A device and method for downhole drilling directional fracturing

A directional fracturing and fracturing technology, which is applied in the field of mine rock formation pressure, can solve the problems that the direction of the pressure valve is easy to deviate, cannot be adjusted, and the position of the pressure valve cannot be observed, so as to improve the scope of application, improve the accuracy of fracturing, and apply wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

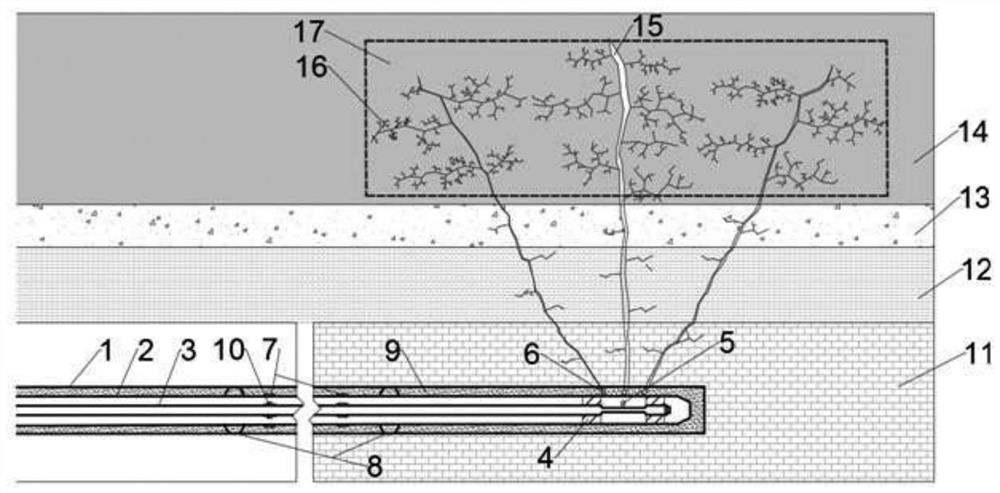

[0072]Such asfigure 1 As shown, when performing fan-shaped directional fracturing of coal seam 14 floor bore 1 in underground coal mines, the fracturing target area 17 is first determined according to coal seam 14 gas content, gas pressure, ground stress, and mining influence. According to the fracturing target area 17, select a suitable roadway closer to the target area, and construct a fracturing drill field in Xiangbang. Place the kilometer drill, drill pipe, casing 2, and fracturing pipe 3 near the working area to complete Preparation before fracturing construction.

[0073]The goal of fracturing in this embodiment is to perform pressure relief and drainage in the target area through floor fracturing. Therefore, it is required that the fracturing fractures can develop to the target area and at the same time spread through the entire fracturing target area 17 domains in a fan shape. Therefore, it is determined that this construction is a fan-shaped directional fracturing, and the fr...

Embodiment 2

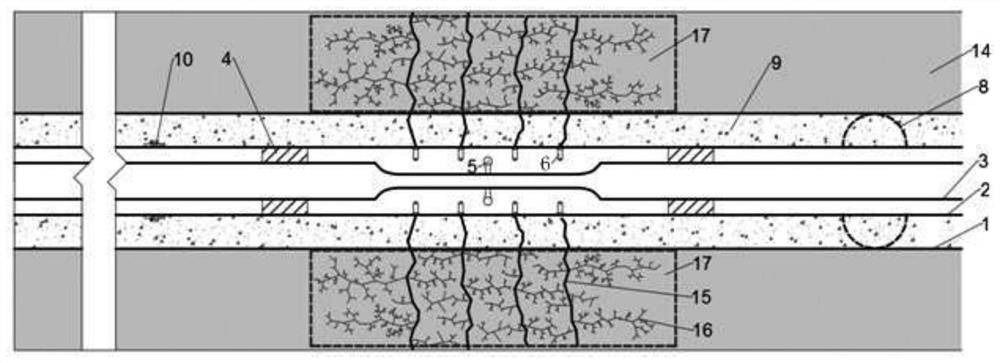

[0078]Such asfigure 2 As shown, when performing linear directional fracturing of the coal seam 14 borehole 1 in the coal mine, firstly, the fracturing target area 17 is determined according to the gas content of the coal seam 14, gas pressure, ground stress, and mining influence. Then, according to the fracturing target area 17, select the bottom tunnel or tunneling drill site closest to the target area to arrange the workbench, and place the tunnel drill, drill pipe, casing 2, and fracturing pipe 3 near the work area to complete the fracturing construction Preparation work before.

[0079]The goal of fracturing in this embodiment is to perform linear directional fracturing for the coal seam 14 to relieve pressure and increase permeability. Therefore, it is required that fractures develop along the coal seam 14 as much as possible. Therefore, cross directional fracturing was selected for this construction. According to the needs of cross directional fracturing, four water-soluble rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com