Whirlwind suction garbage incinerator

A waste incinerator and cyclone technology, applied in the direction of incinerator, combustion method, combustion type, etc., can solve problems such as obstructed air, increased pressure, environmental pollution, etc., and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

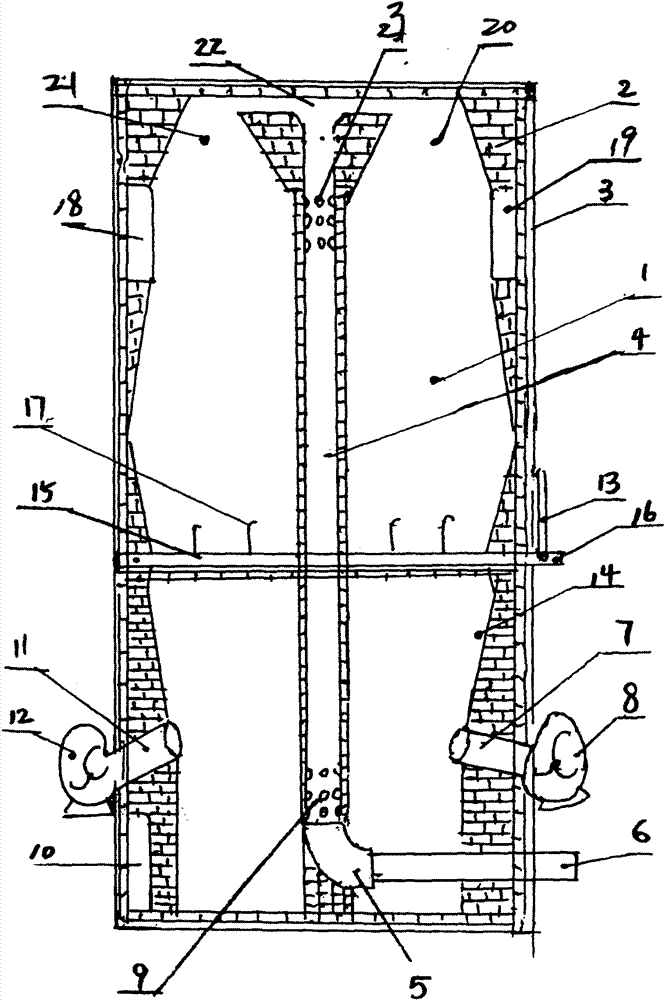

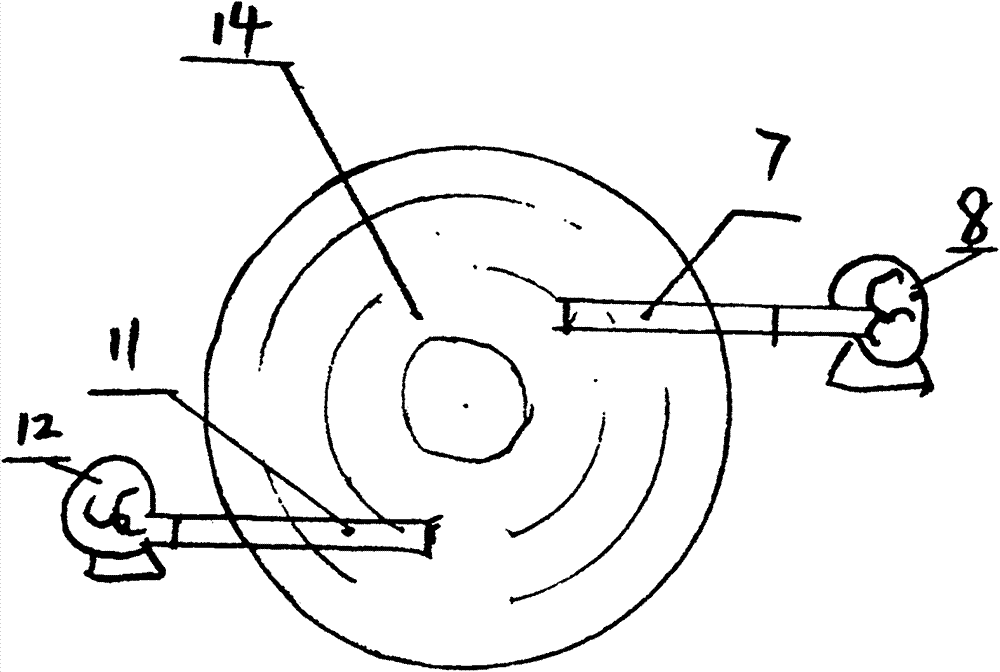

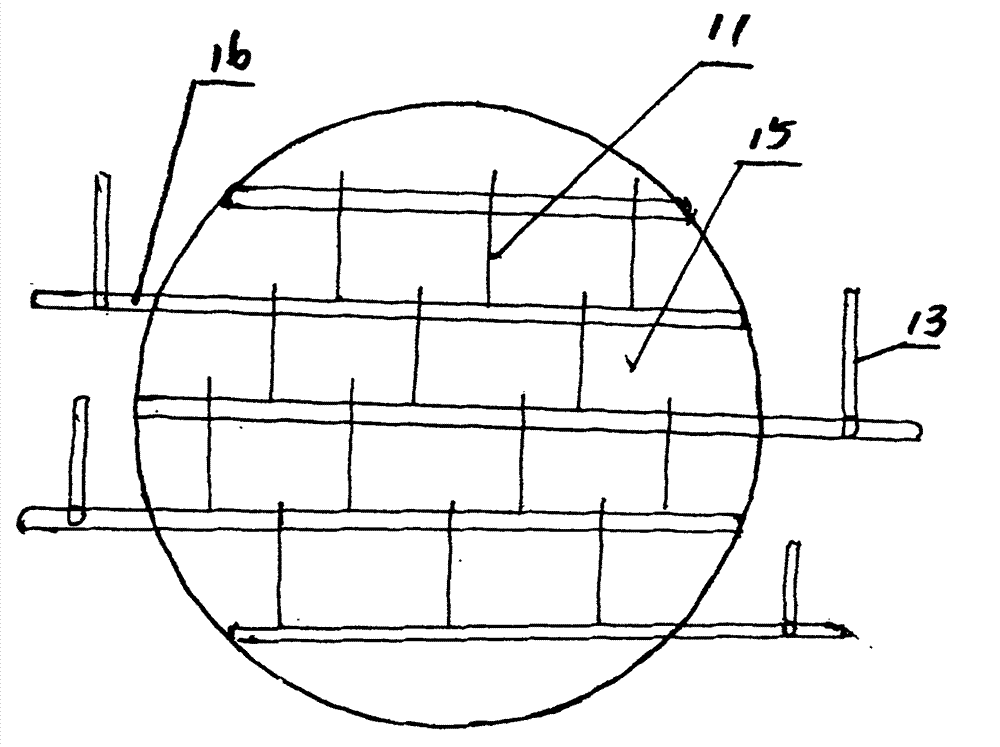

[0011] [specific implementation plan]

[0012] Embodiments are further described in a preferred manner below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the present invention is a cylindrical shape erected as a whole. The entire furnace body 1 is made of refractory bricks 2, and the outer layer is covered with a heat insulating layer 3 such as asbestos. The difference between the chimneys in the prior art is that the chimney of the present invention is divided into a right chimney 20 and a left chimney 21. The outlet of the chimney is not set upwards as the top, but is connected by a steel pipe 4 installed in the center of the furnace, that is, two chimneys 20, 21 The air ducts at the top are combined and connected with the central steel pipe 4 to form an air cycle from bottom to top and from top to bottom; the outlet of the steel pipe 4 is set at the lower part, and the elbow 5 is used to connect the exhaust pipe 6 to discharge outward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com