Thrust bearing seat of double-disk friction screw press

A friction press and thrust bearing technology, applied in the direction of presses, punching machines, bearing components, etc., can solve the problem of inconvenient replacement of the plane thrust bearing seat, and achieve the effect of convenient replacement of the bearing seat body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

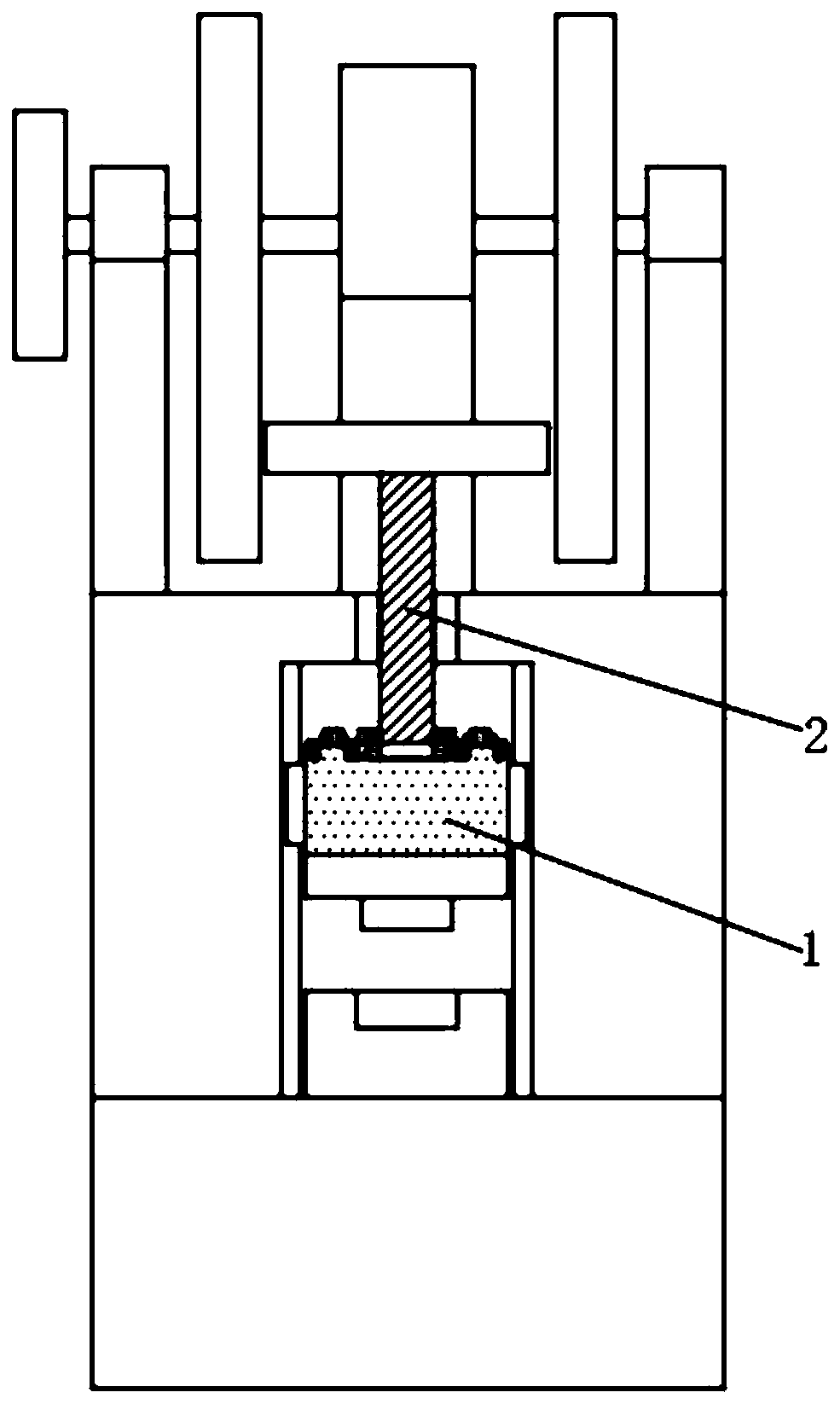

[0019] A thrust bearing seat of a double-disc friction press, comprising a movable mold base 1, a thrust screw 2 and a bearing housing body 3, the surface of the thrust screw 2 is fixedly connected to the inner wall of the bearing housing body 3, and the top of the movable mold base 1 is provided with Circular groove 4 and guide groove 12, guide groove 12 is several, and several guide grooves 12 are positioned at the left side and the right side of circular groove 4 respectively, and the quantity of guide groove 12 is corresponding with the quantity of guide bar 10, and the quantity of circular groove 4 The inner wall is movably connected with the surface of the bearing seat body 3, and the top of the movable die seat 1 is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com