Sludge collection device for sludge treatment

A collection device and sludge treatment technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, adsorption water/sewage treatment, etc., can solve problems such as inconvenient cleaning and low work efficiency, and increase utilization efficiency, reduce labor costs, and increase sludge treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

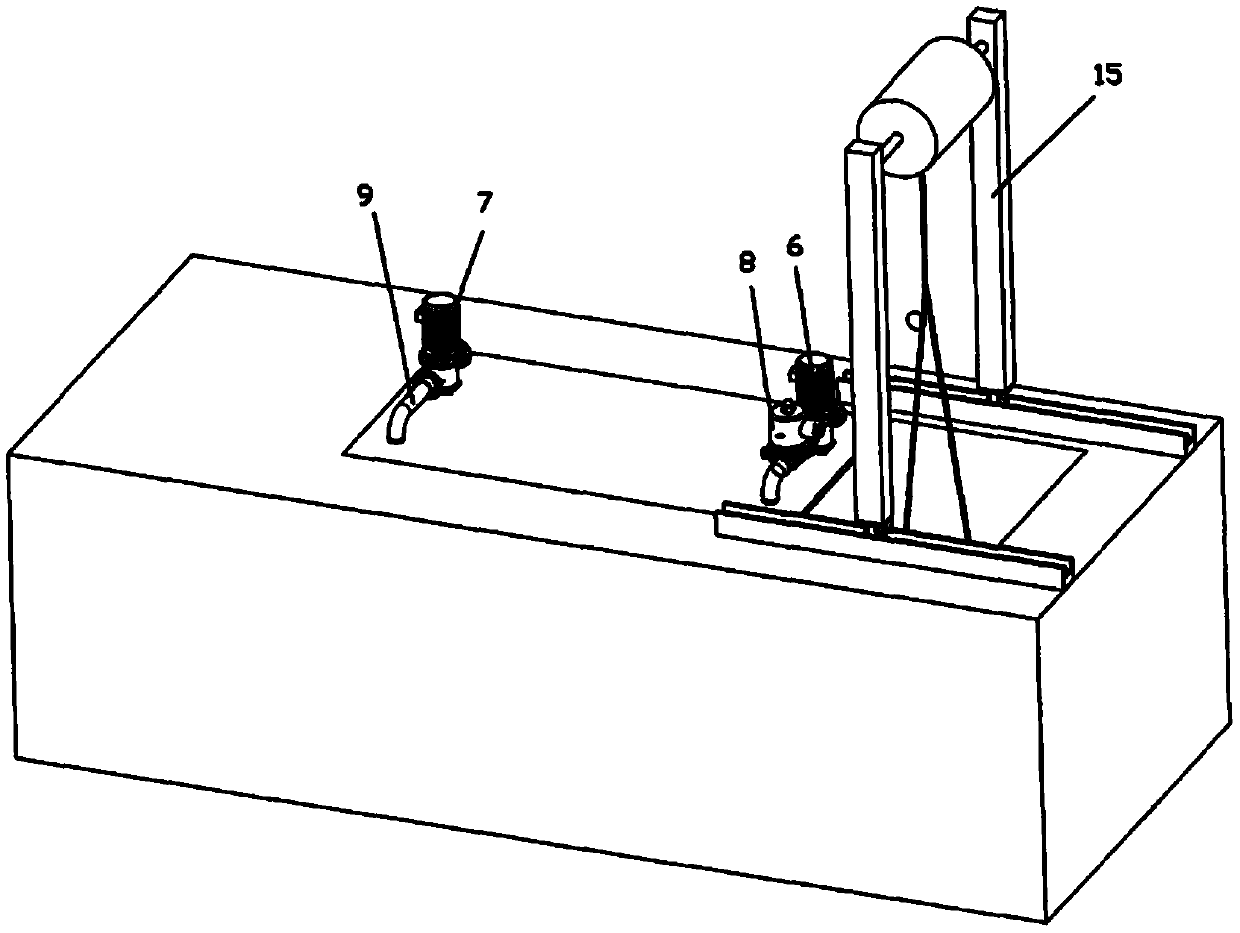

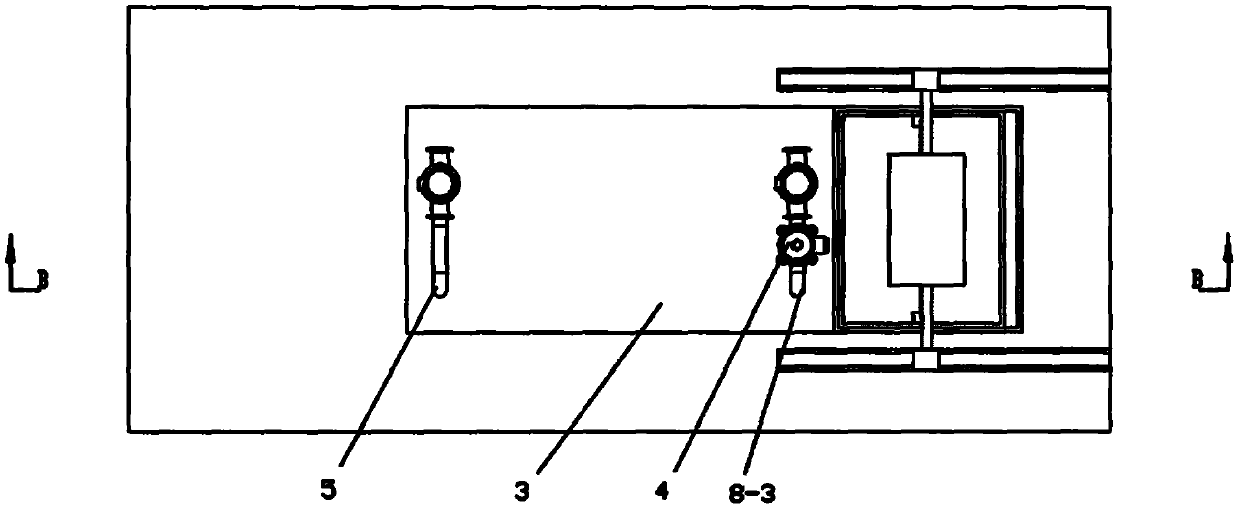

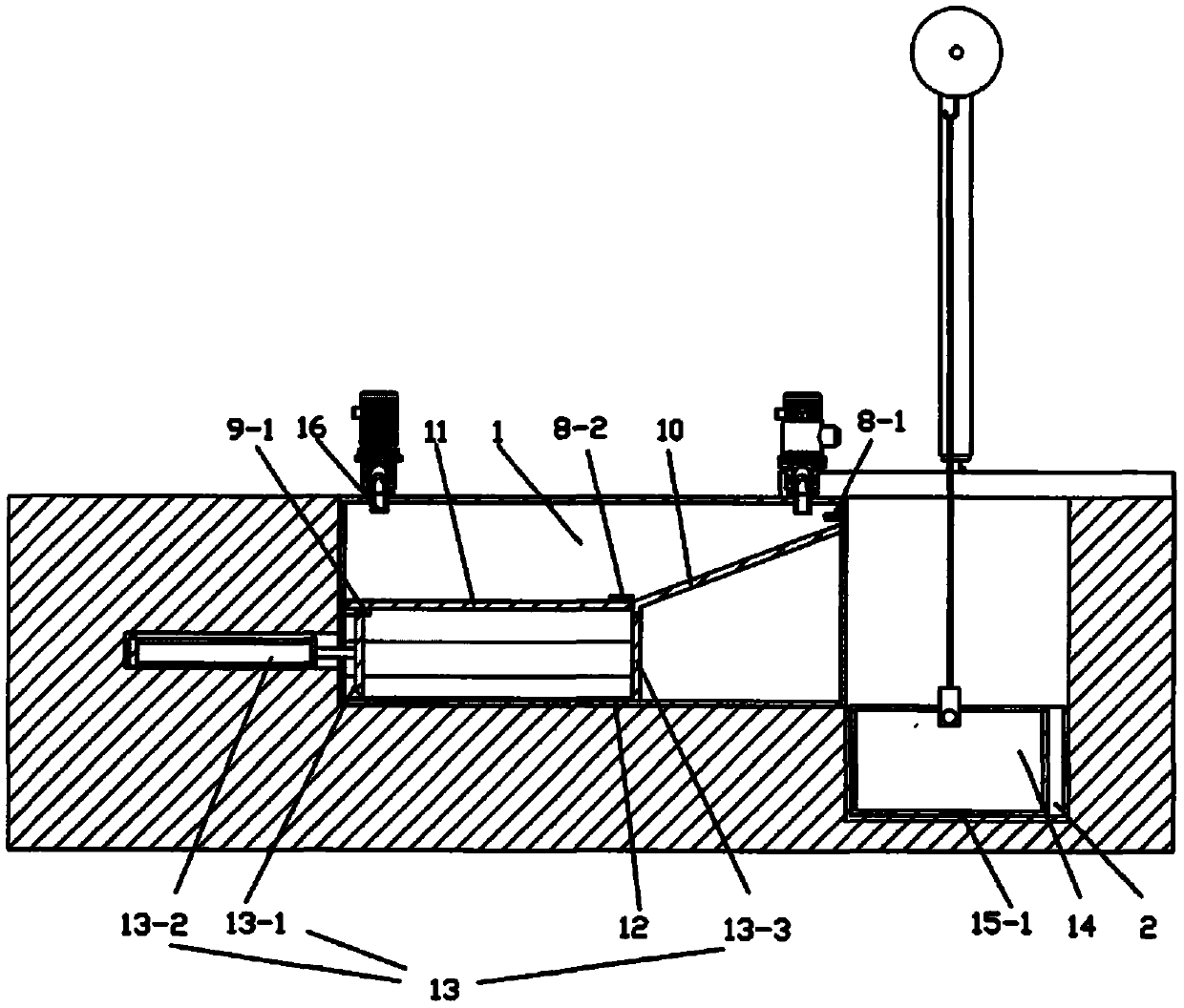

[0025] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0026] Please also refer to Figure 1 to Figure 4 , The sludge collection device for sludge treatment according to the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0027] The sludge collection device for sludge treatment includes a treatment pool 1 and a collection pool 2. The top of the treatment pool 1 is flush with the ground, and a cover plate 3 is fixed on the upper end of the treatment pool 1. The water inlet pipe 4 inside the pool and the water outlet pipe 5 for collecting water in the sludge, the water inlet pipe 4 and the water outlet pipe 5 are respectively connected to the outside of the first water pump 6 and the second water pump 7, and the 4 ends of the water inlet pipe are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com