X-shaped arm for vehicle air suspension and air suspension assembly based on X-shaped arm

An air suspension and vehicle technology, applied in suspension, vehicle parts, cantilevers installed on pivots, etc., can solve the problems of inability to bear lateral force, poor anti-rolling ability, and no anti-rolling ability, etc. Achieve the effect of improving turning stability, large anti-rolling ability and reducing the weight of the whole vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

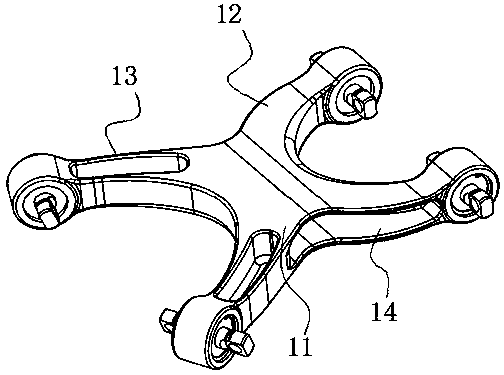

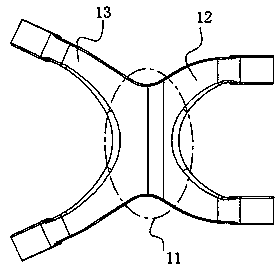

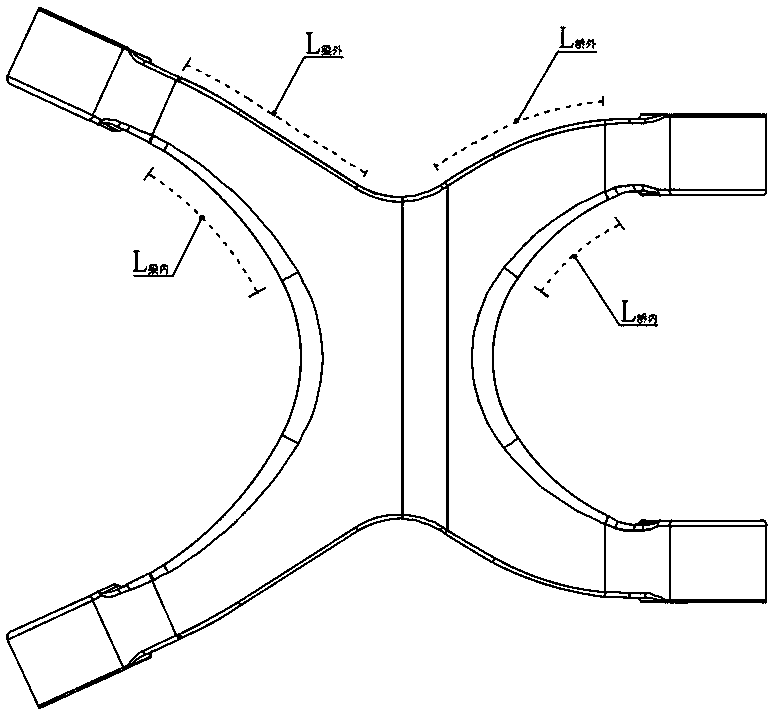

[0037] Such as Figure 1~4 As shown, the X-arm 1 for the vehicle air suspension of the present invention includes a body 11, and the body 11 is integrally formed with:

[0038] A pair of axle connecting arms 12 extending outward from the body 11 and arranged symmetrically, the end of the axle connecting arm 12 away from the body 11 is the axle connecting end; the axle connecting end has a mounting hole for connecting with the axle ;

[0039] A pair of beam connecting arms 13 extending outward from the body 11 and arranged symmetrically, the end of the beam connecting arm 13 away from the body 11 is a beam connecting end; the beam connecting end has a mounting hole for connecting with the beam;

[0040] The axis of symmetry of the axle connecting arm 12 coincides with the axis of symmetry of the crossbeam connecting arm 13, and the two axle connecting arms 12 and the two crossbeam connecting arms 13 are arranged opposite to each other on the axis of symmetry to form an X or H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com