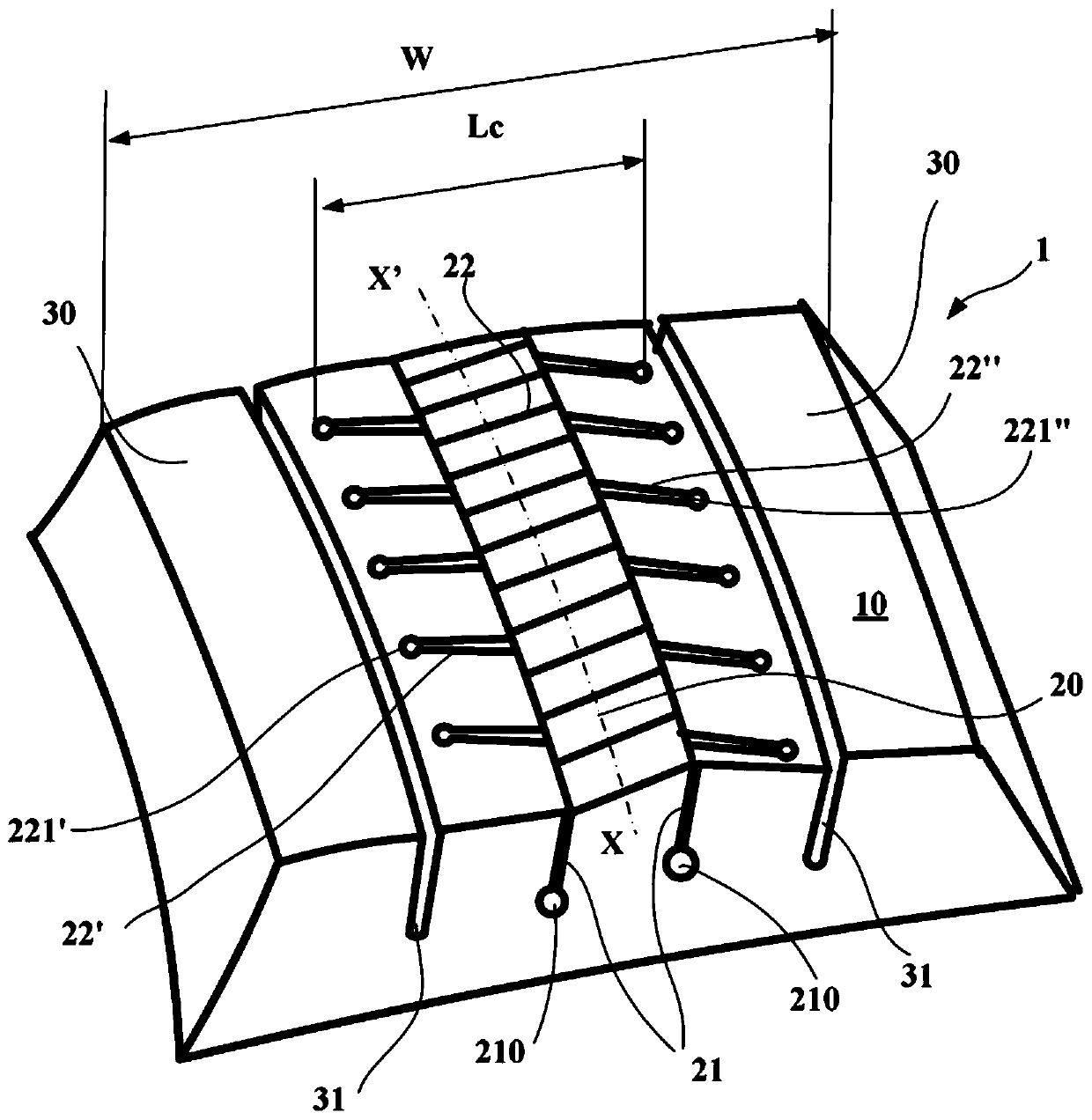

[0053] With respect to the figures accompanying this description, variants of the invention may be indicated using the same reference numerals, wherein these reference numerals designate elements of the same type (whether structural or functional).

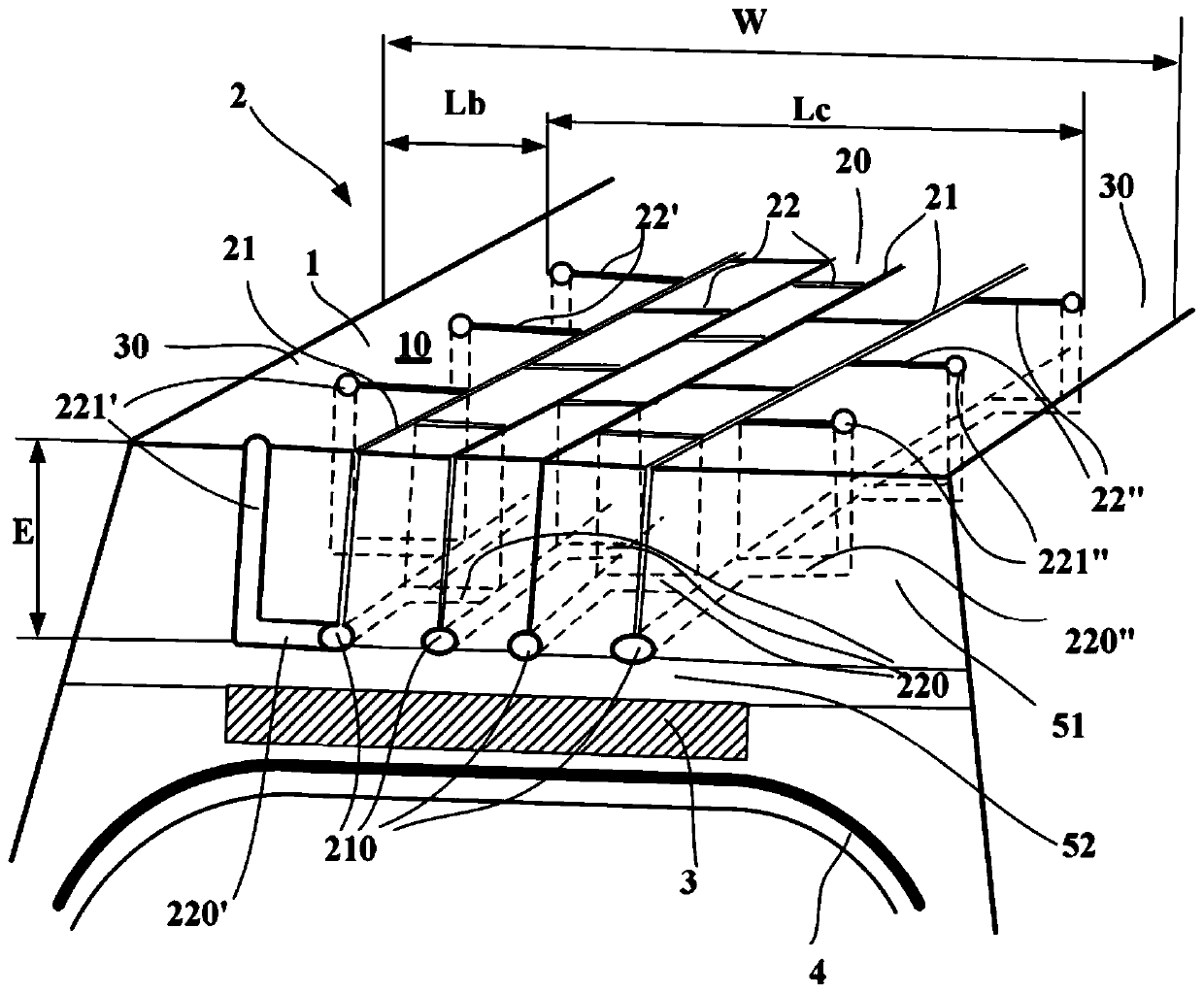

[0054] figure 1 Shown is part of a tire 2 of size 385 / 65R 22.5 intended to be mounted to a heavy trailer, comprising a carcass reinforcement 4 covered radially on the outside by a crown reinforcement 3 . This tire 2 also comprises a tread 1 formed according to the invention. This tread 1 has a total width W corresponding to the average width of the contact patch of the tire with the road surface obtained under the conditions of use of the tire at zero speed. In the case shown, this width W is equal to 310 mm.

[0055] The tread 1 is formed by a layer 51 made of a single material having a total thickness E equal to 14.3 mm, corresponding to the wearable value during the entire service life of the tire provided with the tread unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com