ring cylinder engine

An engine and ring cylinder technology, applied in the field of new engines, can solve the problem of low thermal efficiency of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

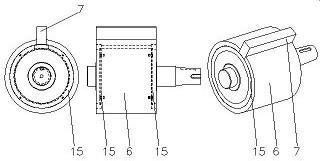

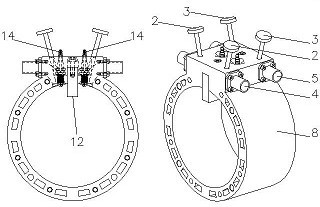

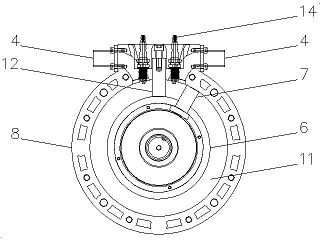

[0012] see Figure 1 to Figure 21 , in a preferred embodiment of the present invention, a ring cylinder engine comprises a cam rotor 6, a combustion chamber housing 8, a connecting rod 10, and a crankshaft 9, and is characterized in that: the cam rotor 6 is installed in the combustion chamber In the casing 8, the front end cover 17 and the rear end cover 18 are positioned, and the cam rotor 6 is divided into two left and right combustion chambers 11 by the combustion chamber shell partition 12 in the combustion chamber casing 8;

[0013] The rotation center of the cam rotor 6 is connected to one end of the rotor connecting block 13, the other end of the rotor connecting block 13 is hinged to one end of the connecting rod 10, and the other end of the connecting rod 10 is hinged to the drive arm of the crankshaft 9, The centerline of rotation of the crankshaft 9, the hinged centerlines at both ends of the connecting rod 10, and the centerlines at both ends of the rotor connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com